Pipeline assembly production process

A production process and pipeline technology, applied in image data processing, special data processing applications, instruments, etc., can solve the problems of difficulty in ensuring the accuracy of the comparison device, difficulty in the manufacture of the comparison device, affecting the detection results, etc., to achieve high market promotion value, Solve the effect of taking too long to detect and save processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

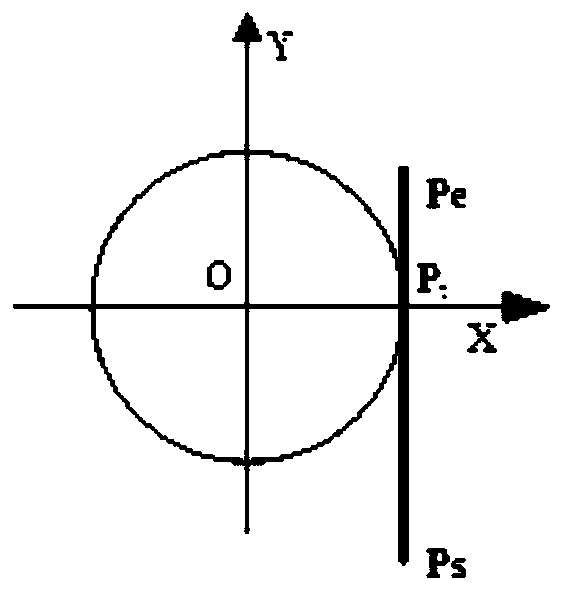

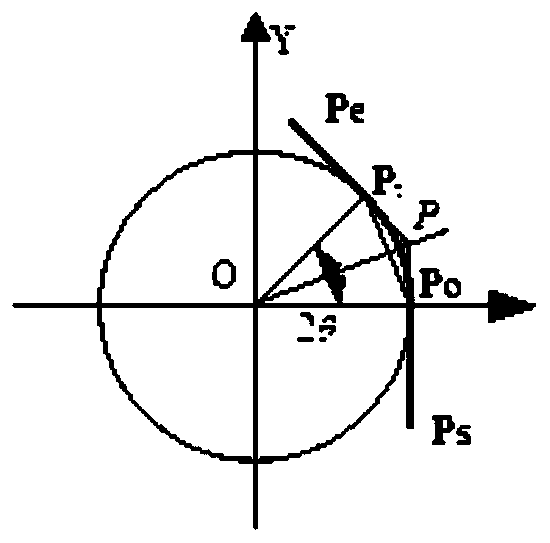

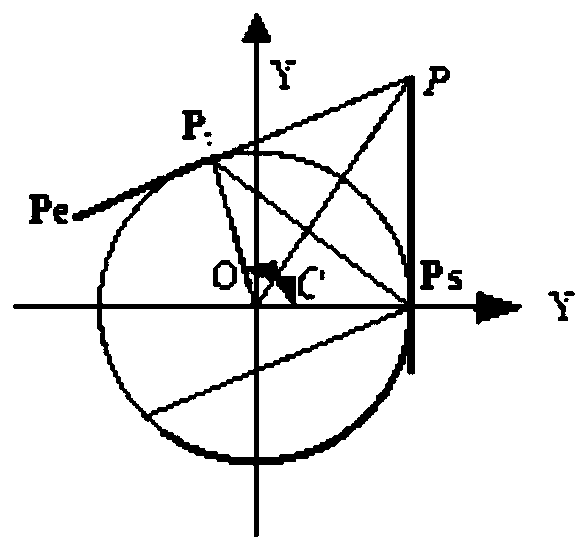

[0055] combined with Figure 4~7 , a pipeline component production process, including pipeline information extraction and output module, pipeline manufacturability intelligent evaluation module, pipeline batch processing process simulation module, conduit and pipeline connector scoring module, conduit shape detection module and Tube assembly detection module.

[0056] The pipeline information extraction and output module includes: using the secondary development technology of 3D modeling software such as PROE and CATIA to carry out secondary development of 3D modeling software such as PROE and CATIA; using the secondary development results of the 3D software to traverse The topological structure of the catheter model obtains geometric information such as the number of segments of the catheter, the center point of each section, the length of each straight lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com