High-mechanical-strength GO/TPU (Graphene Oxide/Thermoplastic Polyurethane) in-situ polymerization method

A technology of mechanical strength and in-situ polymerization, applied in the field of in-situ polymerization of high mechanical strength GO/TPU, can solve the problems of poor dispersion of graphene oxide, achieve performance improvement, increase elongation at break, and avoid the lack of reaction degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

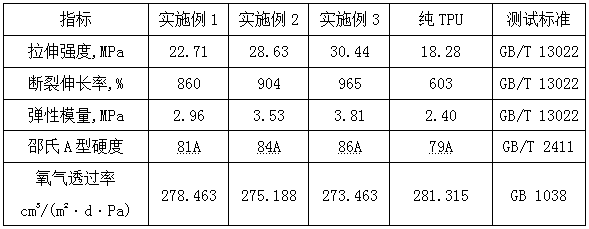

Examples

Embodiment 1

[0029] A kind of high mechanical strength GO / TPU in-situ polymerization method, the raw material of described GO / TPU comprises by weight parts:

[0030] 0.05 parts of graphene oxide (graphene oxide accounts for the percentage of TPU mass);

[0031] Polypropylene glycol-4000 60.0 parts;

[0032] 27.4 parts of toluene diisocyanate;

[0033] 1,4-butanediol 12.6 parts.

[0034] The polypropylene glycol-4000 is a colorless transparent oily viscous liquid, the hydroxyl value is 26-30 mg KOH / g, the molecular weight is 3700-4300, and the acid value is less than 0.5 mgKOH / g.

[0035] Described toluene diisocyanate is TDI-80, namely 80% toluene-2,4-diisocyanate (2,4-TDI) and 20% toluene-2,6-diisocyanate (2,6-TDI), acidity 0.004% Below, colorless to light yellow transparent liquid, molecular weight 174.16.

[0036] The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12 and a hydroxyl value of 1000-1200 mg KOH / g.

[0037]The graphene oxide is sequentia...

Embodiment 2

[0044] A kind of high mechanical strength GO / TPU in-situ polymerization method, the raw material of described GO / TPU comprises by weight parts:

[0045] 0.08 parts of graphene oxide (graphene oxide accounts for the percentage of TPU mass);

[0046] Polypropylene glycol-4000 60.0 parts;

[0047] 27.4 parts of toluene diisocyanate;

[0048] 1,4-butanediol 12.6 parts.

[0049] The polypropylene glycol-4000 is a colorless transparent oily viscous liquid, the hydroxyl value is 26-30 mg KOH / g, the molecular weight is 3700-4300, and the acid value is less than 0.5 mgKOH / g.

[0050] Described toluene diisocyanate is TDI-80, namely 80% toluene-2,4-diisocyanate (2,4-TDI) and 20% toluene-2,6-diisocyanate (2,6-TDI), acidity 0.004% Below, colorless to light yellow transparent liquid, molecular weight 174.16.

[0051] The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12 and a hydroxyl value of 1000-1200 mg KOH / g.

[0052] The graphene oxide is sequenti...

Embodiment 3

[0059] A kind of high mechanical strength GO / TPU in-situ polymerization method, the raw material of described GO / TPU comprises by weight parts:

[0060] Graphene oxide 0.1 part (graphene oxide accounts for the percentage of TPU mass);

[0061] Polypropylene glycol-4000 60.0 parts;

[0062] 27.4 parts of toluene diisocyanate;

[0063] 1,4-butanediol 12.6 parts.

[0064] The polypropylene glycol-4000 is a colorless transparent oily viscous liquid, the hydroxyl value is 26-30 mg KOH / g, the molecular weight is 3700-4300, and the acid value is less than 0.5 mgKOH / g.

[0065] Described toluene diisocyanate is TDI-80, namely 80% toluene-2,4-diisocyanate (2,4-TDI) and 20% toluene-2,6-diisocyanate (2,6-TDI), acidity 0.004% Below, colorless to light yellow transparent liquid, molecular weight 174.16.

[0066] The 1,4-butanediol is a colorless viscous oily liquid with a molecular weight of 90.12 and a hydroxyl value of 1000-1200 mg KOH / g.

[0067] The graphene oxide is sequentially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com