Voltage transformer with air duct cooling and secondary fusing

A technology of voltage transformers and air ducts, applied in the direction of inductors, transformer/inductor cooling, transformer/inductor magnetic cores, etc., can solve the problems of difficult transformer replacement, unsatisfactory heat dissipation performance, complicated wiring, etc. The effect of burning or bursting, reducing subsequent effects, and increasing the speed of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

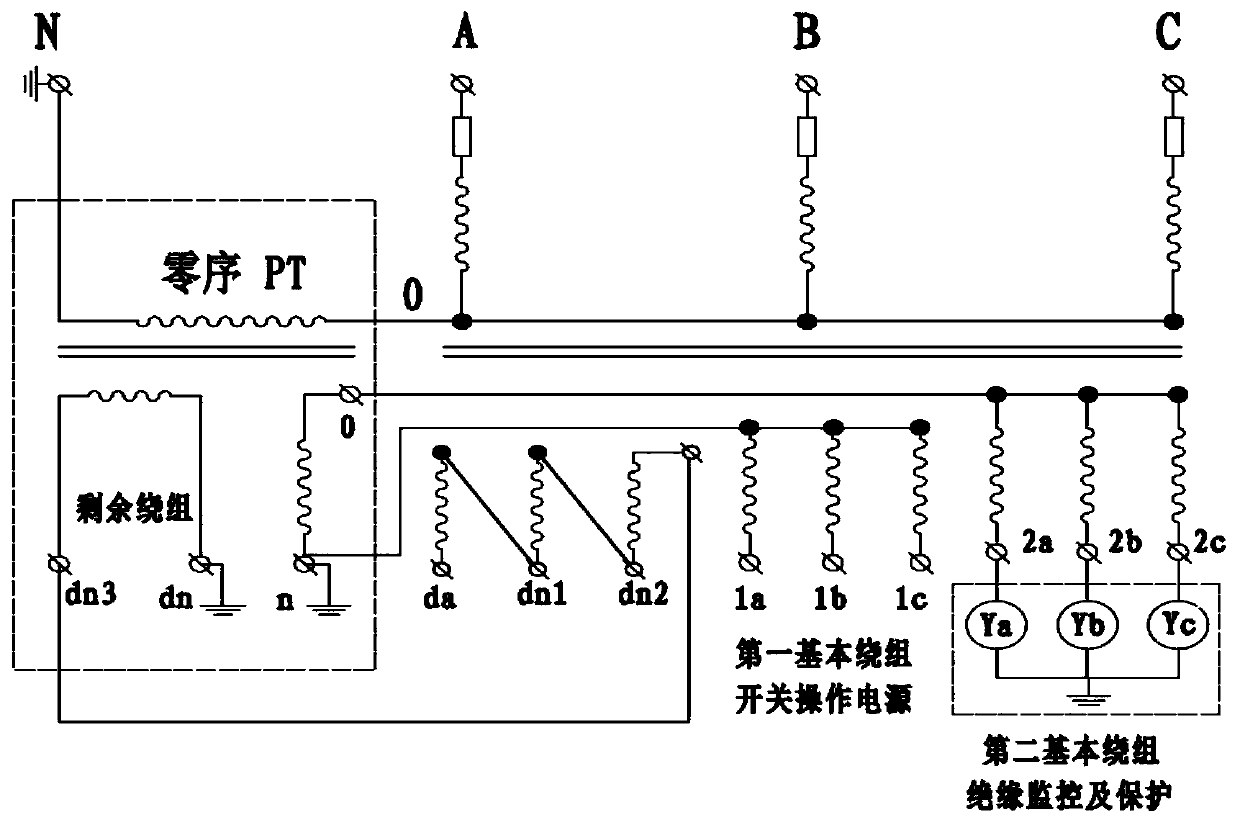

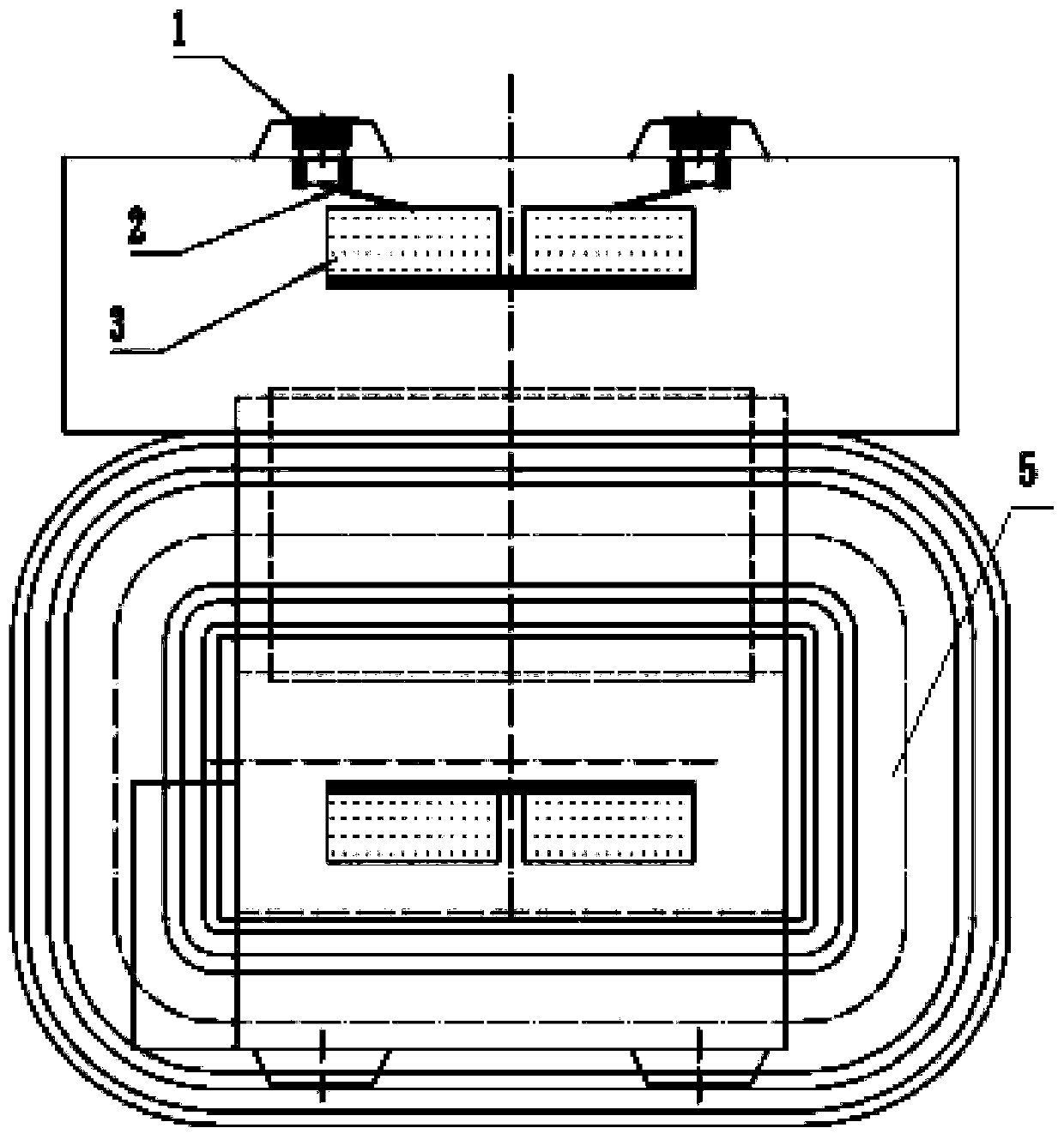

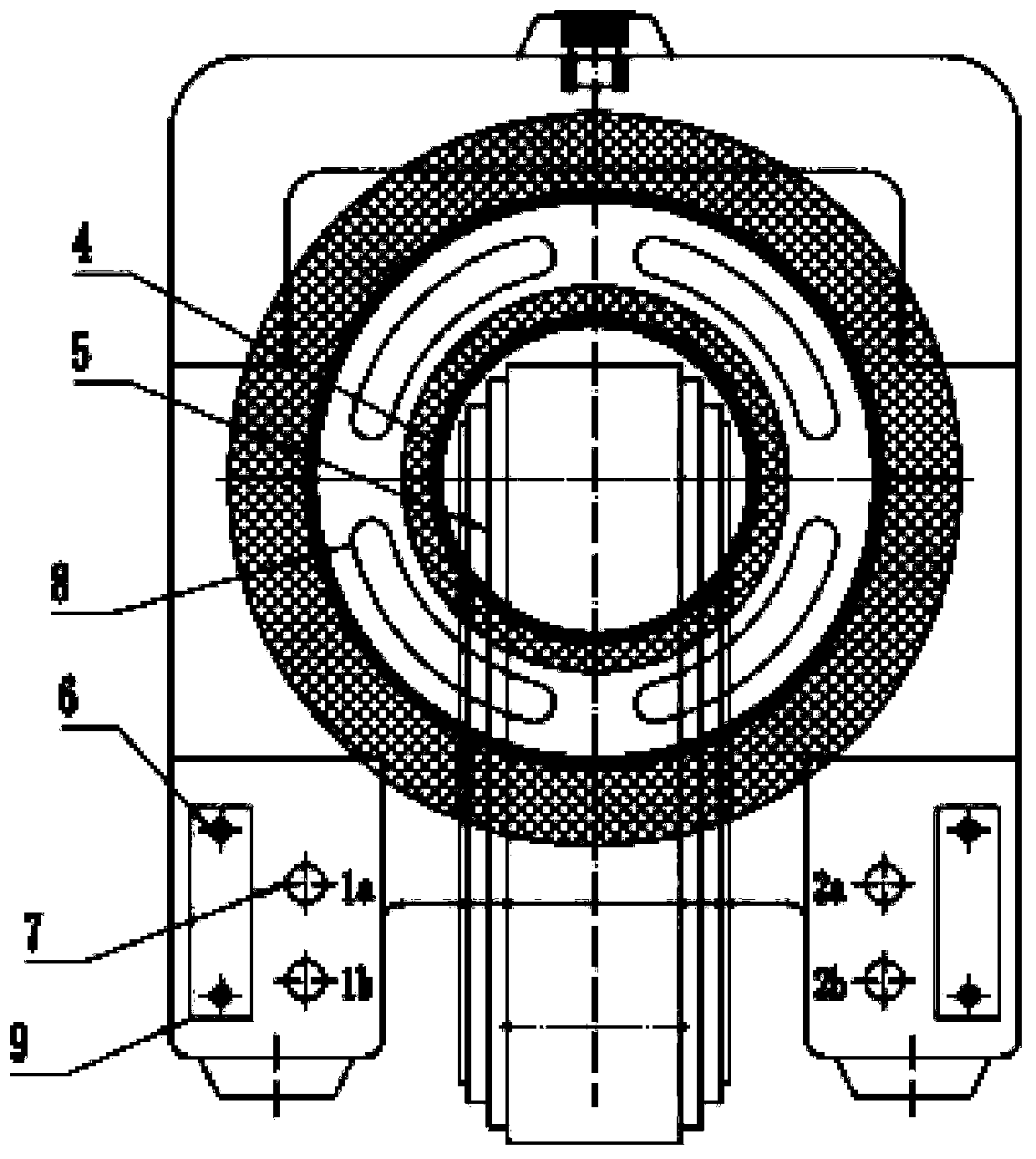

[0024] see Figure 2-3 , a voltage transformer with air duct heat dissipation and secondary fusing, including a secondary coil 4 located in the primary