Water-based scratch-resistant ink for plastic films and production process of water-based scratch-resistant ink

A plastic film and water-based technology, which is applied in the field of water-based gravure coating inks, can solve the problems of UV scratch-resistant coatings with strong odor, solvent-based coatings with poor scratch resistance, and potential safety hazards, and achieve the effect of solving the smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

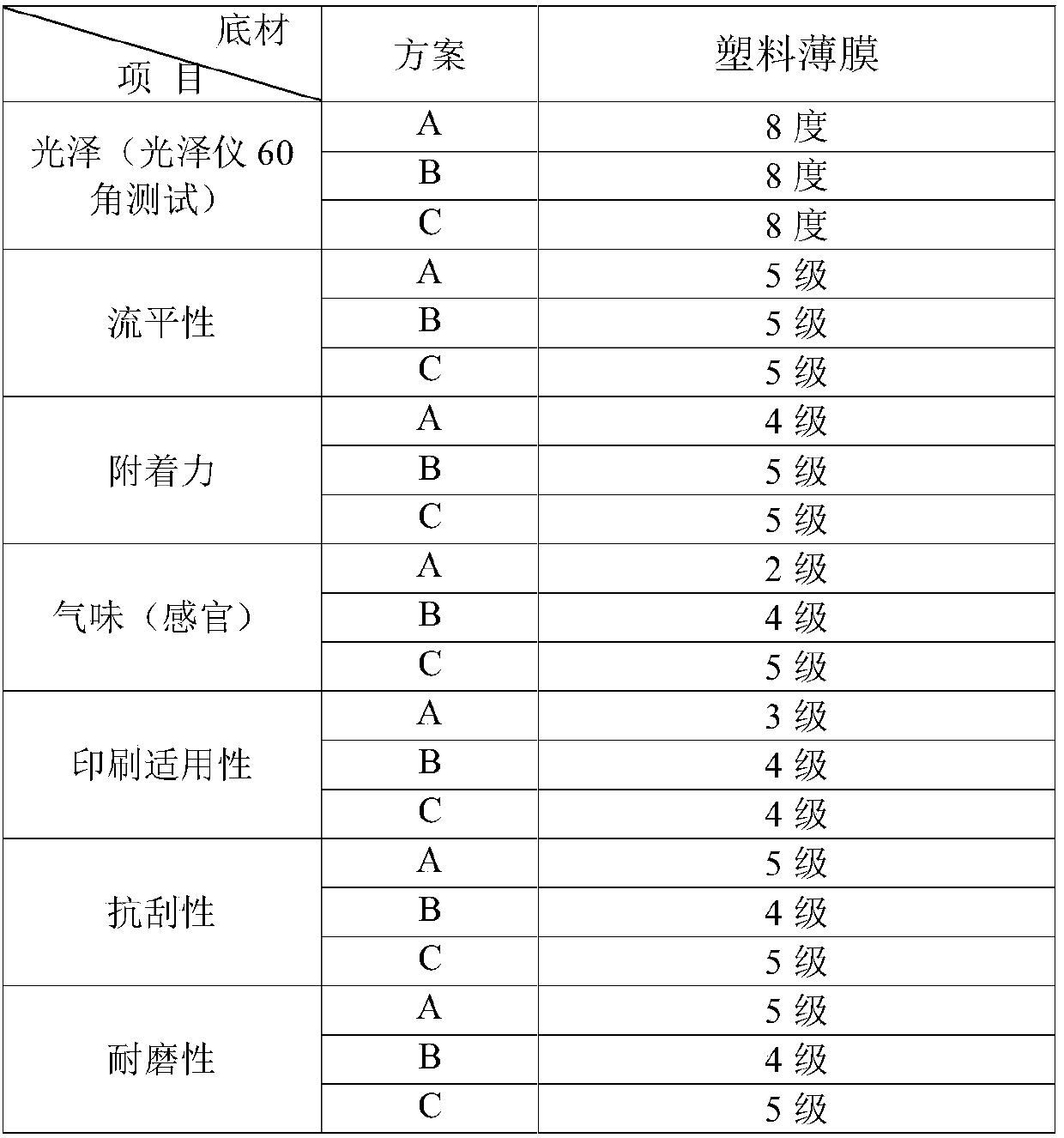

Examples

Embodiment 1

[0087] Embodiment 1: a kind of water-based anti-scratch ink for plastic film of the present invention, by mass percentage, comprises the raw material of following five parts:

[0088] Part A:

[0089] Water-based matting polyurethane PU980 10%;

[0090] Water-based matting polyurethane PU940 20%;

[0091] Water-based bright polyurethane PU77 50%;

[0092] Part B:

[0093] Water-based defoamer TEGO 1488 0.2%;

[0094] Water-based defoamer DF7072 0.2%;

[0095] Part C:

[0096] Water-based coalescent 5%;

[0097] Purified water A 3%;

[0098] Part D:

[0099] Water-based thickener RHEOLATE 288 0.1%;

[0100] Water-based wax paste W-2335A 2%;

[0101] Water-based leveling agent DAPRO-77 1%;

[0102] Water-based wetting agent Surfynol420 1%;

[0103] Water-based pH adjustment liquid DMA 0.5%;

[0104] Water-based cross-linking agent XL-725 4%;

[0105] Part E:

[0106] Purified water B 3%.

Embodiment 2

[0107] Embodiment 2: a kind of water-based anti-scratch ink for plastic film of the present invention, by mass percentage, comprises the raw material of following five parts:

[0108] Part A:

[0109] Water-based matting polyurethane PU980 22.6%;

[0110] Water-based matting polyurethane PU940 30%;

[0111] Water-based bright polyurethane PU77 30%;

[0112] Part B:

[0113] Water-based defoamer TEGO 1488 0.5%;

[0114] Water-based defoamer DF7072 0.5%;

[0115] Part C:

[0116] Water-based coalescent 5%;

[0117] Purified water A 2%;

[0118] Part D:

[0119] Water-based thickener RHEOLATE 288 0.2%;

[0120] Water-based wax paste W-2335A 2%;

[0121] Water-based leveling agent DAPRO-77 0.5%;

[0122] Water-based wetting agent Surfynol420 0.5%;

[0123] Water-based pH adjustment liquid DMA 0.2%;

[0124] Water-based cross-linking agent XL-725 4%;

[0125] Part E:

[0126] Purified water B 2%.

Embodiment 3

[0127] Embodiment 3: a kind of water-based anti-scratch ink for plastic film of the present invention, by mass percentage, comprises the raw material of following five parts:

[0128] Part A:

[0129] Water-based matting polyurethane PU980 40%;

[0130] Water-based matting polyurethane PU940 20%;

[0131] Water-based bright polyurethane PU77 26%;

[0132] Part B:

[0133] Water-based defoamer TEGO 1488 0.5%;

[0134] Water-based defoamer DF7072 0.5%;

[0135] Part C:

[0136] Water-based coalescent 3%;

[0137] Purified water A 2%;

[0138] Part D:

[0139] Water-based thickener RHEOLATE 288 0.5%;

[0140] Water-based wax paste W-2335A 1%;

[0141] Water-based leveling agent DAPRO-77 0.6%;

[0142] Water-based wetting agent Surfynol420 0.6%;

[0143] Water-based pH adjustment liquid DMA 0.3%;

[0144] Water-based crosslinking agent XL-725 3%;

[0145] Part E:

[0146] Purified water B 2%.

[0147] A kind of production technology of the water-based anti-scratch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com