Convenient-to-maintain bus-bar cast-welding mould capable of beating heated quickly

A technology for convenient maintenance and casting and welding molds, which is applied in the field of molds, can solve the problems of heating or cooling, rapid uniformity, etc., and achieve the effects of convenient local maintenance and replacement, improving casting and welding quality, and reducing casting and welding time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

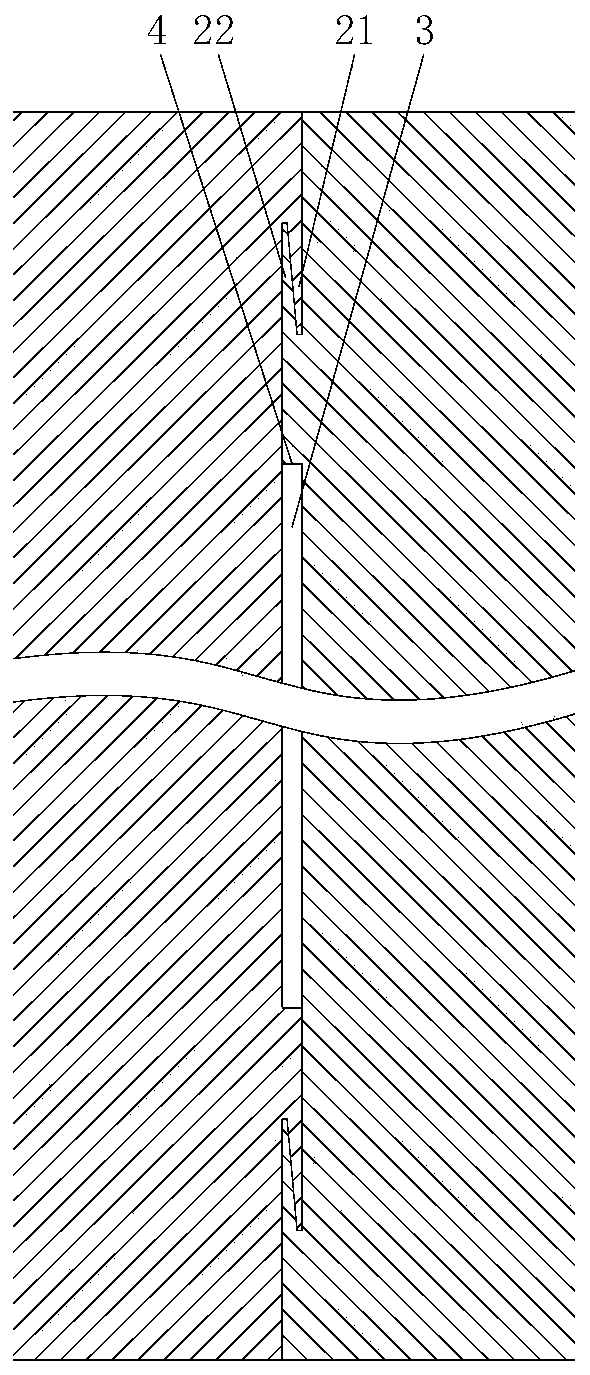

[0036] Such as image 3 As shown, the left hook 21 and the right hook 22 are set at the same width as the molding unit 11, and the openings of the left hook 21 and the right hook 22 are oppositely facing and correspondingly protruding from one end surface of two adjacent molding units 11. The left hook 21 and the right hook 22 are hooked correspondingly, so as to tightly connect the end faces of two adjacent forming units 11 to form a waterproof surface 4, and between the left hook 21, the right hook 22 and the adjacent two forming units 11 The gap channel 3 is formed by enclosing one end surface.

[0037] The left hook 21 and the right hook 22 are two pairs, and the two pairs of the left hook 21 and the right hook 22 respectively protrude from the upper and lower parts of one end surface of two adjacent molding units 11, and the left hook 21 and the right hook 22. The opening faces the opposite direction, and the two pairs of left hooks 21 and right hooks 22 are hooked corre...

Embodiment 2

[0039] Such as Figure 4 As shown, the hooking structure 2 also includes a connecting plate 23 set at the same width as the forming unit 11, and the left hook 21 and the right hook 22 are opened on the top of one end of two adjacent forming units 11 with their openings facing upwards. The lower surface of the connecting plate 23 is respectively provided with two connecting hooks 24 corresponding to the left hook 21 and the right hook 22, and the connecting plate 23 is embedded and connected between the left hook 21 and the right hook 22 by the two connecting hooks 24, so as to The upper parts of one ends of two adjacent molding units 11 are tightly connected to form a waterproof surface 4 , and the gap channel 3 is formed by enclosing the connection plate 23 and one end surface of two adjacent molding units 11 .

