Glass fiber strand production equipment

A technology for glass fiber and production equipment, applied in the field of new material production equipment, can solve problems such as reducing work efficiency, unable to guarantee the production quality of glass fiber precursors, etc., achieving high production efficiency, humanized production process, and increasing the area for dust removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

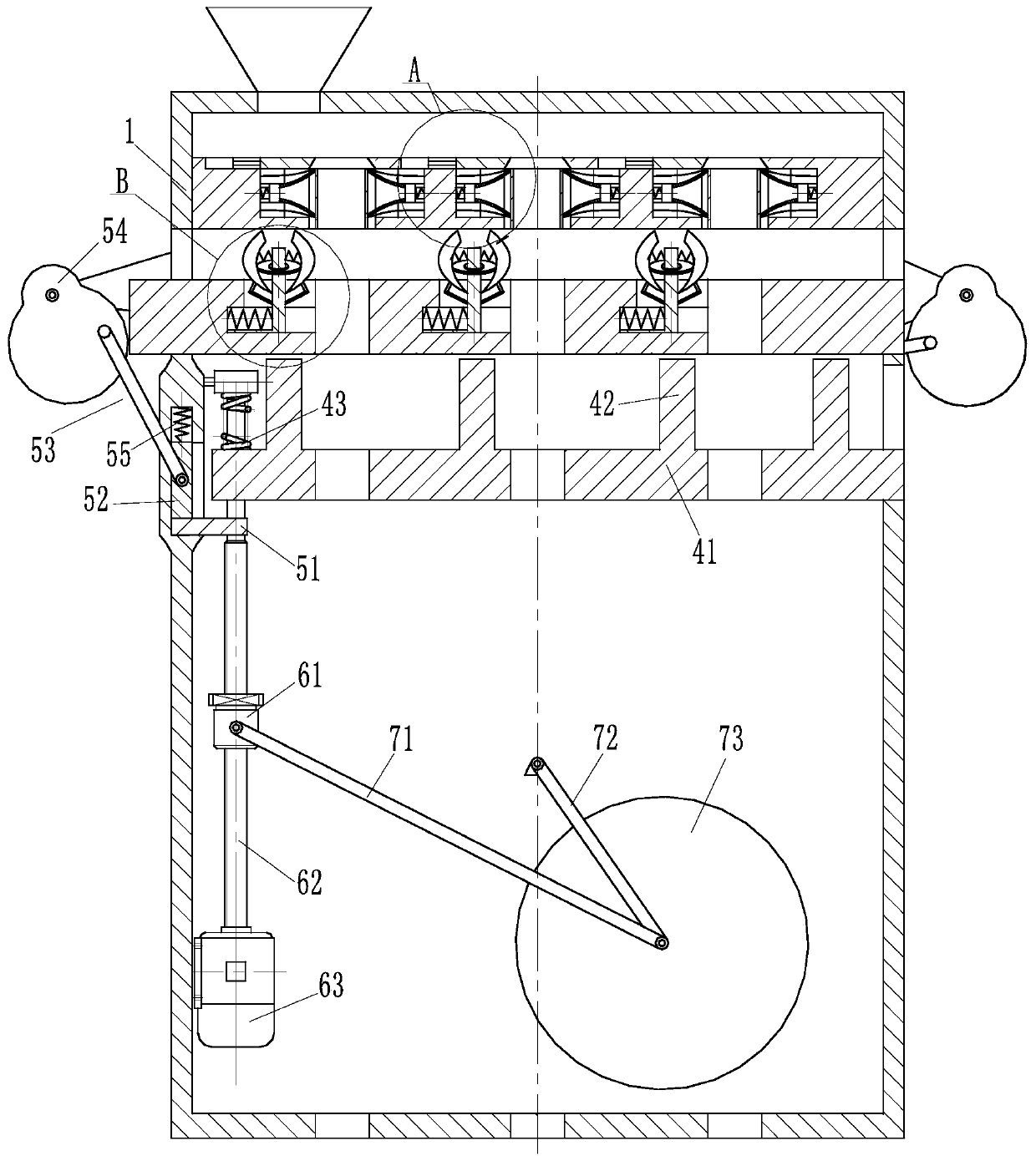

