Welding machine transmission mechanism capable of transmitting large-sized silicon wafers

A transmission mechanism, large-scale technology, applied in the direction of conveyor objects, transportation and packaging, climate sustainability, etc., can solve the problems of inability to meet the transmission requirements of large-scale solar cells, unstable transmission, and low fragmentation rate, to avoid The effect of silicon wafer size deformation, reducing deformation and falling, and reducing fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

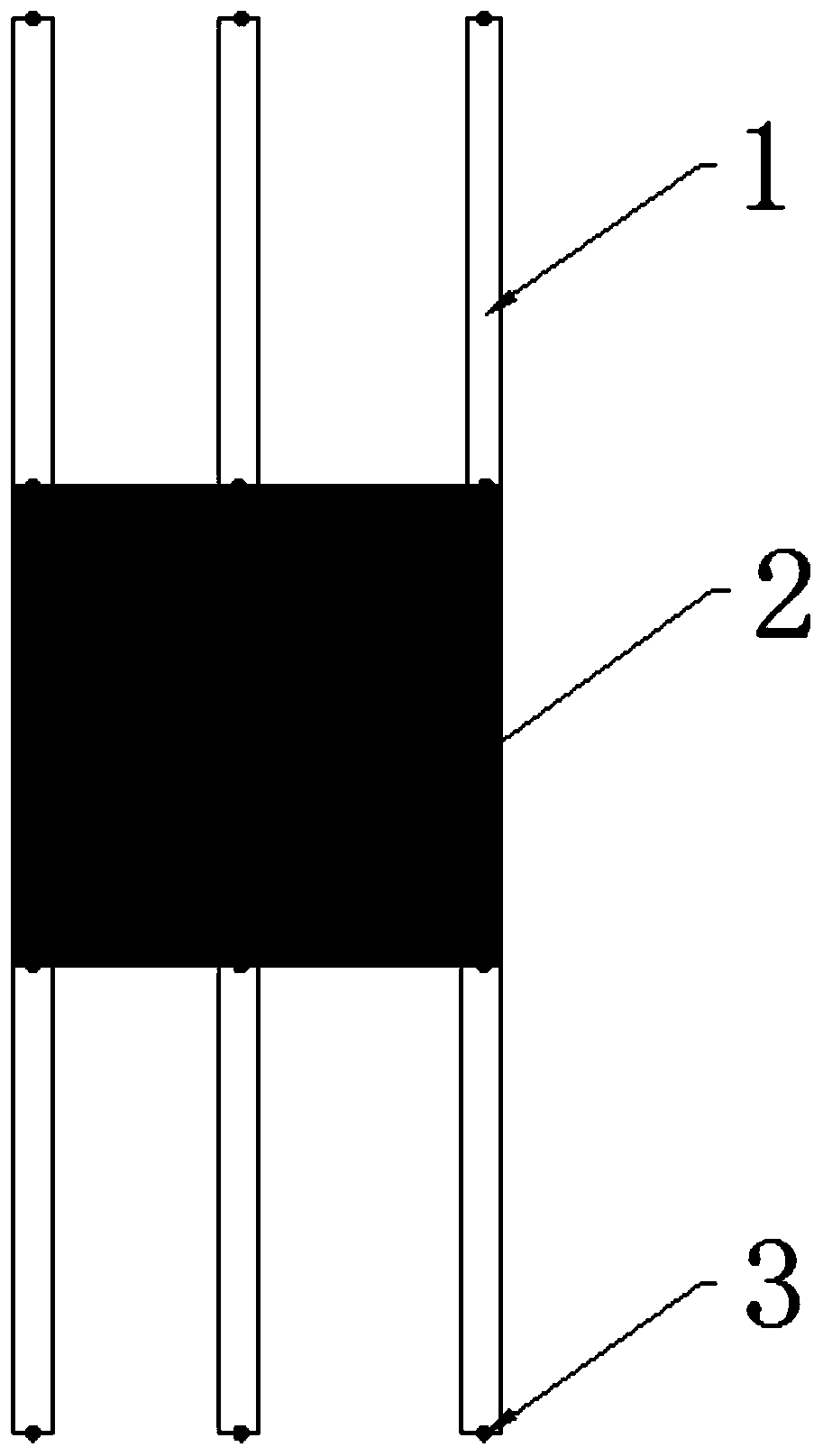

[0030] A welder transfer mechanism that can transfer large-size silicon wafers, such as figure 1 and image 3 As shown, it includes a transmission device and a positioning device 3, wherein the positioning device 3 is adjustable on the transmission device, the distance between adjacent positioning devices 3 can be adjusted, and the distance between adjacent positioning devices is the same as that of the silicon wafer 2 The size is adapted to facilitate the positioning and transmission of the silicon wafer 2. During the transmission process of the silicon wafer 2, the feeding sucker places the silicon wafer on the transmission device, and the silicon wafer 2 is placed between the adjacent positioning devices 3, and the silicon wafer 2 is positioned when it is transported on the transmission device, so as to avoid silicon The chip shakes, the precise positioning of the silicon chip is convenient for the loading sucker to load, realizes accurate loading and transportation, and a...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 lies in the difference in the transmission structure, and the rest of the structures are the same. In this embodiment, the transmission structure will be described in detail, and the rest will not be repeated.

