A kind of graphene lubricating oil additive and preparation method thereof

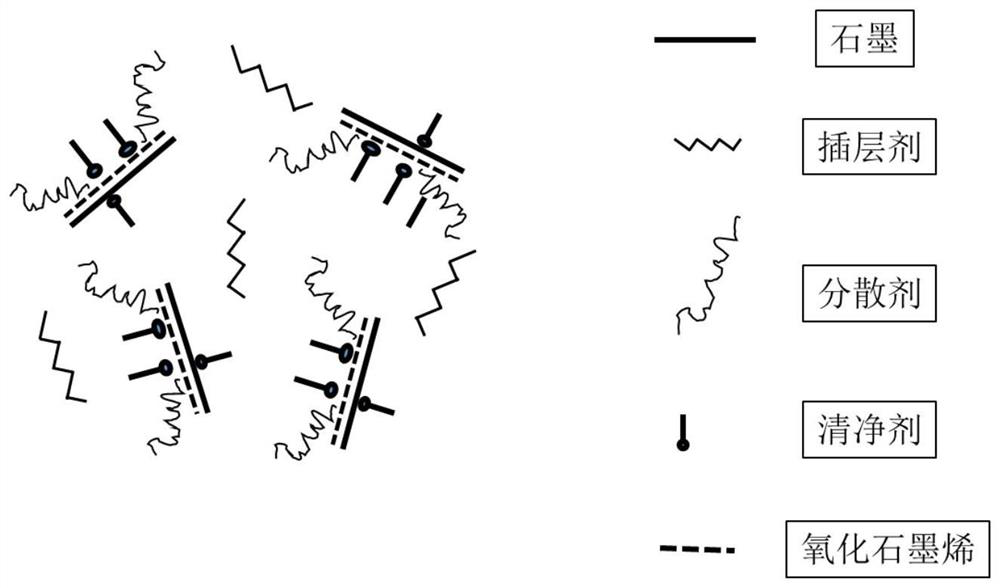

A lubricating oil additive, graphene technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of poor lubrication effect of graphene oxide, low success rate and efficiency of modification, complex modification process, etc., to achieve Easy in-situ peeling, excellent anti-friction and anti-wear effects, and rich functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

