Aluminum pot with inner and outer bottoms as well as manufacturing method thereof

A manufacturing method and technology of aluminum pans, which are applied to special materials for cooking utensils, cooking utensils, household appliances, etc., can solve the problems of easy deformation and heat energy conversion rate, and achieve good wear resistance of the inner bottom, high heat conduction efficiency, and good thermal stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

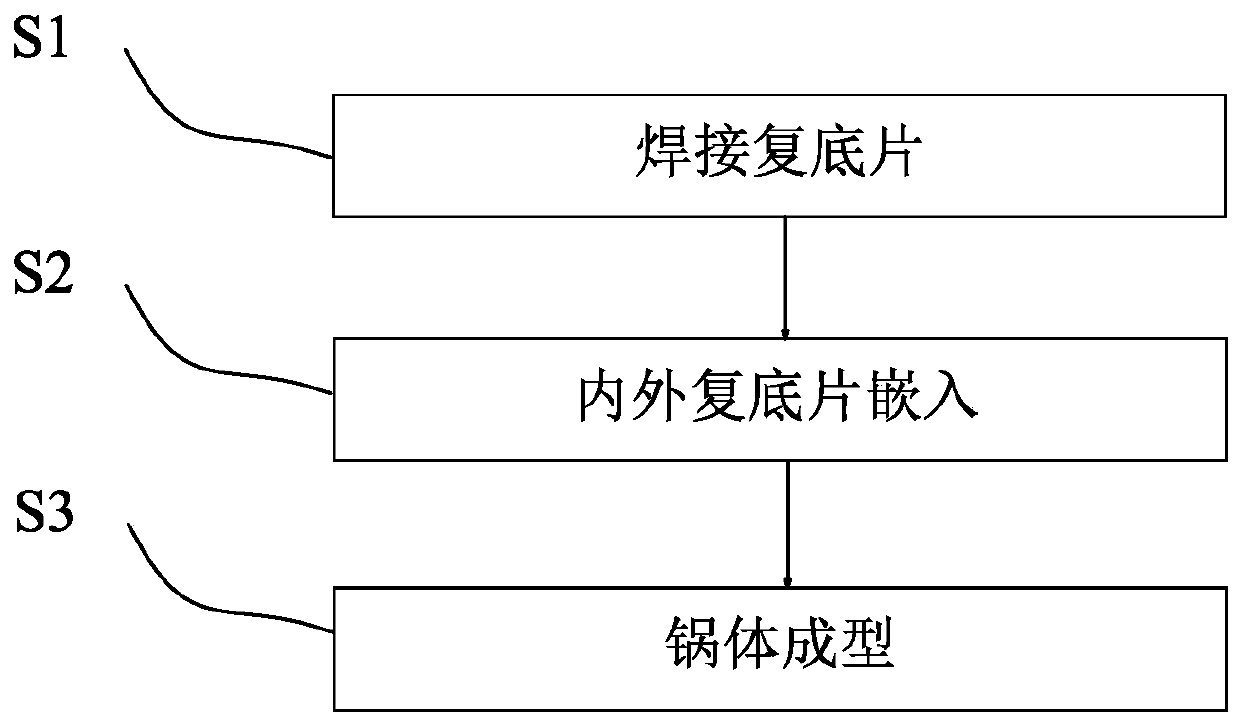

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

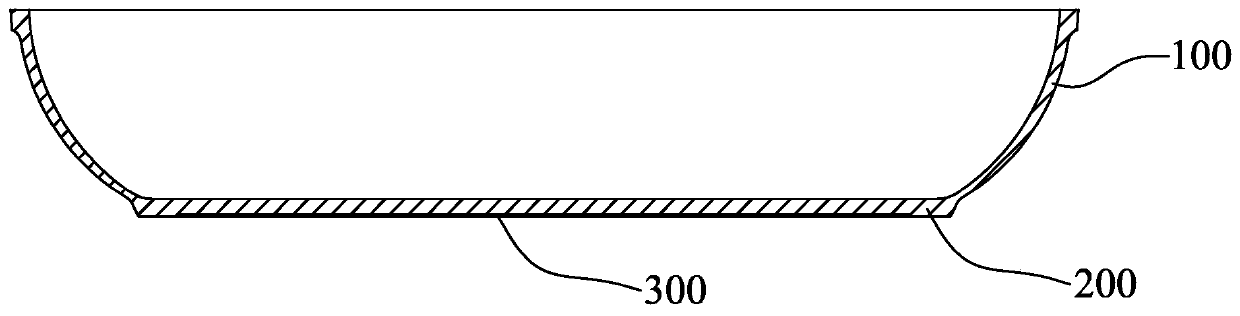

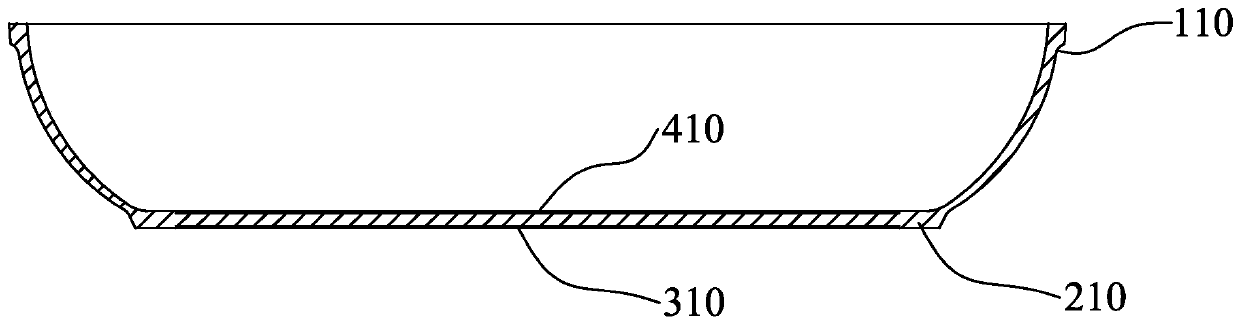

[0026] Such as figure 2 As shown, the aluminum pot with inner and outer double bottoms of the present invention includes a pot body, and the pot body includes a pot wall 110 and a pot bottom 210, and an inner magnetic conductive sheet 410 is compounded on the upper surface of the pot bottom 210, and a compound inner magnetic sheet 410 is compounded on the lower surface of the pot bottom 210. There is an outer magnetic sheet 310. Both the inner magnetically conductive sheet 410 and the outer magnetically conductive sheet 310 can be stainless steel sheets, iron sheets or other magnetically conductive sheets with magnetically conductive properties. The pot body is made of aluminum alloy with good rust resistance, preferably 3003 series aluminum alloy, and the inner magnetic sheet 410 is made of a magnetic material with good corrosion resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com