Continuous flow centrifuge rotor device and centrifuge

A centrifuge rotor and rotor technology, applied in the field of centrifugation, can solve the problems of insufficient rotational speed centrifugal force, affecting centrifugal efficiency, and simultaneous operation, and achieve the effects of large rotational speed and relative centrifugal force, good centrifugal effect, and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more obvious and understandable, the detailed description is as follows in conjunction with the accompanying drawings.

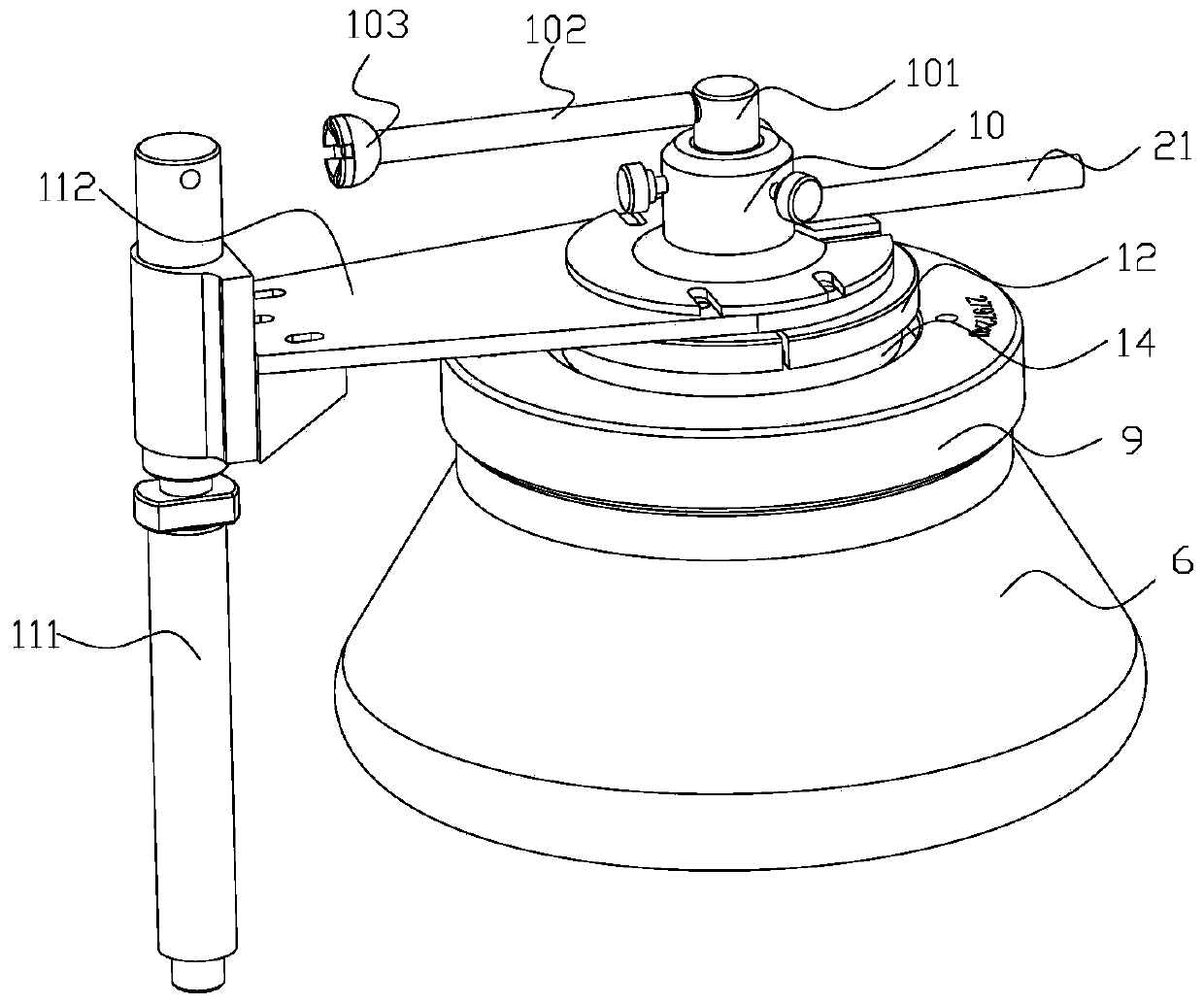

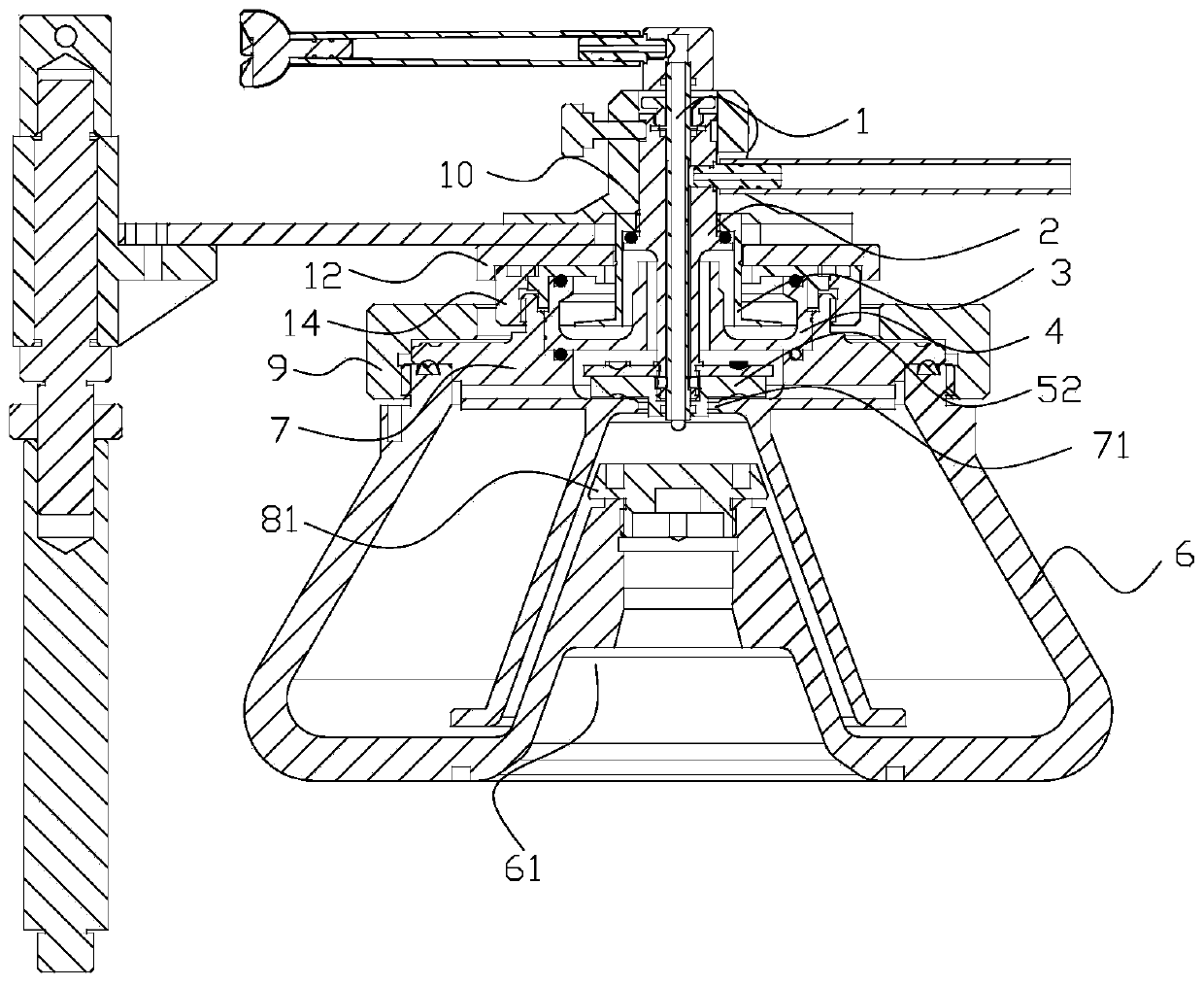

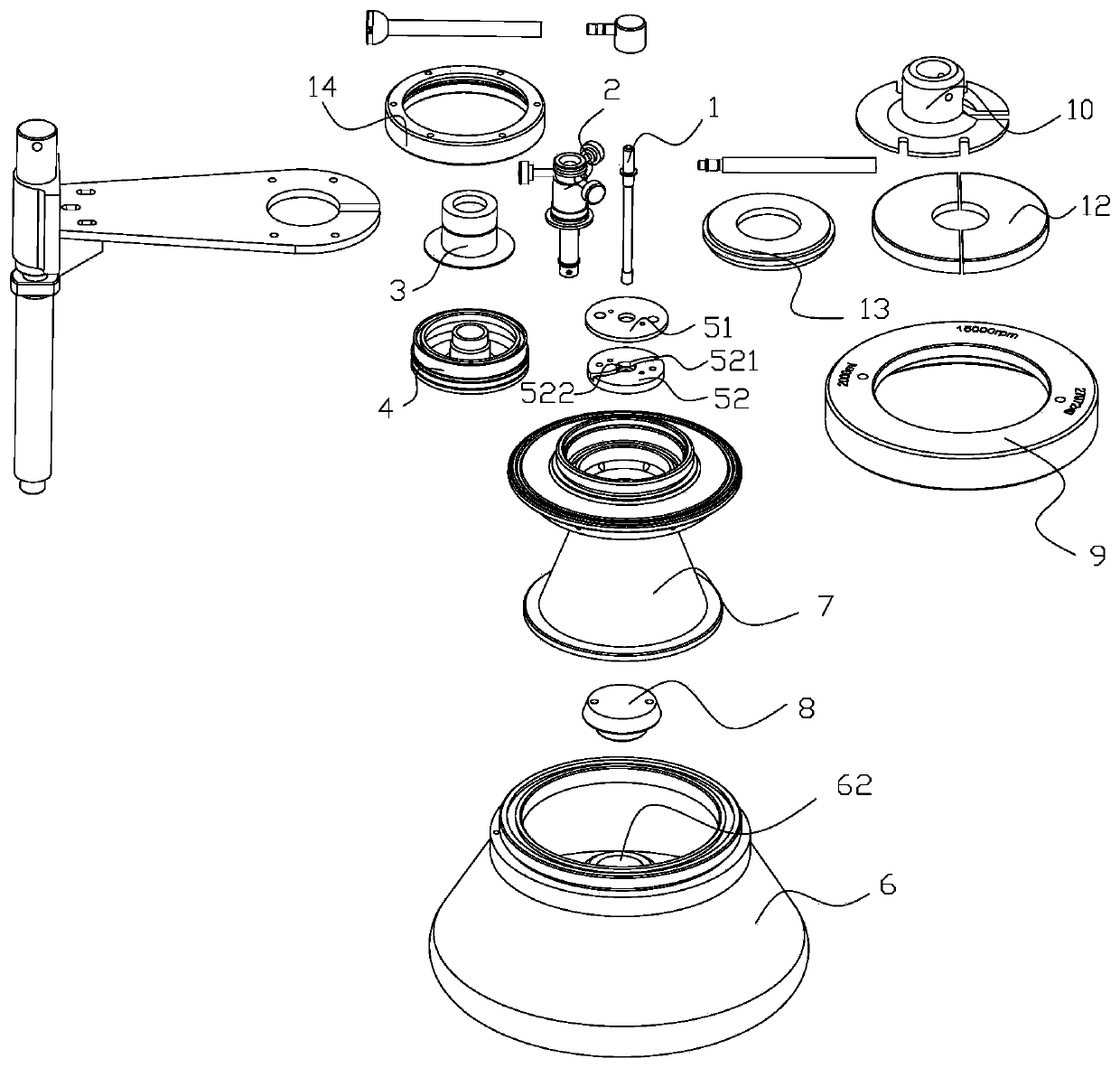

[0025] Such as Figure 1 to Figure 4 Shown, a kind of aseptic continuous flow centrifuge, this centrifuge comprises centrifugal motor rotating shaft and centrifuge rotor device; Centrifuge rotor device is arranged on the centrifugal motor rotating shaft; 2. Spacer sleeve 3, sealing cover 4, centripetal pump assembly, rotor body 6, rotor core 7, transmission pin mounting block 8 and rotor cover 9. The drain pipe seat 2 is sleeved on the sampling tube 1 , and the sampling tube 1 is connected with a sampling connecting tube 102 through a sampling sealing seat 101 . The feeding end of the sampling connection pipe 102 is connected with a sampling tube weight 103 . A plurality of drain holes are arranged around the bottom of the drain socket 2 , and a liquid outlet connecting pipe 21 is arranged on the top of the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com