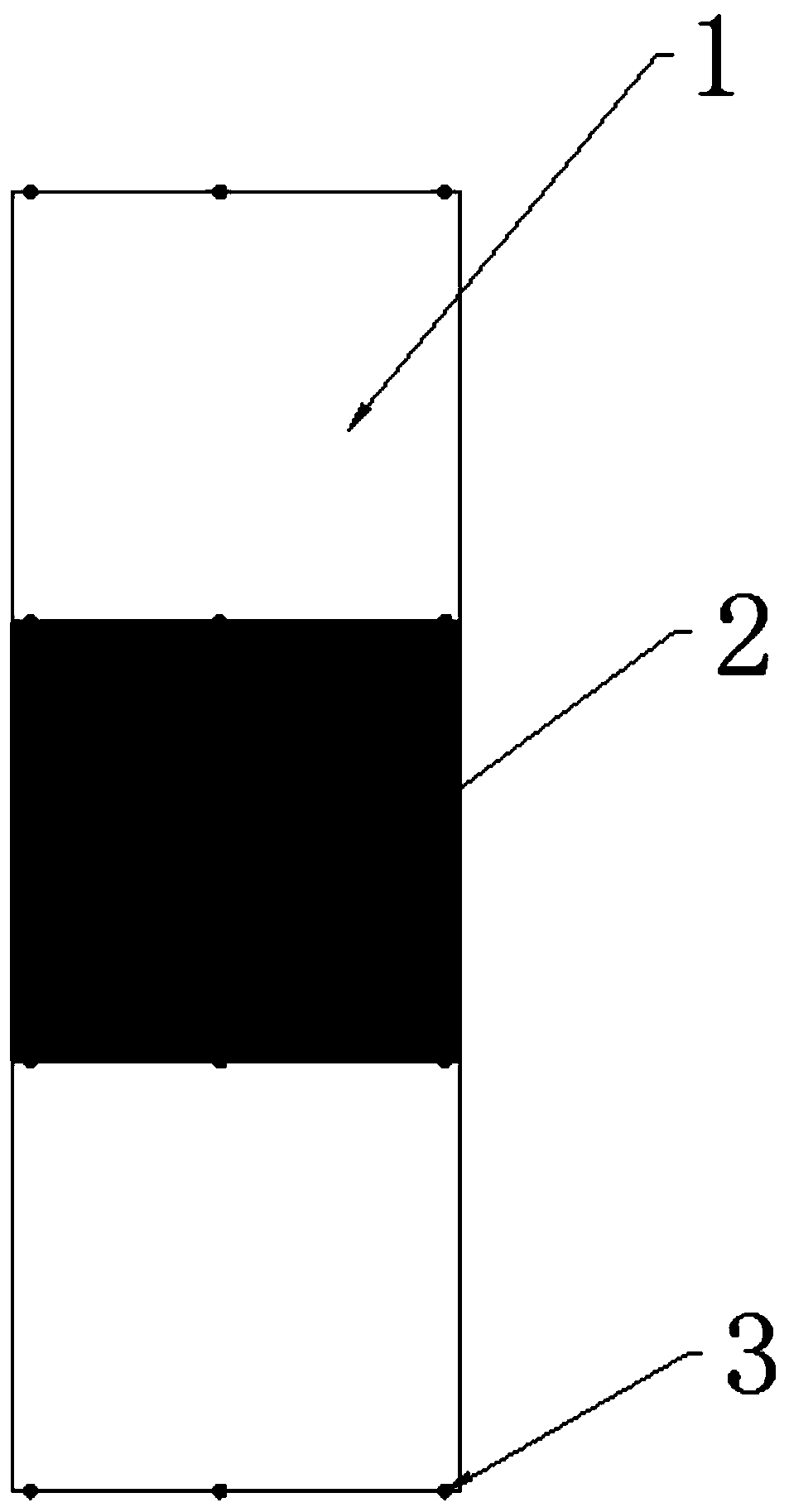

[0045] In this example, if figure 2As shown, the above-mentioned transmission device is a transmission belt 1, the width of the transmission belt 1 is greater than the width of the silicon wafer 2, the transmission belt 1 is a transmission belt 1 with a certain width, and the width of the transmission belt 1 is the same as the width of the silicon wafer 2 Compatible, easy to transport silicon wafers. A plurality of positioning devices 3 are installed at equal intervals on the conveyor belt 1, and the spacing is adapted to the size of the silicon wafer 2, which is convenient for feeding and transporting the silicon wafer 2; in the width direction of the conveyor belt 1, a positioning device is installed 3,...

