Inclined flap check valve

A check valve and oblique flap technology, applied in the field of oblique flap check valves, can solve problems such as pressure loss and inapplicability, and achieve the effect of reducing difficulty and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

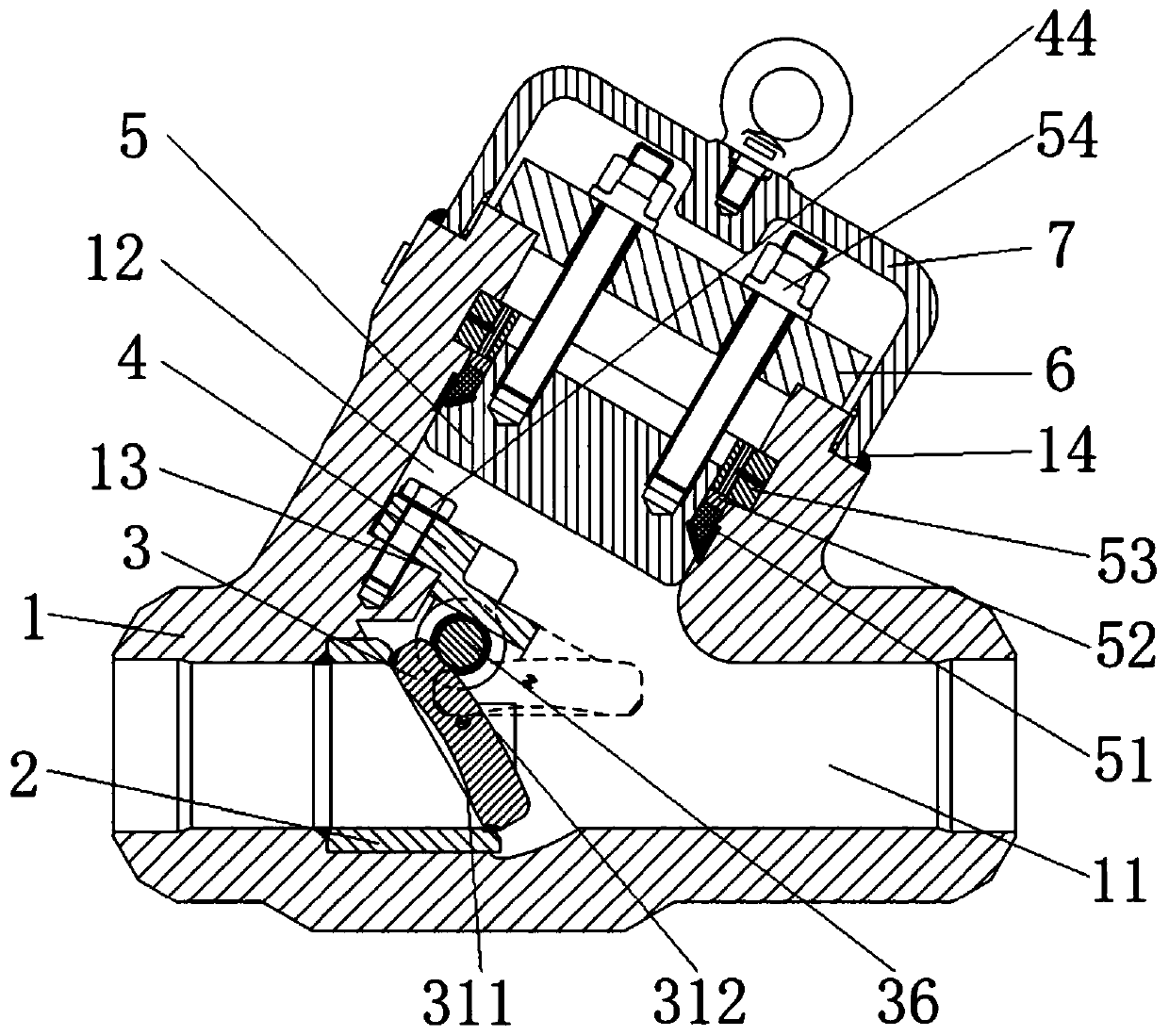

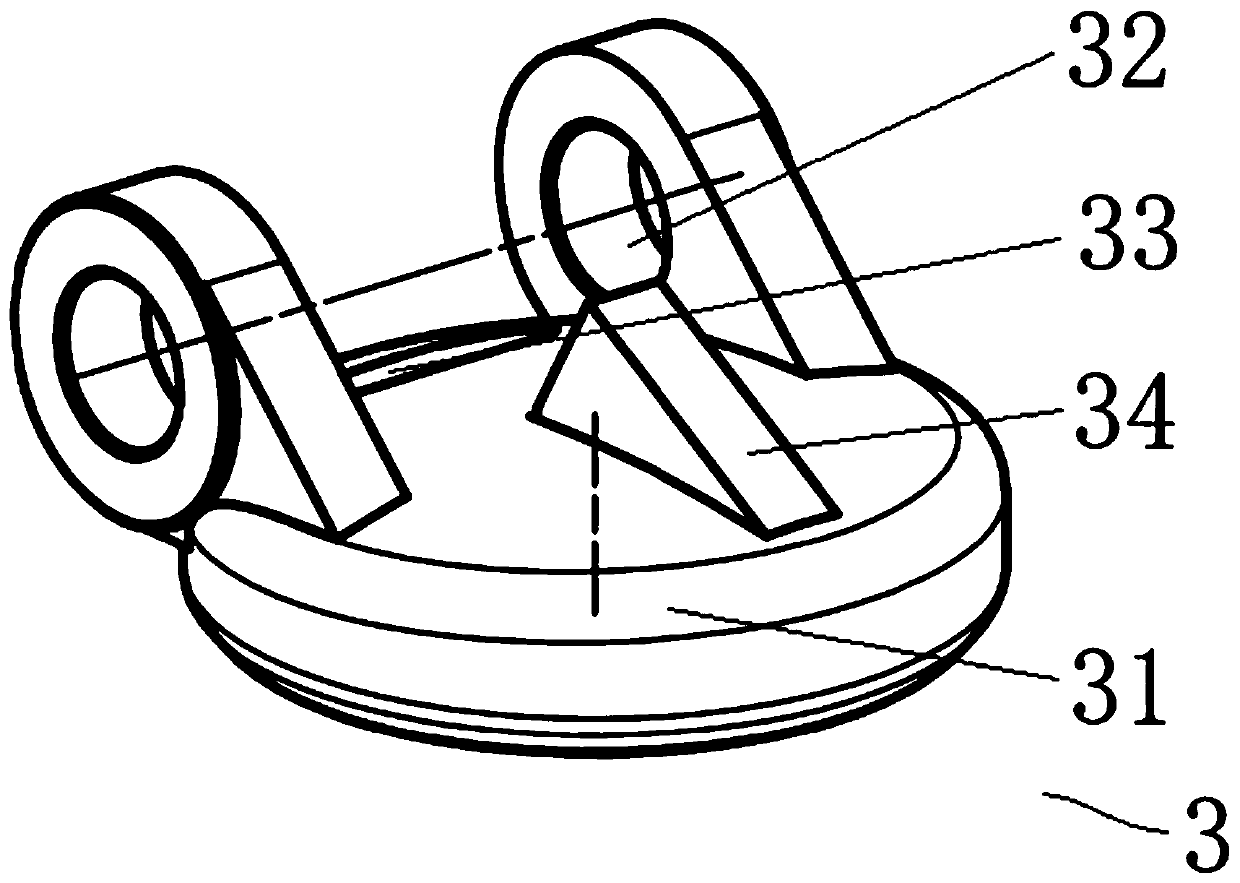

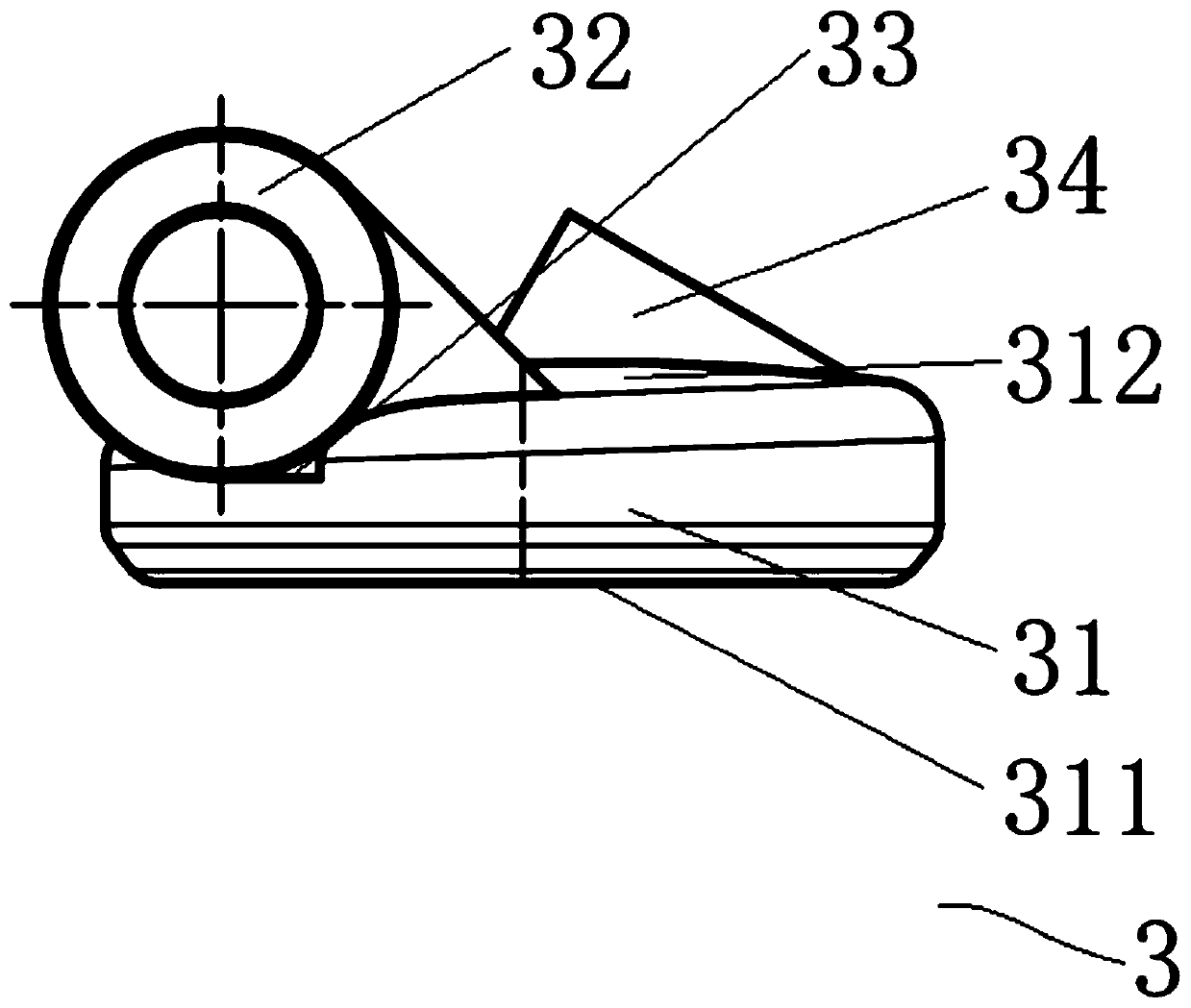

[0045] Such as Figure 1 to Figure 4 A kind of oblique disc check valve is shown, which includes a valve body 1, a valve seat 2 and a valve disc 3; wherein a valve cavity 12 and a medium channel 11 are formed in the valve body 1, and the valve seat 2 can be fixed by, for example, welding Sleeved in the medium channel 11, and the inner surface of the valve seat 2 does not protrude from the inner surface of the medium channel 11 and is set in the medium channel; the valve disc 3 is set at the intersection of the installation valve cavity 12 and the medium channel 11; the installation valve cavity 12 is set at an angle to the medium channel 11; the valve cover 5, the installation boss 13 and the connector 4 are all arranged in the installation valve chamber 12, and the support connector 6 and the sealing protective cover 7 are arranged at the end of the installation valve chamber 12.

[0046] By setting the inner surface of the valve seat 2 in the valve body without protruding fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com