Gas sealing property simulation comprehensive detection system

A technology of gas sealing and simulation synthesis, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of inaccurate test results, accelerated test methods, single measurement objects, etc., to reduce experimental test time and improve work Efficiency, the effect of saving enterprise cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

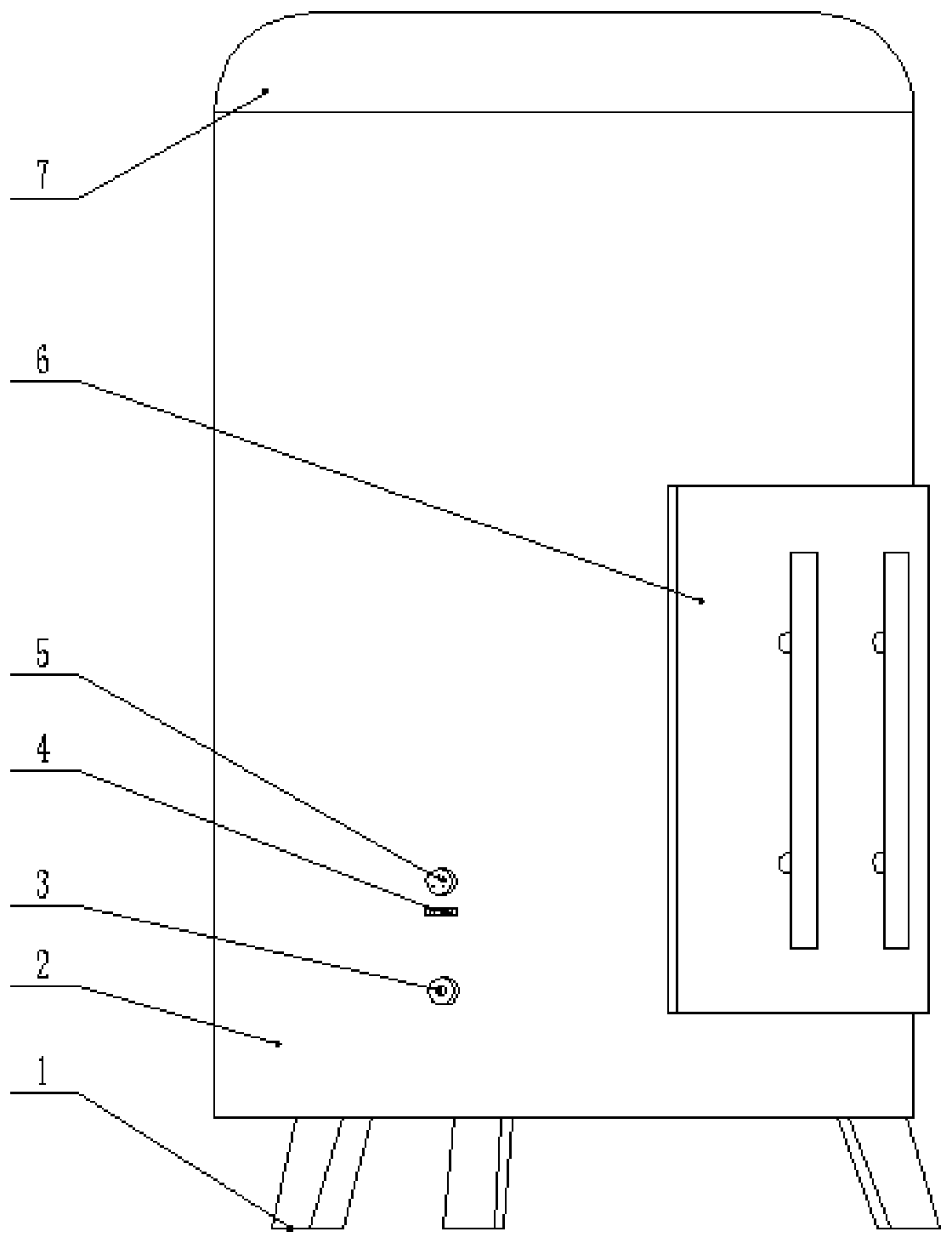

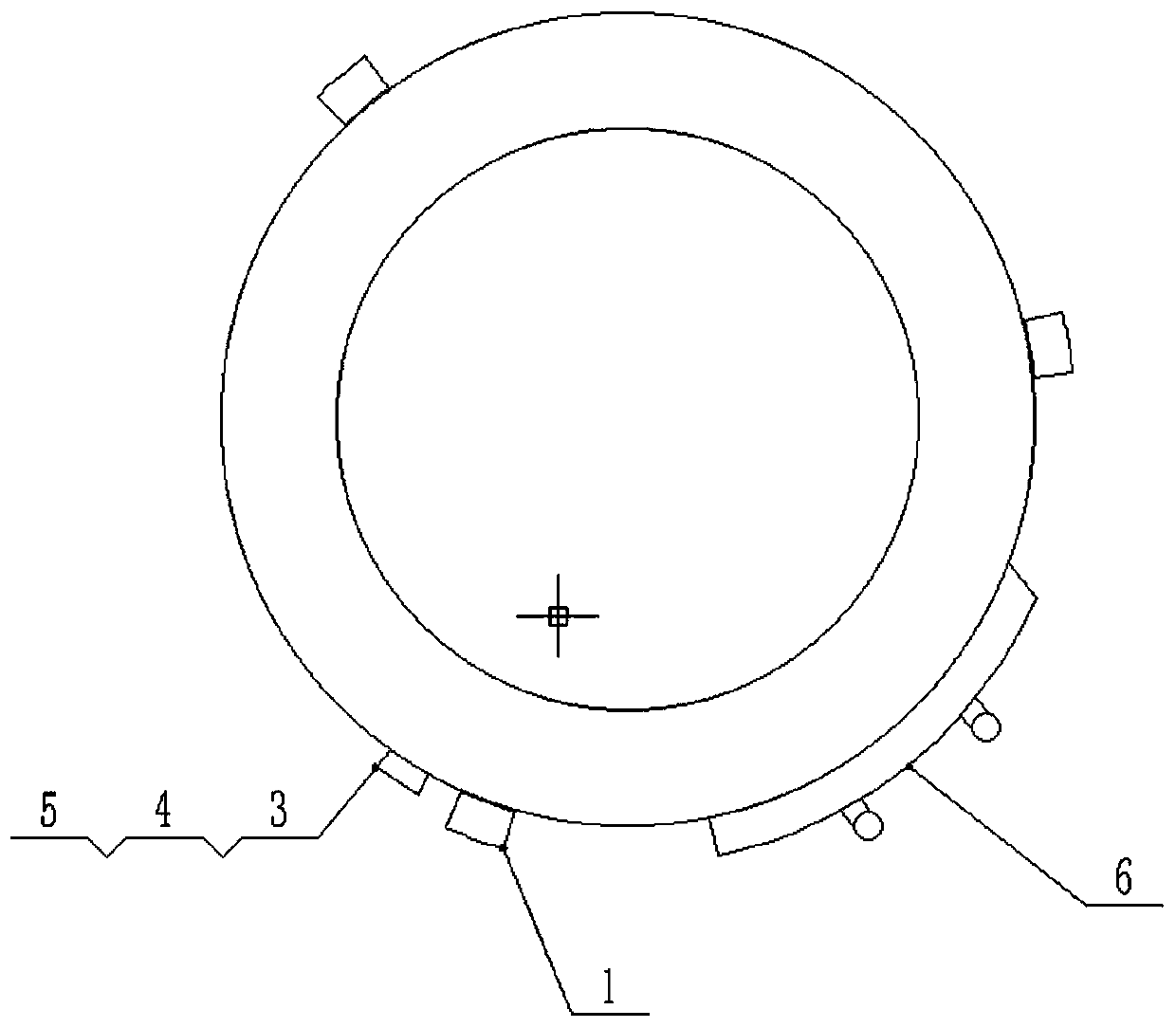

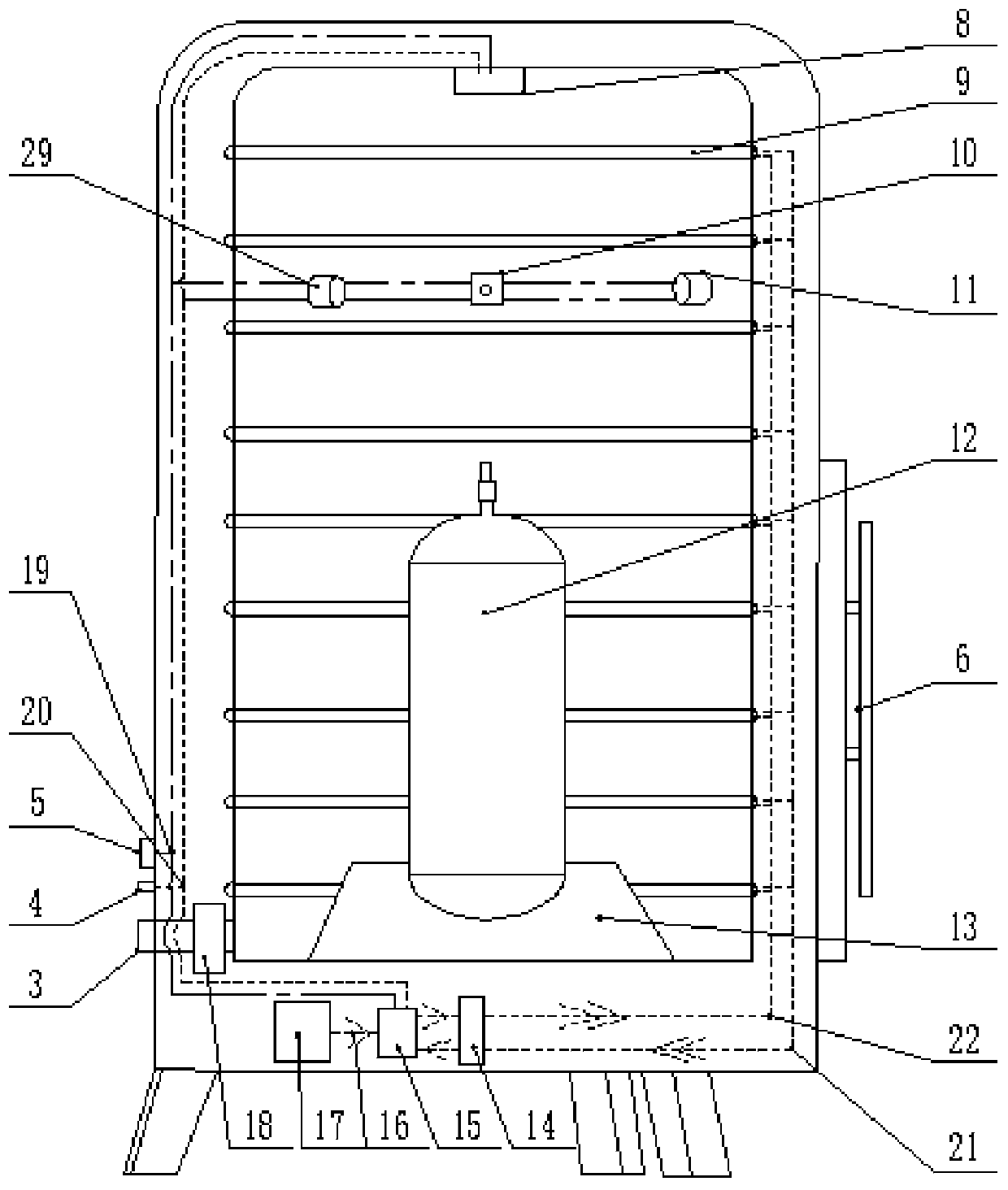

[0026] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

[0027] Aiming at the phenomenon that the detection cycle is long and it is not easy to monitor for a long time in the current field of gas sealing element sealing performance detection, the present invention proposes a gas sealing performance comprehensive detection system based on various accelerated test methods, so as to realize the rapid detection of the gas sealing performance of the gas sealing element Detection, reduce test cycle, reduce test cost purpose. Such as Figure 1-4 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com