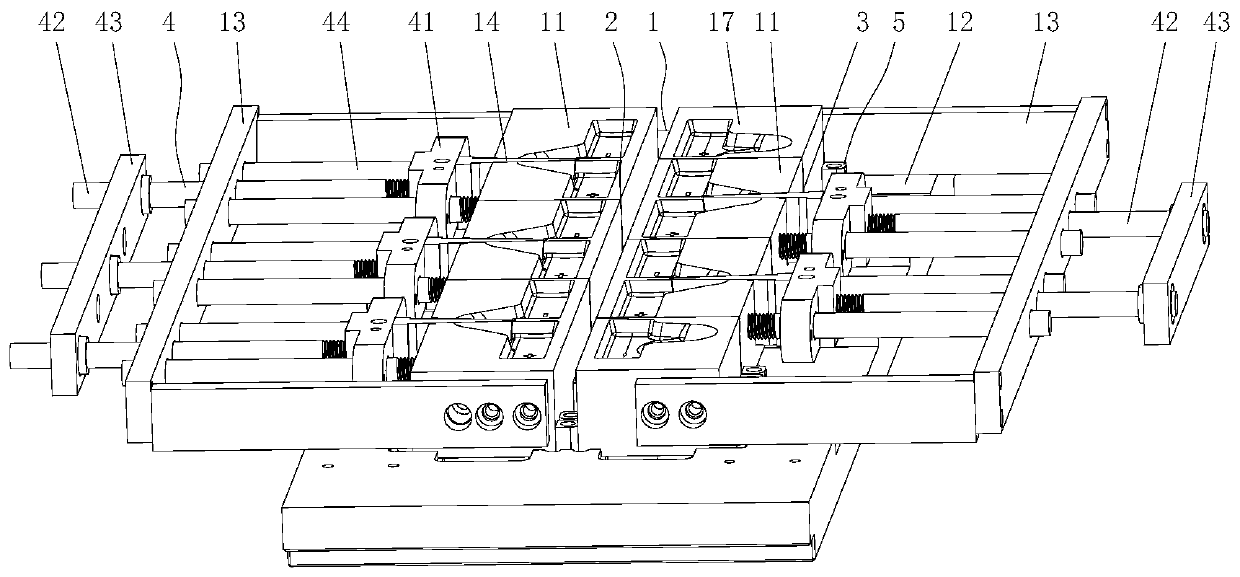

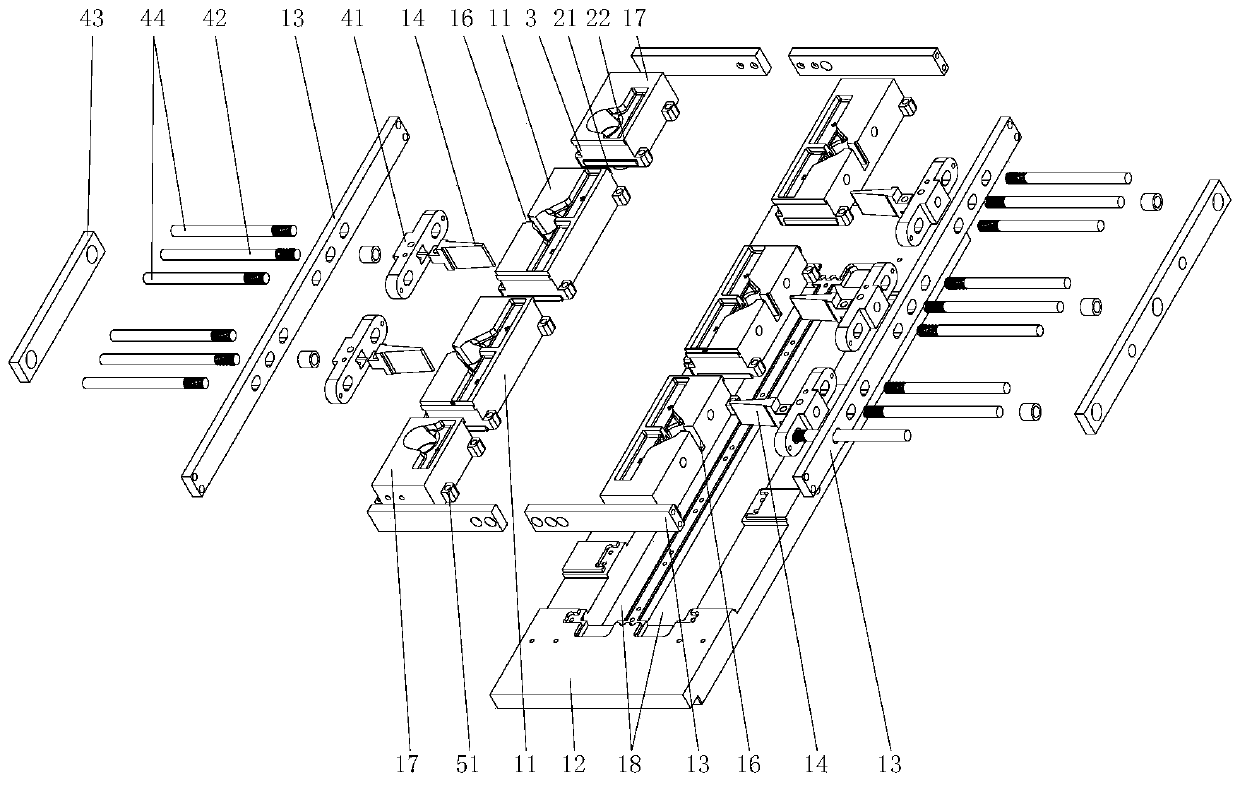

[0040] The present invention adopts the above technical scheme to separate and modularize the molding unit 11, the separator 14 and the push-pull structure 4 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com