Elevator weight test device and method

A test device and elevator technology, which is applied in the field of elevators, can solve the problems of long test time, high labor intensity, hidden dangers of equipment and personnel safety, etc., and achieve the effects of reducing labor intensity, good stability, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

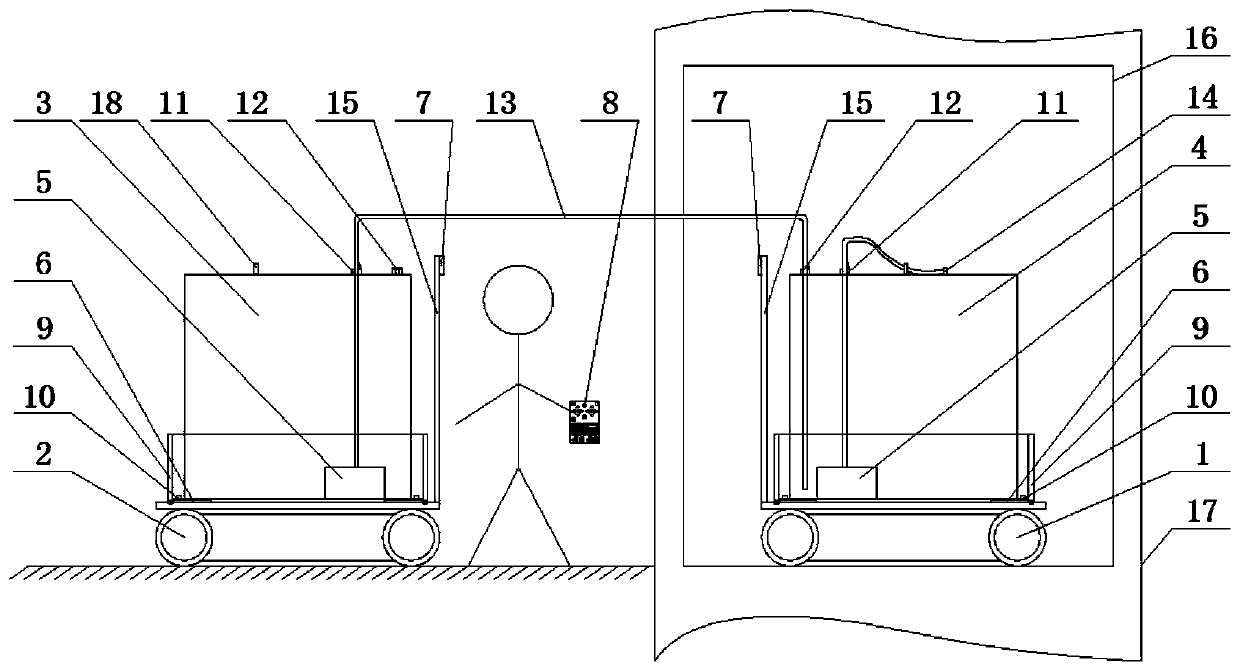

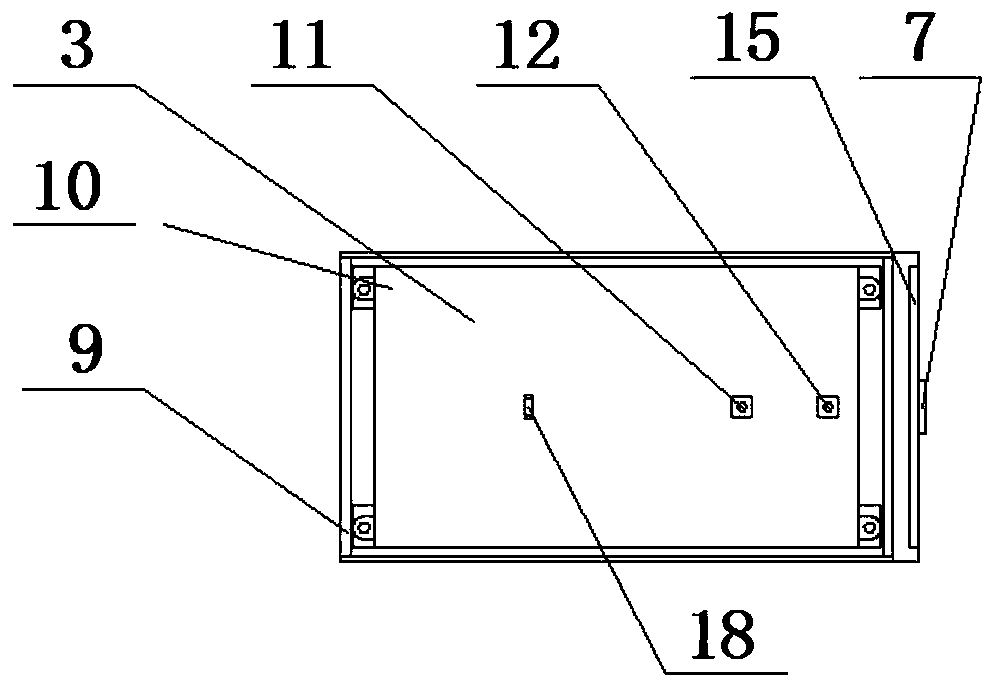

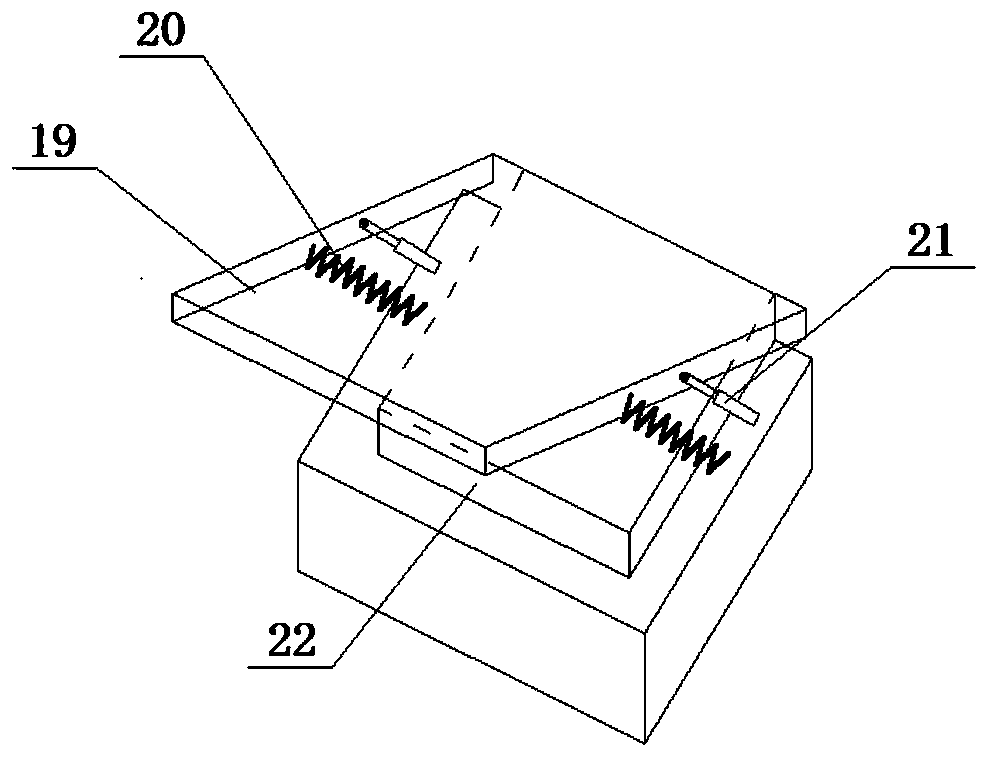

[0049] Such as Figure 1-8 Shown, a kind of elevator weight testing device comprises test trolley 1, control trolley 2, the water storage tank 3 of control trolley, the water tank 4 (being called for short test water tank) of test trolley, water pump 5, Load cell 6, display screen 7 and controller 8.

[0050] The trolley is driven by a motor and plastic tracks, and a load cell 6 is arranged on the trolley, which displays the weight of the vehicle on a display screen 7 near the handrail of the trolley. Through the keyboard on the controller 8, input the rated load capacity, loading factor, the total weight of the test trolley and the test water tank, automatically calculate the volume of water to be added, and transfer from the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com