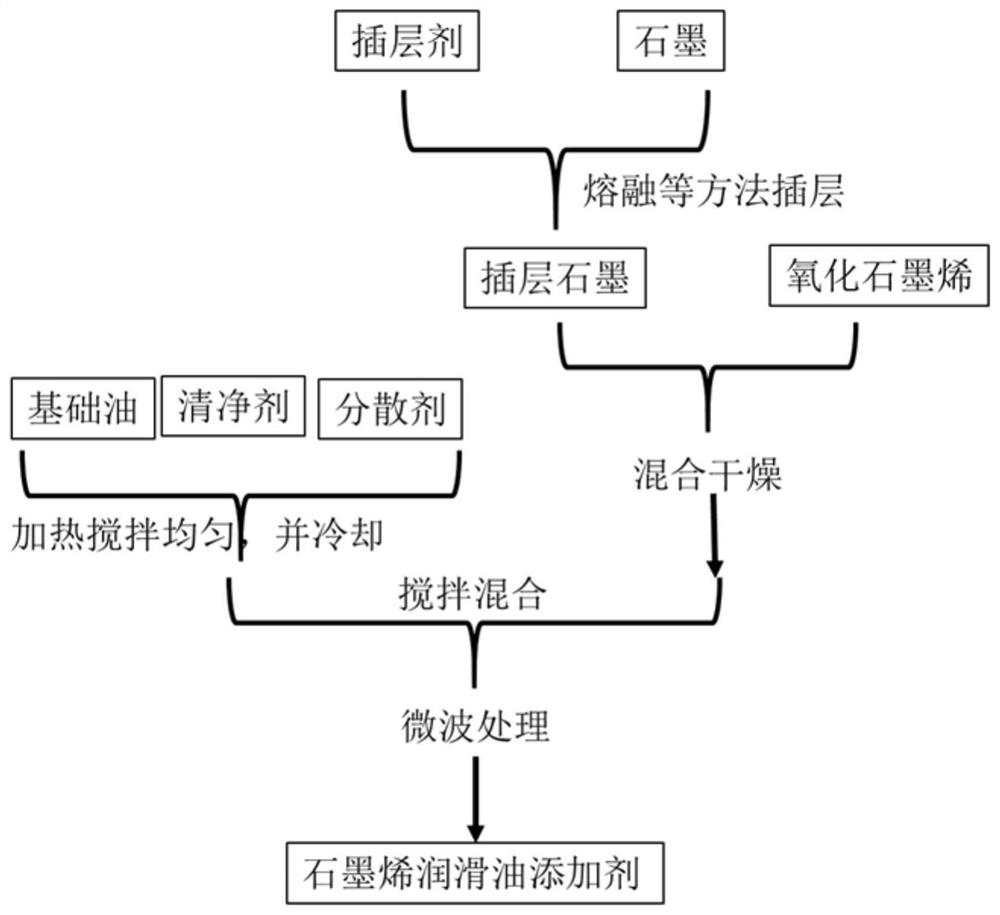

Method used

Image

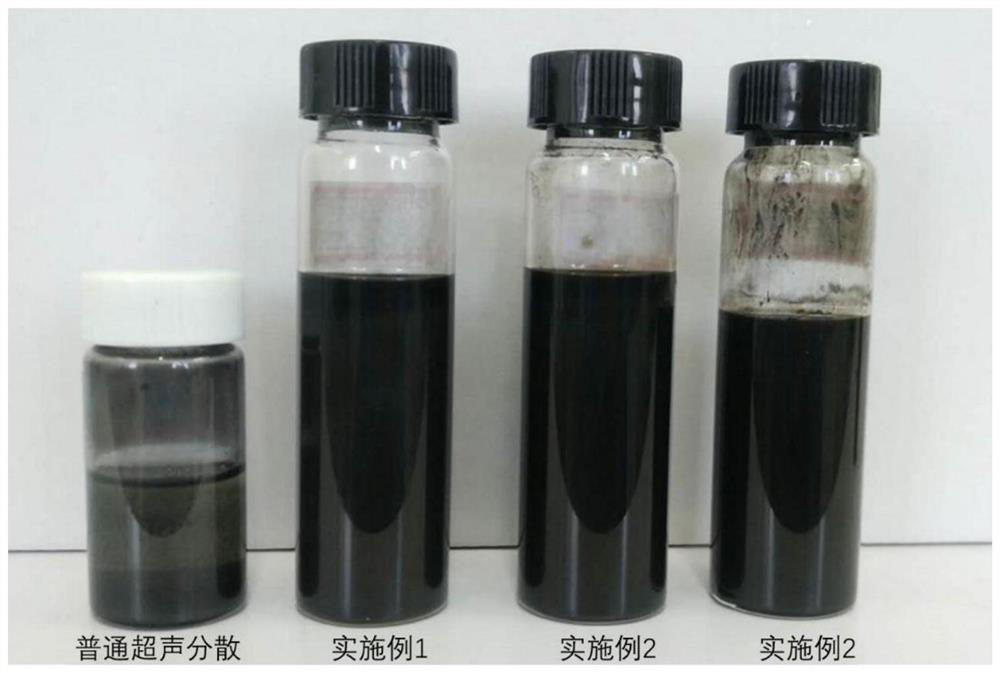

Examples

Embodiment 1

[0048] A preparation method for graphene lubricating oil additive, comprises the steps:

[0049] 1. Select ordinary graphite powder with an average particle size of 1.0 μm and anhydrous ferric chloride FeCl3, and prepare FeCl3 intercalated graphite by molten salt method:

[0050] At 80°C, mix FeCl3 and graphite powder into heat-resistant glass tubes, the molar ratio of the two is 1:15, vacuumize to 10.3Pa at 120°C, seal the glass tubes, and then heat them at 380 React at ℃ for 48h, cool to room temperature and take out the product;

[0051] 2. Wash the obtained FeCl3 intercalated graphite powder to remove excess FeCl3, then dry it, then add it to the 0.5mg / ml graphene oxide aqueous solution, so that the mass ratio of graphene oxide and intercalated graphite is 1:1, Stir and disperse evenly, dry in an oven at 50°C to obtain intercalated graphite / graphene oxide blend powder;

[0052] 3. Take 5 parts by weight of T106D detergent, 15 parts by weight of T161 dispersant, and 10 pa...

Embodiment 2

[0056] A preparation method for graphene lubricating oil additive, comprises the steps:

[0057] 1. Use ordinary graphite powder with an average particle size of 1.6 μm as raw material, triethyl phosphate as intercalation agent, and prepare triethyl phosphate intercalated graphite by solvothermal method:

[0058] Mix expanded graphite and triethyl phosphate evenly, the mass ratio of expanded graphite and triethyl phosphate is 1:3.5, add it into a high-pressure reactor, react at 120°C for 2 hours, cool to room temperature, and centrifuge to collect the precipitate to obtain the product;

[0059] 2. The prepared intercalated graphite powder is washed with water and ethanol, dried, and then added to the graphene oxide water / isopropanol (volume ratio of water and isopropanol is 3:1) solution of 1mg / ml, Make the mass ratio of graphene oxide and intercalated graphite to be 0.5:1, stir and disperse evenly, freeze-dry to intercalated graphite / graphene oxide blend powder;

[0060] 3. ...

Embodiment 3

[0062] A preparation method for graphene lubricating oil additive, comprises the steps:

[0063] 1. Select ordinary graphite powder with an average particle size of 2.6 μm as raw material, coconut oil alkanolamide phosphate, anhydrous ferrous chloride as intercalation agent, and prepare intercalated graphite by solvothermal method:

[0064] Dissolve 0.2 parts by weight of anhydrous ferrous chloride in 3 parts by weight of coconut oil alkanolamide phosphate, add 1 part by weight of graphite oxide powder and mix evenly, add it to the autoclave, react at 150 ° C for 1 hour, and cool Take it out at room temperature, centrifuge to get the precipitate to obtain the product;

[0065] 2. The prepared intercalated graphite powder is washed with water and ethanol, dried, and then added to the graphene oxide ethanol / water (volume ratio of ethanol and water is 1:3) solution of 1 mg / ml to make graphene oxide The mass ratio to intercalated graphite is 2:1, uniformly dispersed, freeze-dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com