coil 3, the secondary coil 4 is hollow inside and is interspersed with a ring-shaped iron core 5, and the lower end of the iron core 5 is wrapped Below the bottom of the primary coil 3, on the top of the primary coil 3 there is a primary coil hoisting bracket 2 welded to it by soldering, on the top of the primary coil hoisting bracket 3 there is a primary M10 insert 1, and there are two primary M10 inserts 1 And all are welded with the primary coil 3 through the conductive copper sheet, and the secondary melting pipe structure 9 is welded and connected to the bottom of the primary coil 3, and the secondary melting pipe structure 9 includes the secondary melting pipe insert 6 and the secondary melting pipe insert. The secondary outlet insert 7 on part 6, when installing, one end of the primary M10 insert 1 is connected to the hi...

Embodiment 2

[0030]The difference from Embodiment 1 is that the iron core 5 is an exposed structure on both sides. This design can make it dissipate the heat generated by the ferromagnetic resonance of the voltage transformer at the fastest speed, the existence of the air duct structure 8 and the existence of the iron core. 5 The exposed installation method can greatly improve the heat dissipation capacity of the transformer itself, thereby reducing the temperature rise of the transformer to a certain extent, thereby improving the load carrying capacity of the transformer to a certain extent, and increasing the capacity of the transformer performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com