Regeneration brick prepared from construction waste and preparation method of brick

A technology for construction waste and recycled bricks, applied in the field of building materials, can solve the problems of low service life, low strength of recycled bricks, waste of construction waste resources, etc., and achieve the effect of improving service life, realizing recycling and reusing, and solving waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

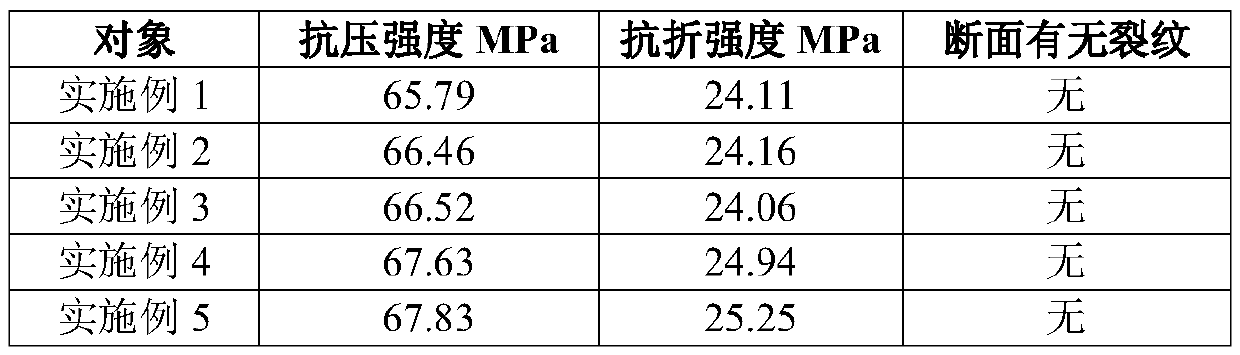

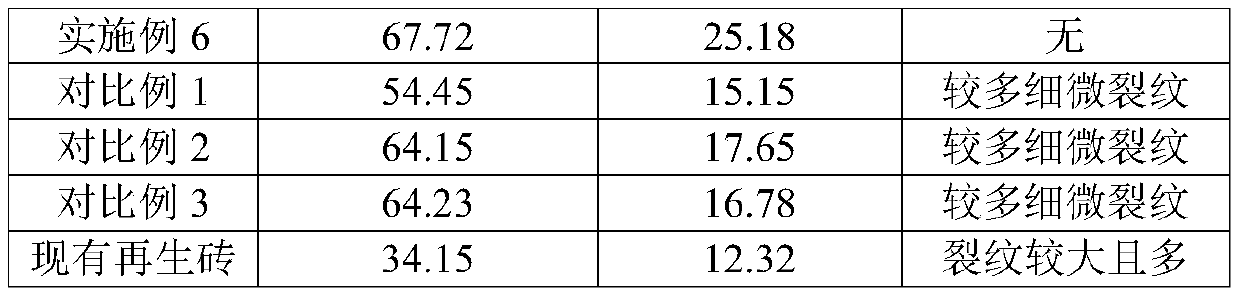

Examples

Embodiment 1

[0029] The regenerated brick of this embodiment is made of the following raw materials: 100 parts by weight of construction waste aggregate, 10 parts of kaolin, 30 parts of fly ash, 1 part of water reducer, 1 part of early strength agent, and 1 part of antifreeze and 15 parts of water; wherein, construction waste aggregates include: 50% of heavy aggregates, 40% of light aggregates and 10% of wood fiber in terms of weight percentage; heavy aggregates include waste concrete, waste bricks and tiles and waste stones, which The mass ratio is 1:0.5:0.5; the lightweight aggregate includes waste ceramics and waste glass, and its mass ratio is 1:0.8.

[0030] The wood fiber of present embodiment is made by following method:

[0031] Step A: After cleaning the waste wood, the papermaking chemical mechanical pulping method is used to prepare the crude fiber;

[0032] Step B: Soak the crude fiber in lye with a concentration of 5wt% at 35°C for 8 hours, the mass ratio of crude fiber to ly...

Embodiment 2

[0037] The regenerated brick of this embodiment is made of the following raw materials: 100 parts by weight of construction waste aggregate, 20 parts of kaolin, 50 parts of fly ash, 5 parts of water reducer, 5 parts of early strength agent, and 5 parts of antifreeze and 25 parts of water; wherein, construction waste aggregate includes: heavy aggregate 60%, light aggregate 32% and wood fiber 8% by weight percentage; heavy aggregate includes waste concrete, waste brick and tile and waste stone, Its mass ratio is 1:1:1; light aggregate includes waste ceramics and waste glass, and its mass ratio is 1:1.2.

[0038] The wood fiber of present embodiment is made by following method:

[0039] Step A: After cleaning the waste wood, the papermaking chemical mechanical pulping method is used to prepare the crude fiber;

[0040] Step B: Soak the crude fiber in lye with a concentration of 10wt% at 25°C for 8h-12h, the mass ratio of crude fiber to lye is 1:40, and the lye is potassium hydro...

Embodiment 3

[0045] The regenerated brick of this embodiment is made of the following raw materials: 100 parts by weight of construction waste aggregate, 15 parts of kaolin, 40 parts of fly ash, 2 parts of water reducer, 2 parts of early strength agent, and 2 parts of antifreeze and 20 parts of water; wherein, construction waste aggregates include: 55% of heavy aggregates, 35% of light aggregates and 10% of wood fiber in terms of weight percentage; heavy aggregates include waste concrete, waste bricks and tiles and waste stones, which The mass ratio is 1:0.8:0.8; the lightweight aggregate includes waste ceramics and waste glass, and its mass ratio is 1:1.

[0046] The wood fiber of present embodiment is made by following method:

[0047] Step A: After cleaning the waste wood, the papermaking chemical mechanical pulping method is used to prepare the crude fiber;

[0048] Step B: Soak the crude fiber in lye with a concentration of 8wt% at 30°C for 10 hours, the mass ratio of crude fiber to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com