Novel all-liquid floating disc and implementation method thereof

An implementation method and floating plate technology, applied in the field of oil storage tank sealing, can solve the problems of inability to use a steel floating plate, poor corrosion resistance, impact on the tank wall, etc., to achieve good overall strength consistency, uniform overall strength, guarantee The effect of overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

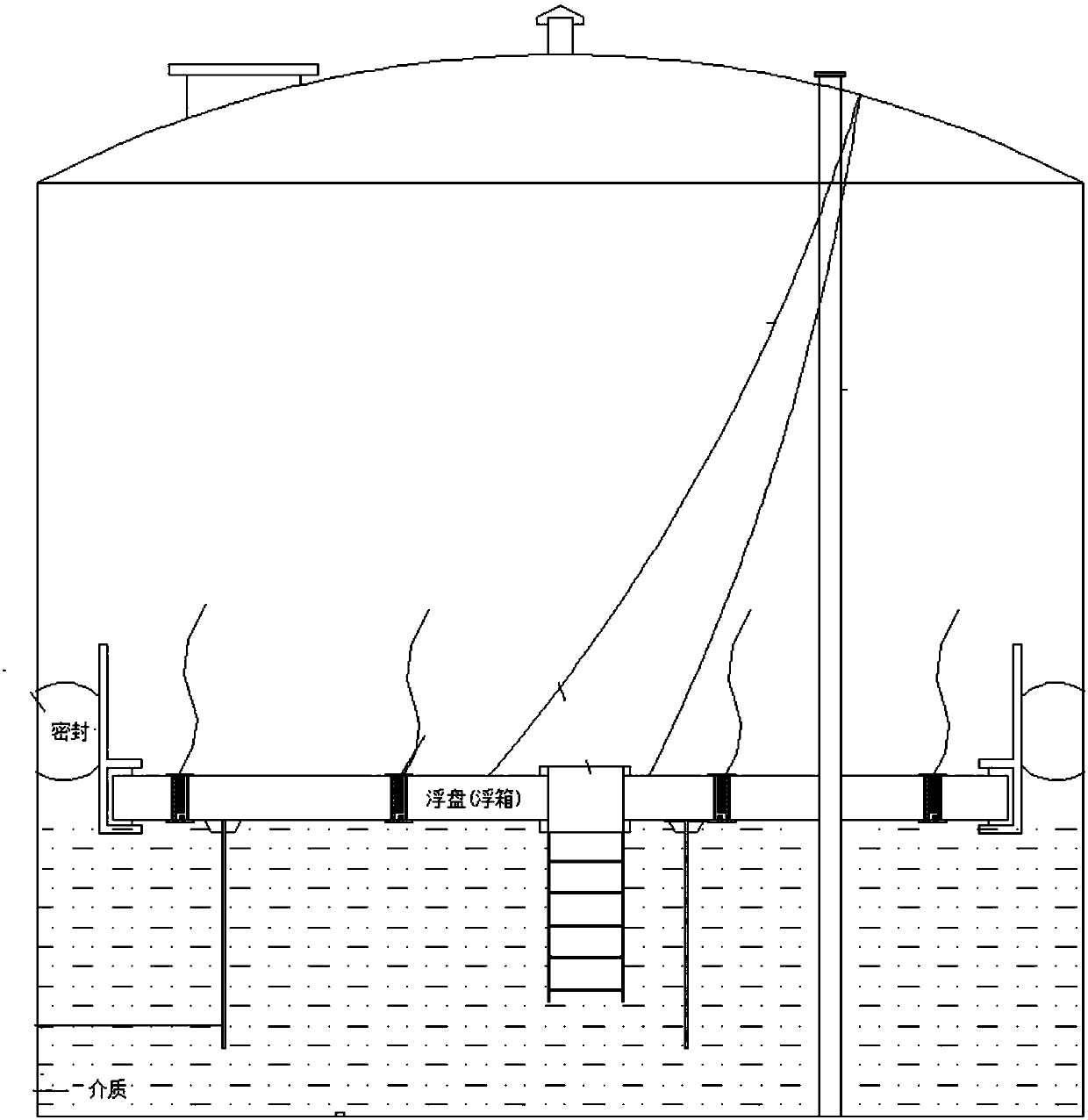

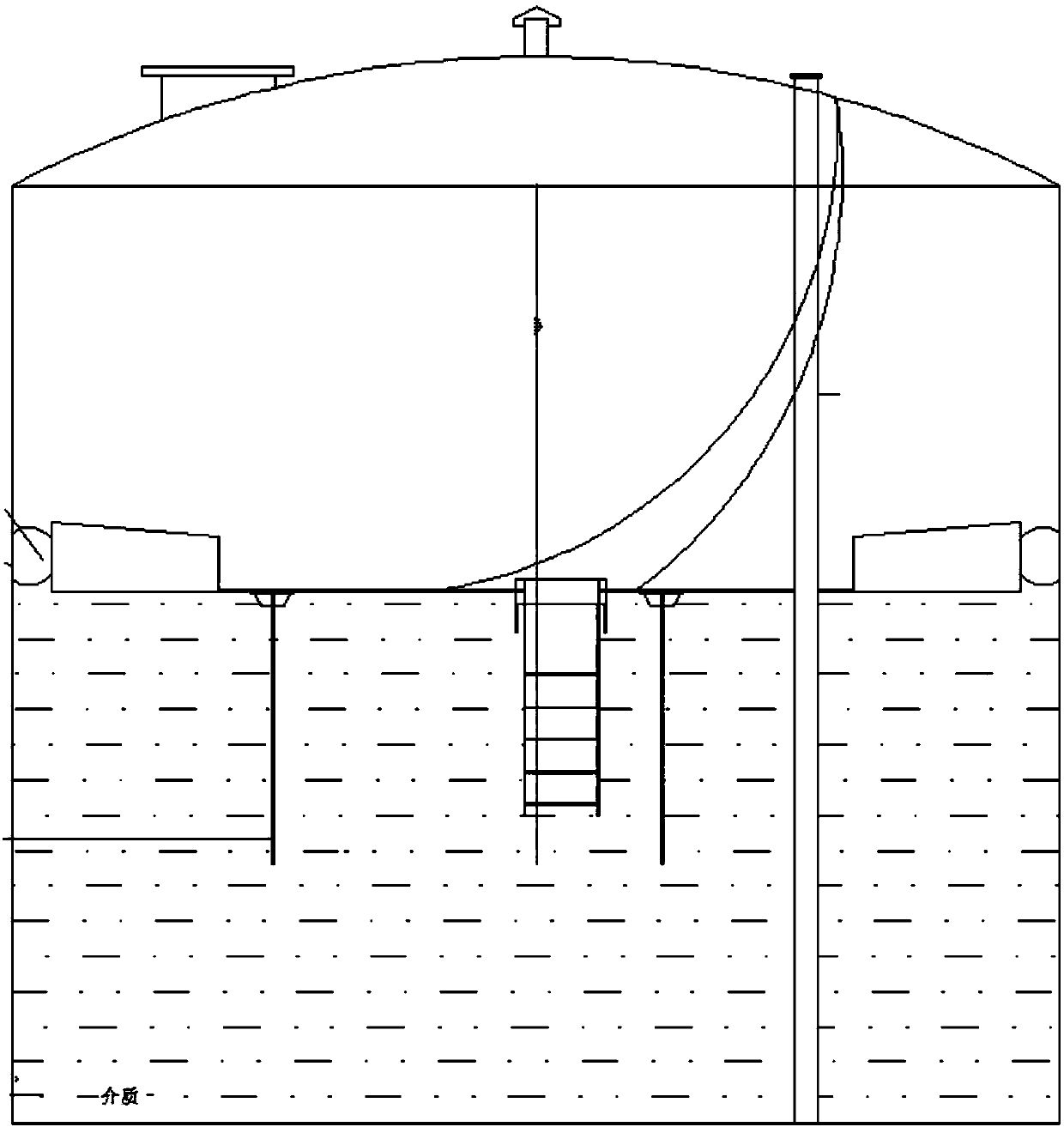

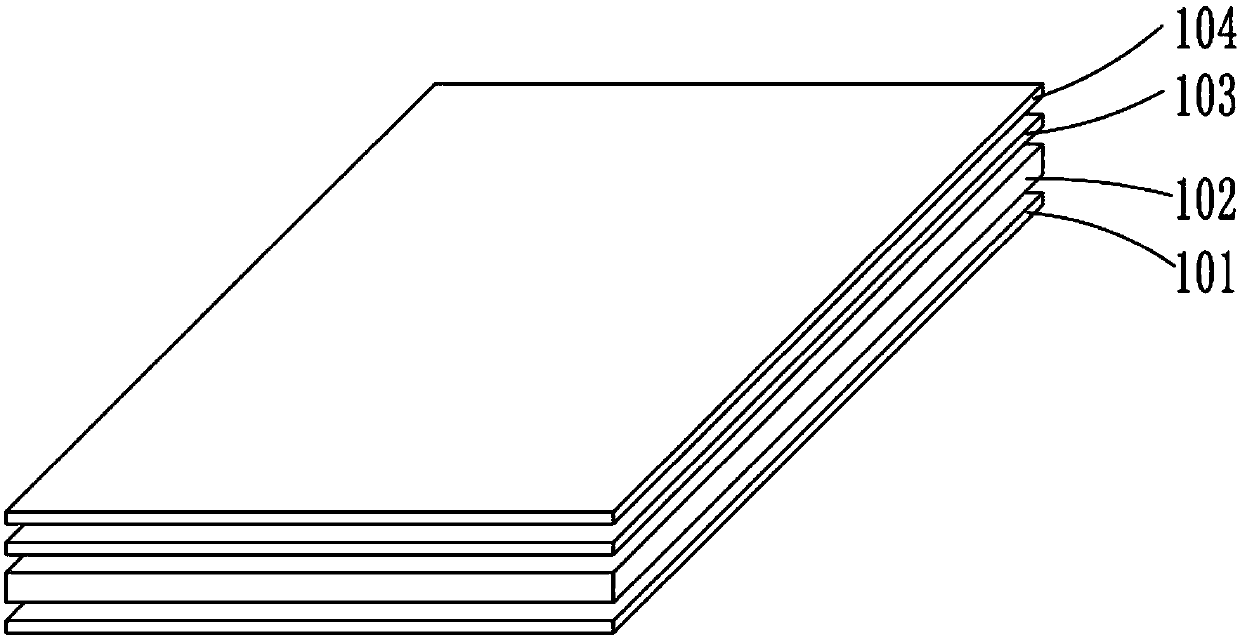

[0048] Figure 4 It is a structural diagram of a new type of fully wetted floating plate provided by the present invention; image 3 It is an exploded structure diagram of each layer of the novel full liquid contact floating plate provided by the invention; Figure 4 , image 3 , the embodiment of the present invention provides a new type of fully liquid-contact floating plate, including a main body of the floating plate immersed in and suspended on the liquid surface, the main body of the floating plate is a composite multi-layer structure composed of different materials, and the multi-layer structure includes:

[0049] The bottom composite layer 101 is the first layer structure which is conductive, corrosion-resistant and reaches a predetermined strength formed by compounding on-site static conductive material, glass fiber reinforced plastic and high-strength resin in the storage tank;

[0050] The intermediate support layer 102 overlaps and covers the top of the bottom co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com