Double antibacterial non-woven fabric and preparation method thereof

A non-woven and dual technology, applied in the field of dual antibacterial non-woven fabrics and their preparation, can solve the problems of insufficient antibacterial properties, difficult to achieve washing resistance and durable antibacterial properties, etc. Excellent performance and washability, solve the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

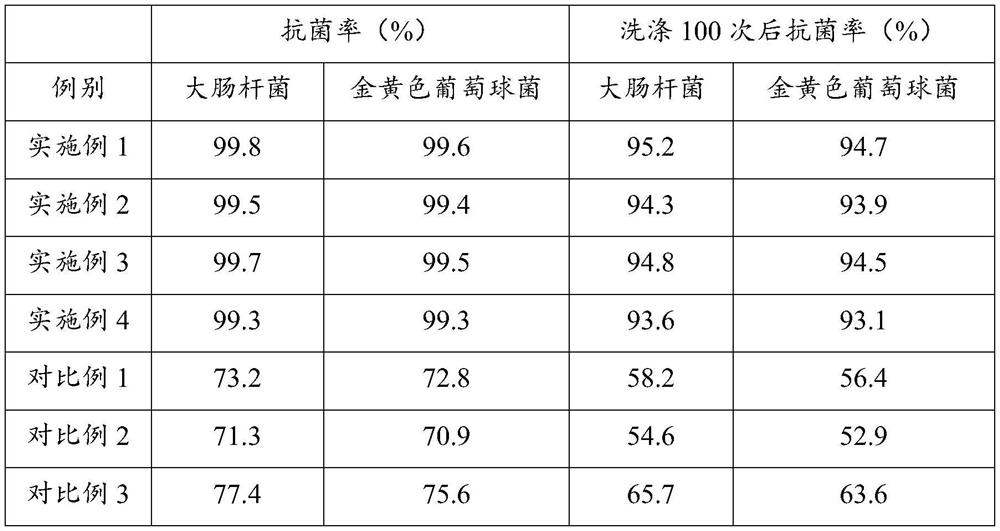

Examples

Embodiment 1

[0029] This embodiment provides a double antibacterial non-woven fabric, which is prepared by the following method:

[0030] Dissolve 5.95g (0.02mol) of zinc nitrate hexahydrate in 40mL of water to obtain solution A; dissolve 0.34g (0.002mol) of silver nitrate, 9.85g (0.12mol) of 2-methylimidazole, and 4g of PEG in 60mL of water to obtain solution B ;Soak the PP non-woven fabric treated with plasma in solution A at room temperature for 8 hours, take it out and dry it at 100°C for 20 minutes; then soak it in solution B at room temperature for 10 hours, take it out and treat it at 120°C for 30 minutes, The non-woven fabric was cleaned and dried at 80°C for 20 minutes; the treated non-woven fabric was soaked again in an aqueous sodium citrate solution with a concentration of 0.1mol / L for 8 hours, and dried at 100°C for 20 minutes; an antibacterial non-woven fabric was obtained.

Embodiment 2

[0032] This embodiment provides a double antibacterial non-woven fabric, which is prepared by the following method:

[0033] Dissolve 5.95g (0.02mol) of zinc nitrate hexahydrate in 40mL of water to obtain solution A; dissolve 0.34g (0.002mol) of silver nitrate, 9.85g (0.12mol) of 2-methylimidazole, and 4g of PEG in 60mL of water to obtain solution B ;Soak the PP non-woven fabric treated with plasma in solution A at room temperature for 4 hours, take it out and dry it at 100°C for 20 minutes; The non-woven fabric was cleaned and dried at 80°C for 20 minutes; the treated non-woven fabric was soaked again in a sodium citrate aqueous solution with a concentration of 0.1 mol / L for 6 hours, and dried at 100°C for 20 minutes; an antibacterial non-woven fabric was obtained.

Embodiment 3

[0035] This embodiment provides a double antibacterial non-woven fabric, which is prepared by the following method:

[0036] Dissolve 8.92g (0.03mol) of zinc nitrate hexahydrate in 40mL of water to obtain solution A; dissolve 0.51g (0.003mol) of silver nitrate, 14.78g (0.18mol) of 2-methylimidazole, and 4g of PEG in 60mL of water to obtain solution B ;Soak the PP non-woven fabric treated with plasma in solution A at room temperature for 4 hours, take it out and dry it at 100°C for 20 minutes; The non-woven fabric was cleaned and dried at 80°C for 20 minutes; the treated non-woven fabric was soaked again in a sodium citrate aqueous solution with a concentration of 0.1 mol / L for 6 hours, and dried at 100°C for 20 minutes; an antibacterial non-woven fabric was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com