Single unit rotation type combined gas explosion sound source

A rotary and air-explosion technology, applied in the field of anti-mine, can solve the problems of complex control, large weight and size, complex structure, etc., and achieve the effects of adjustable amplitude, improved operating efficiency, and reduced mine-sweeping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

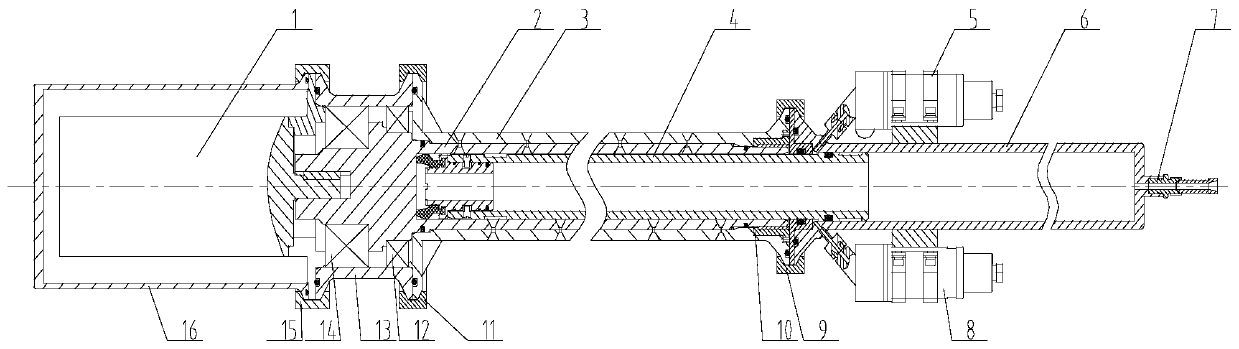

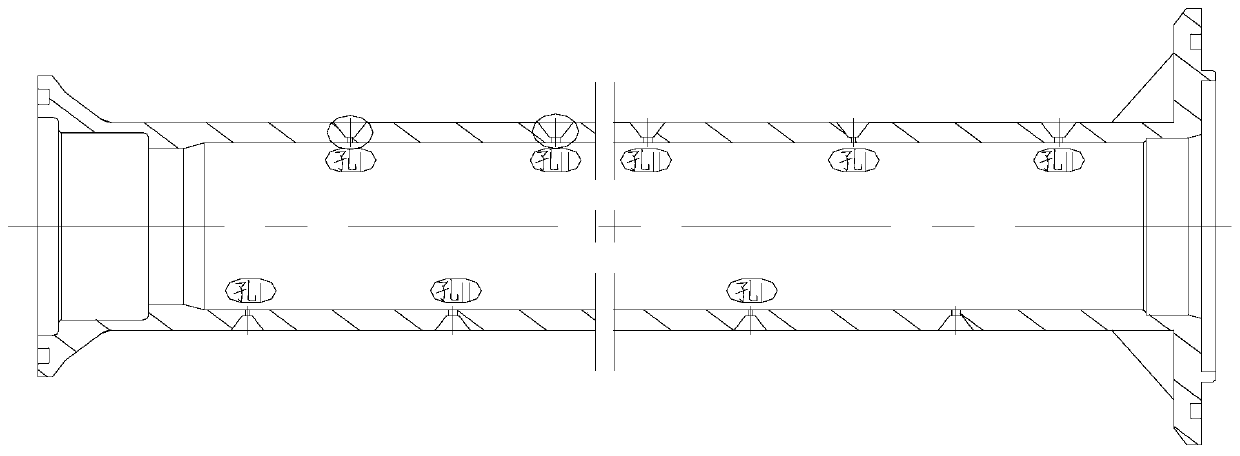

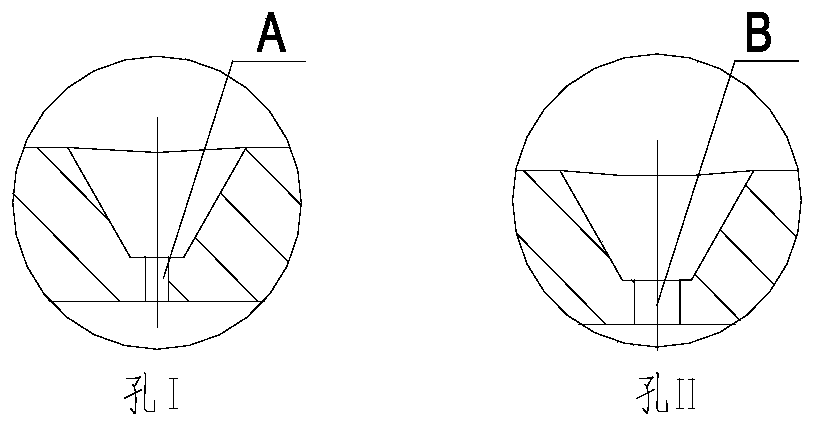

[0025] as attached figure 1 As shown, the present invention provides a single rotary combined gas explosion sound source, including a servo motor 1, a rotor 2, a stator 3, a piston 4, a switch solenoid valve I5, a piston cylinder 6, an air intake joint 7, a switch solenoid Valve II8, Clamp I9, Shaft Sleeve 10, Clamp II11, Deep Groove Ball Bearing 12, Seal Housing I13, Thrust Spherical Roller Bearing 14, Clamp III15, Seal Housing II16, etc. Among them, the servo motor 1 is fixed in the sealed casing II 16, and its output shaft is connected with the shaft hole on the rotor 2 through a flat key. Thrust self-aligning roller bearings 14 and deep groove ball bearings are arranged between the left and right ends of the rotor 2 and the stator 3. The bearing 12 is used as a support, and the cavity part with holes of the rotor 2 is inserted into the casing of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com