A three-dimensional ultrasonic nano-vibration assisted processing platform

A three-dimensional ultrasonic and auxiliary processing technology, applied in metal processing equipment, fluid using vibration, metal processing mechanical parts, etc., can solve the problems of limited processing fineness, limited processing depth, low processing speed, etc., to improve the first-order inherent frequency, damage prevention, the effect of eliminating bending moments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

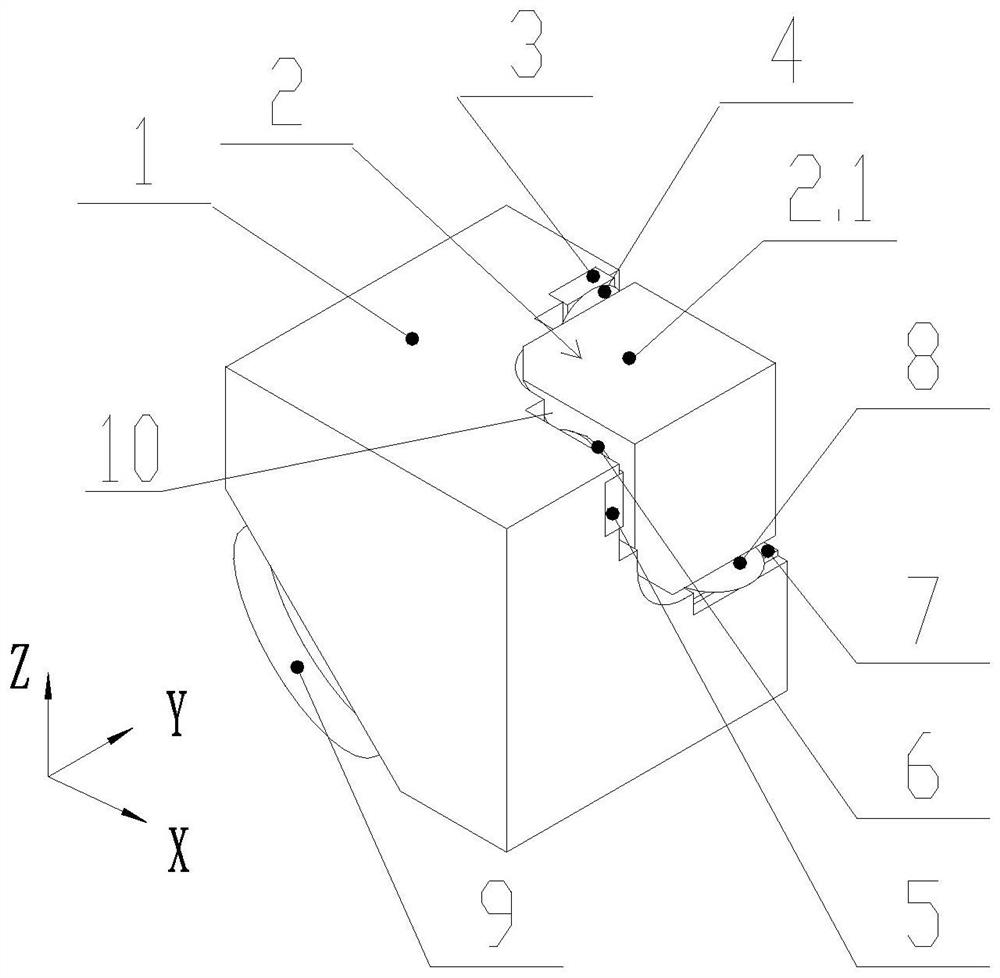

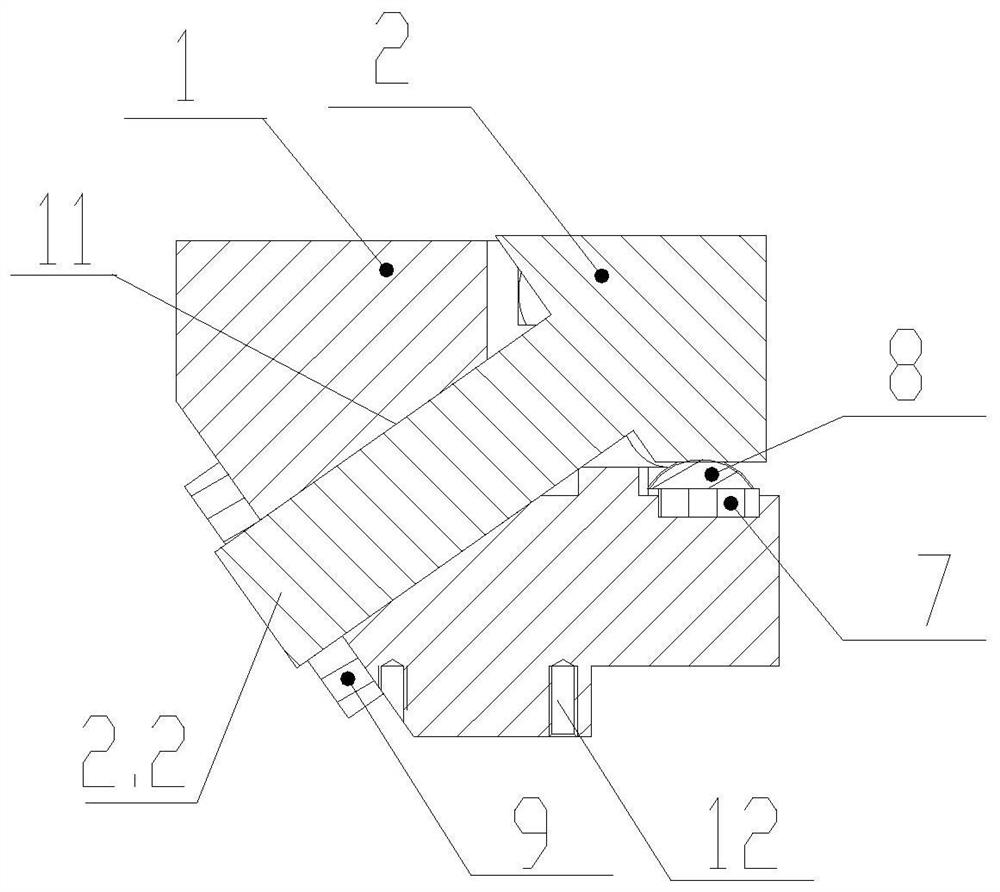

[0019] A three-dimensional ultrasonic nano-vibration assisted processing platform of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0020] Such as figure 1 , figure 2 As shown, a three-dimensional ultrasonic nano-vibration assisted processing platform of the present invention includes a rectangular body base 1, and an ultrasonic vibration platform 2 is arranged between an upper corner of the rectangular body base 1 and a symmetrical lower corner. , the platform end 2.1 of the ultrasonic vibration platform 2 is embedded in the upper corner, the tail end 2.2 of the ultrasonic vibration platform 2 is connected to the lower corner by a pre-tightening nut 9, and the platform end 2.1 and The rectangular base 1 is an interference fit, and the platform end 2.1 is respectively provided with a group of vibration mechanisms for providing vibration for the ultrasonic vibration platform 2 between the surfaces adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com