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 and Embodiment 2 lies in the difference in the structure of the positioning device, and the rest of the structures are the same. In this embodiment, the structure of the positioning device will be described in detail, and the rest will not be repeated.

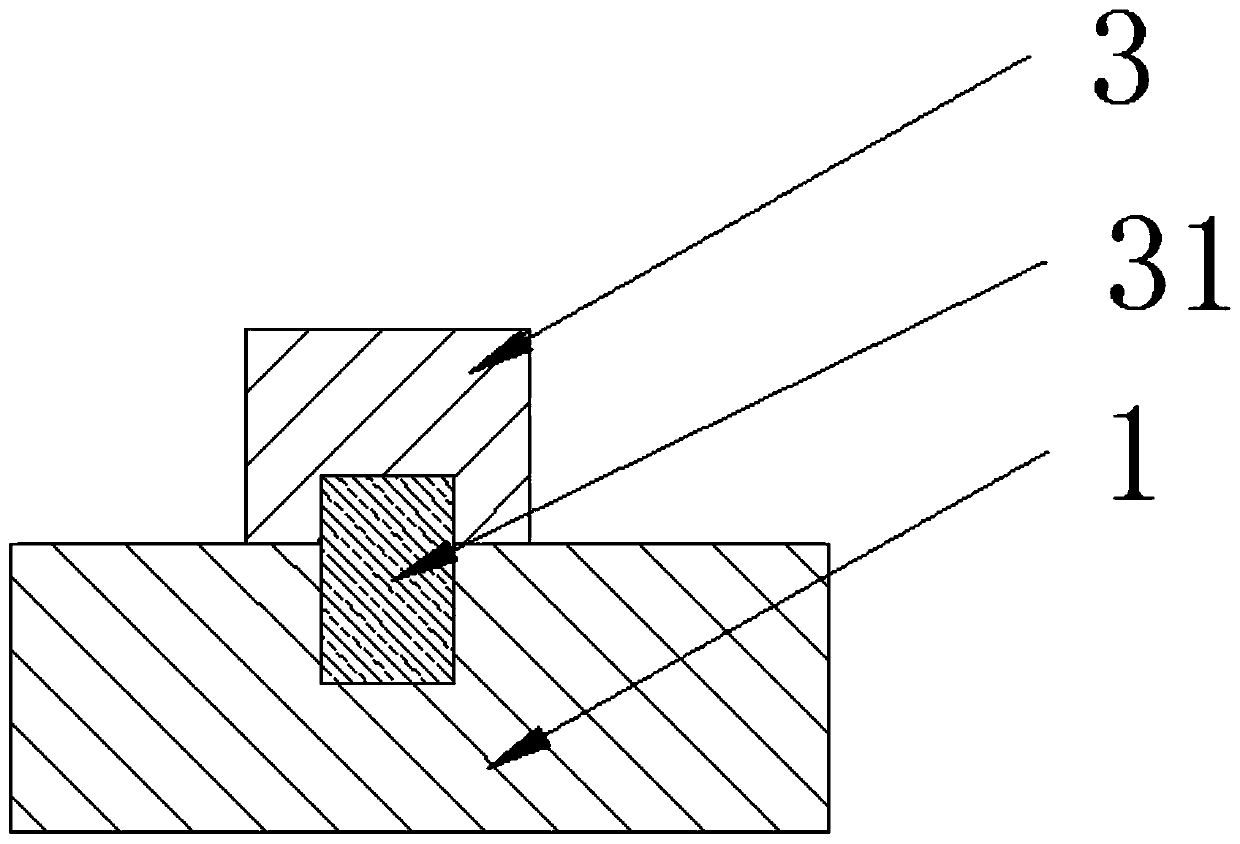

[0049] In this example, if Figure 4 As shown, the positioning device 3 is a positioning block, one end of the positioning block is equipped with a plug-in device 32, the free end of the plug-in device 32 is a tip, the plug-in device 32 is plugged on the conveyor belt 1, and the plug-in device The free end of 32 will not penetrate the transmission belt 1, and the positioning block is fixedly installed on the transmission belt 1. The plug-in device 32 is a pin, and the number of pins can be one, or two, or more One, select according to actual needs, no specific requirements are made here; use the plug-in device 32 to install the positioning blocks, so that the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com