On-line monitoring and fault diagnosis method of motor based on "correct tree" model

A fault diagnosis, correct technique, applied in motor generator testing, mechanical component testing, machine/structural component testing, etc., that can solve the problem of high professional knowledge and experience requirements, complex data acquisition hardware, and inability to explicitly model and other problems, to achieve the effect of low cost, wide application range and reduced application difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

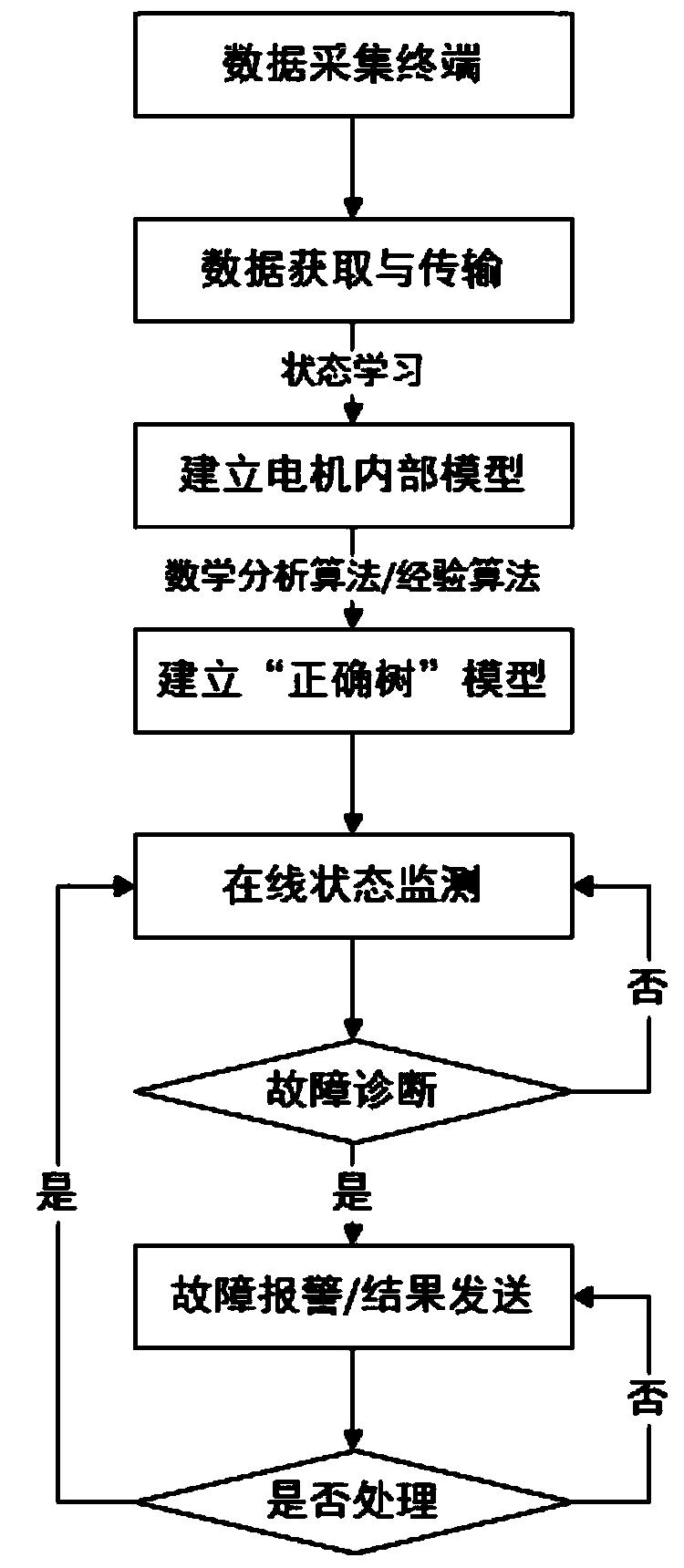

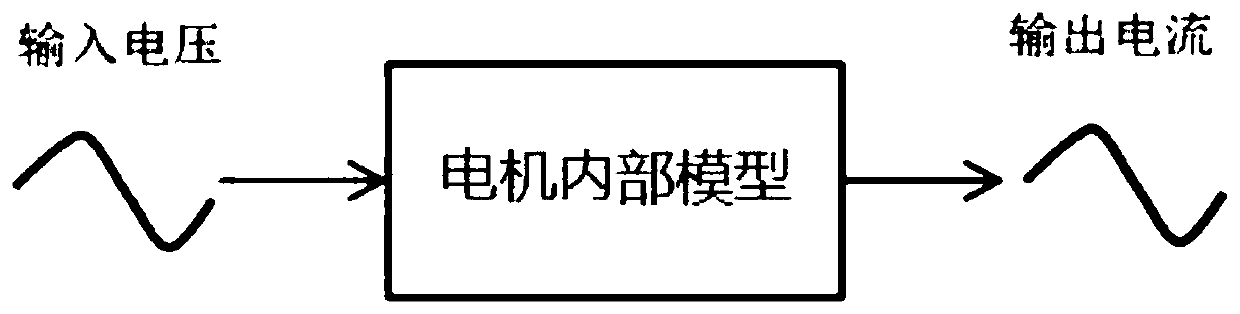

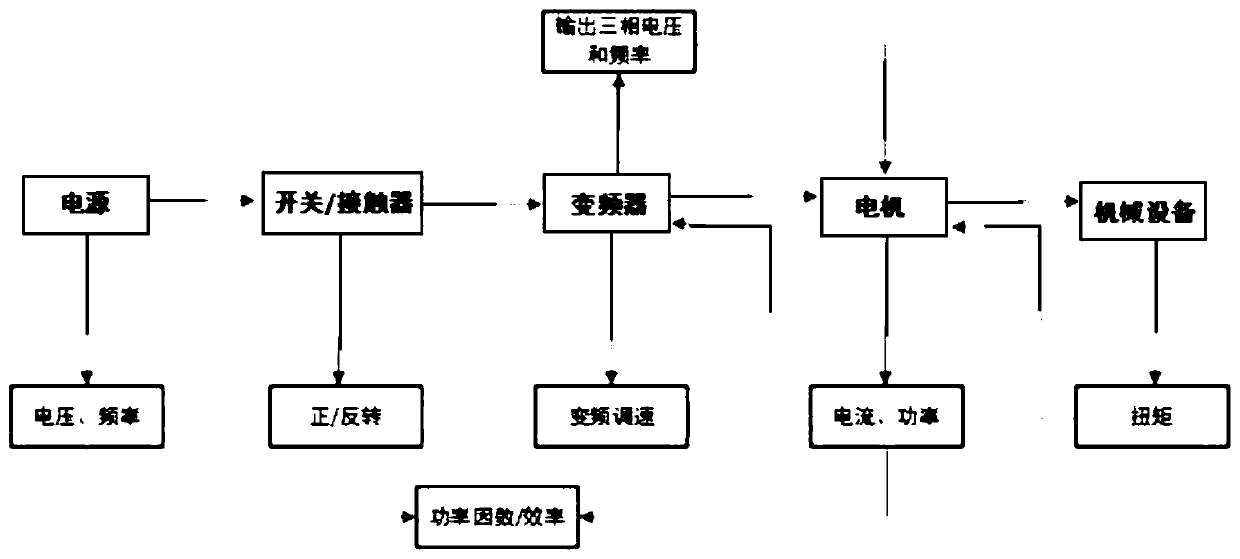

[0050] see Figure 1-Figure 4 , the present invention is based on the "correct tree" model of the motor on-line monitoring and fault diagnosis method, which is a system composed of software and networked hardware. The data acquisition terminal of the system can generally be placed in the control cabinet of the motor to measure the phase voltage and phase current waveform data of the motor online in real time. According to the measurement results, it takes a certain amount of time (generally no more than 8 days) to learn the motor operation mode , using machine learning algorithms to establish a "correct tree" model of the normal operating conditions of the motor to identify and save the normal operating conditions of the equipment. After the model is normally established and optimized, it starts to monitor the operating conditions of the motor. Once the operating condition exceeds the normal condition, the system can issue a warning and confirm whether it is a fault or a new ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com