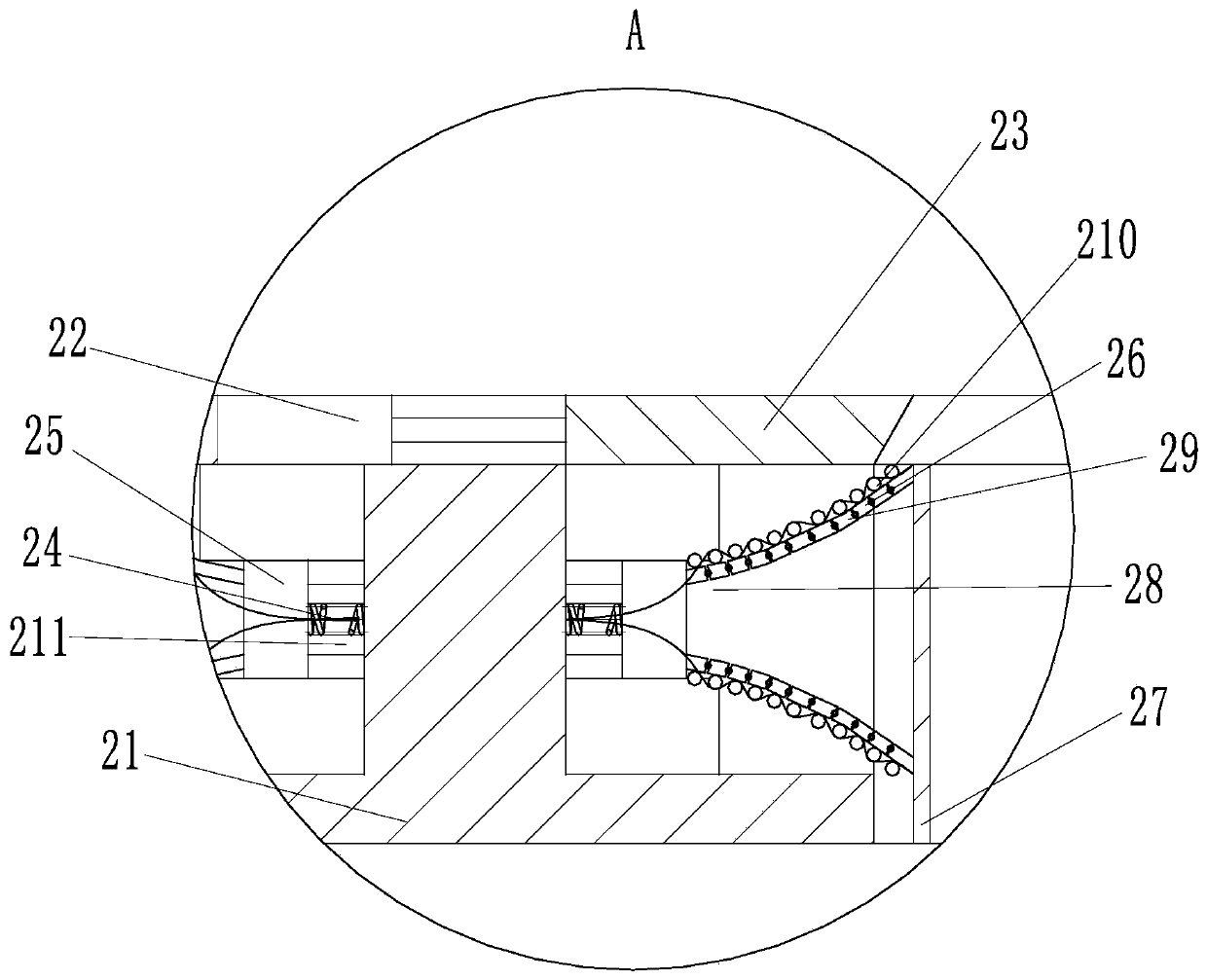

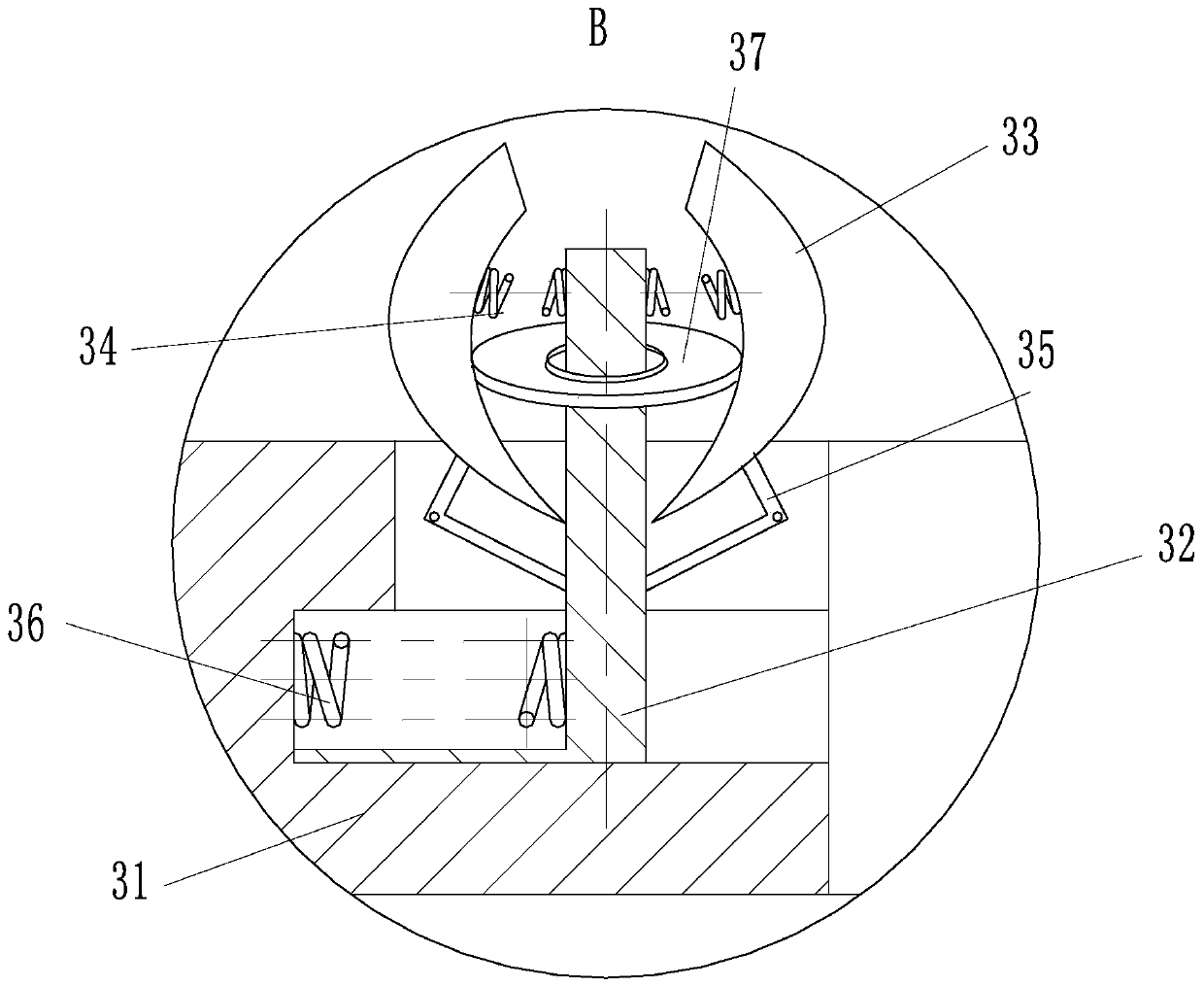

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further elaborate the present invention in conjunction with the specific embodiments. figure 1 as the benchmark.

[0025] Such as Figure 1 to Figure 4 As shown, a kind of glass fiber precursor production equipment described in the present invention includes a housing 1 and a bushing 21, the inner side of the housing 1 is provided with a guide rail and a chute; the bushing 21 is located at the upper end of the housing 1, The leakage plate 21 is fixedly connected with the housing 1, and a leakage hole is arranged in the leakage plate 21; it also includes a dredging plate 31, a dredging rod 32, a dredging flap 33, a No. 1 spring 34, a support rod 35, a top plate 41, a top column 42, two No. spring 43, slide plate 51, slide block 52, push rod 53, cam 54, No. 3 spring 55, nut 61, screw rod 62, motor 63, the dredging plate 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com