Five-axis numerical control machine tool space error detecting method based on rotation tool center point (RTCP)

A technology of spatial error and detection method, applied in measurement/indication equipment, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of complex detection process, high detection cost, time-consuming, etc., to simplify the detection process and improve detection. Efficiency, the effect of reducing inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

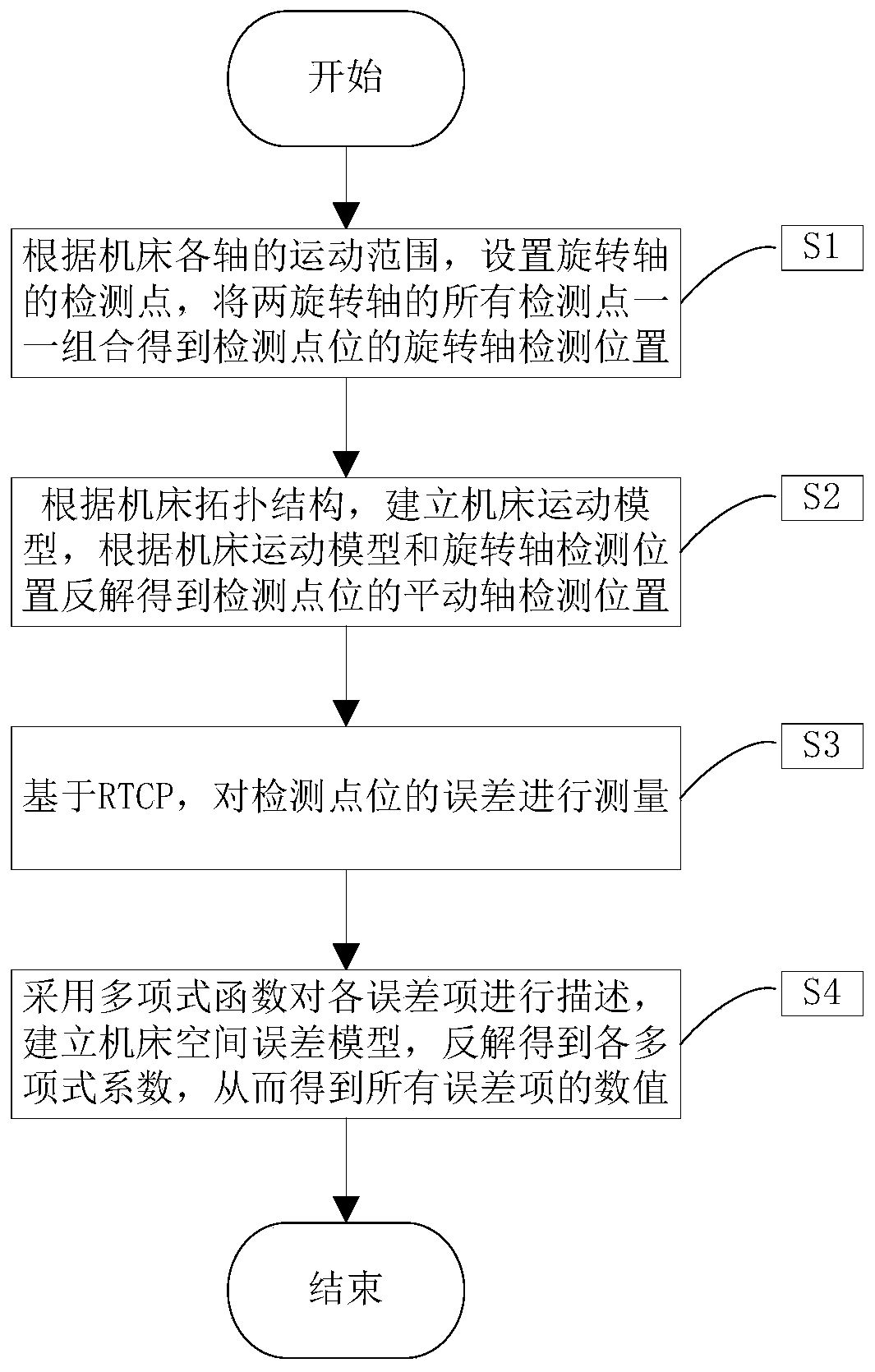

[0042] see figure 1 , the present invention proposes a five-axis CNC machine tool space error detection method based on RTCP, which is realized by the following steps:

[0043] S1. According to the movement range of each axis of the machine tool, set the detection points of the two rotation axes, and combine all the detection points of the two rotation axes one by one to obtain the detection position of the rotation axis of the detection point.

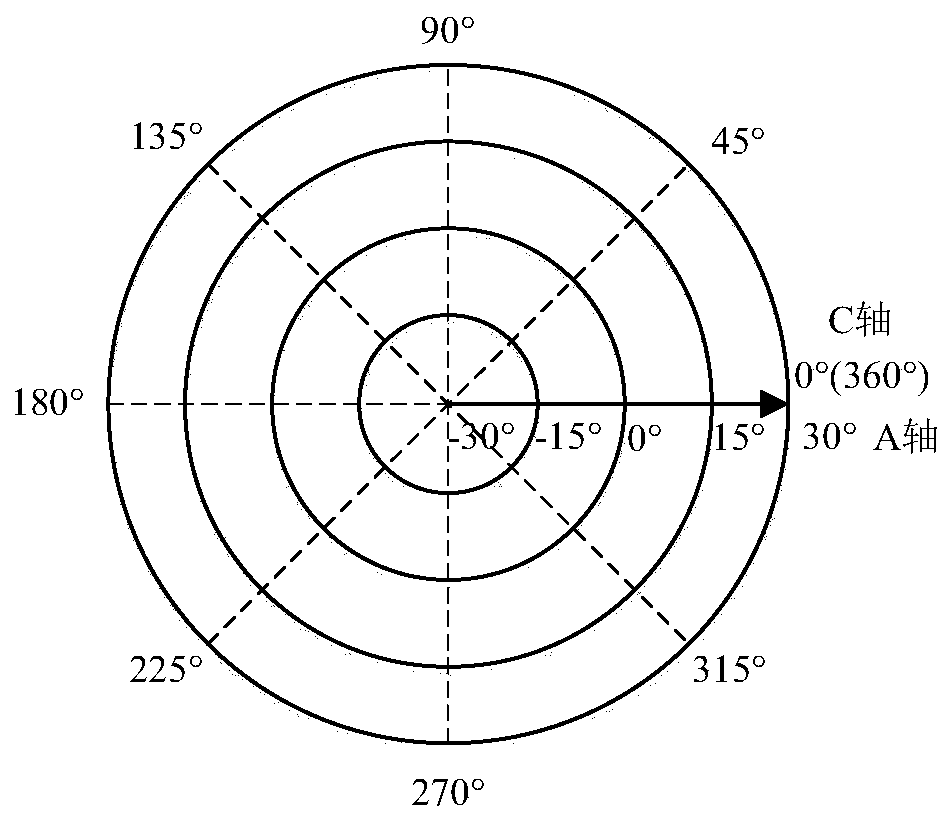

[0044] In this embodiment, according to the range of motion of each axis of the machine tool, the detection numbers of the rotation axes A and C are respectively set, and the detection points of the rotation axes A and C are respectively obtained by dividing the range of motion of each rotation axis according to the detection numbers. , combine all the detection points of the rotation axis A and C one by one to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com