Use of carboxyl-terminated hyperbranched polyester as luminescent material

A technology of hyperbranched polyester and terminal hydroxyl hyperbranching, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high price and high production cost of phosphor powder, and achieve the effect of avoiding easy reunion and solving the problem of high production finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 0.25g of carboxyl-terminated hyperbranched polyester I and dissolve it in 1ml of N,N-dimethylformamide, add it to 4g of EP-3401A, stir and mix evenly, desolventize at a vacuum of 0.1MPa at 120°C for 120min, add 4g EP-3401BRM, stir and mix evenly, evenly coat on the mold, defoam at 0.05MPa at 60°C for 60min, then transfer the mold to an ordinary oven, cure at 120°C for 90min, demould, and get blue fluorescent composite Membrane I. The structural formula of above-mentioned carboxyl-terminated hyperbranched polyester I is as follows:

[0033]

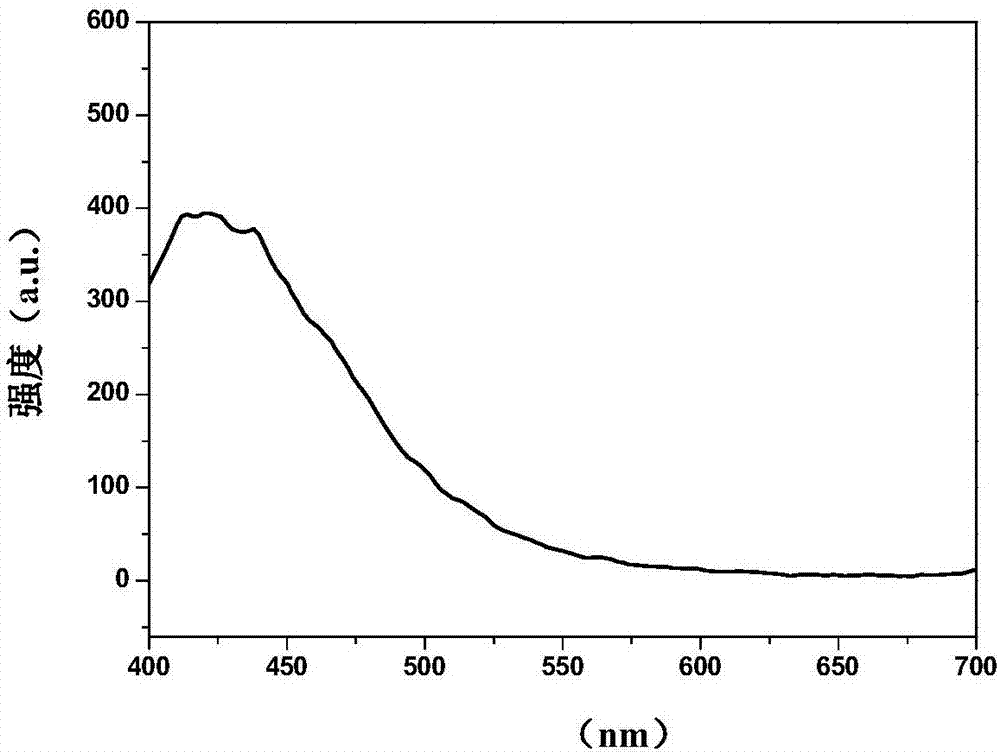

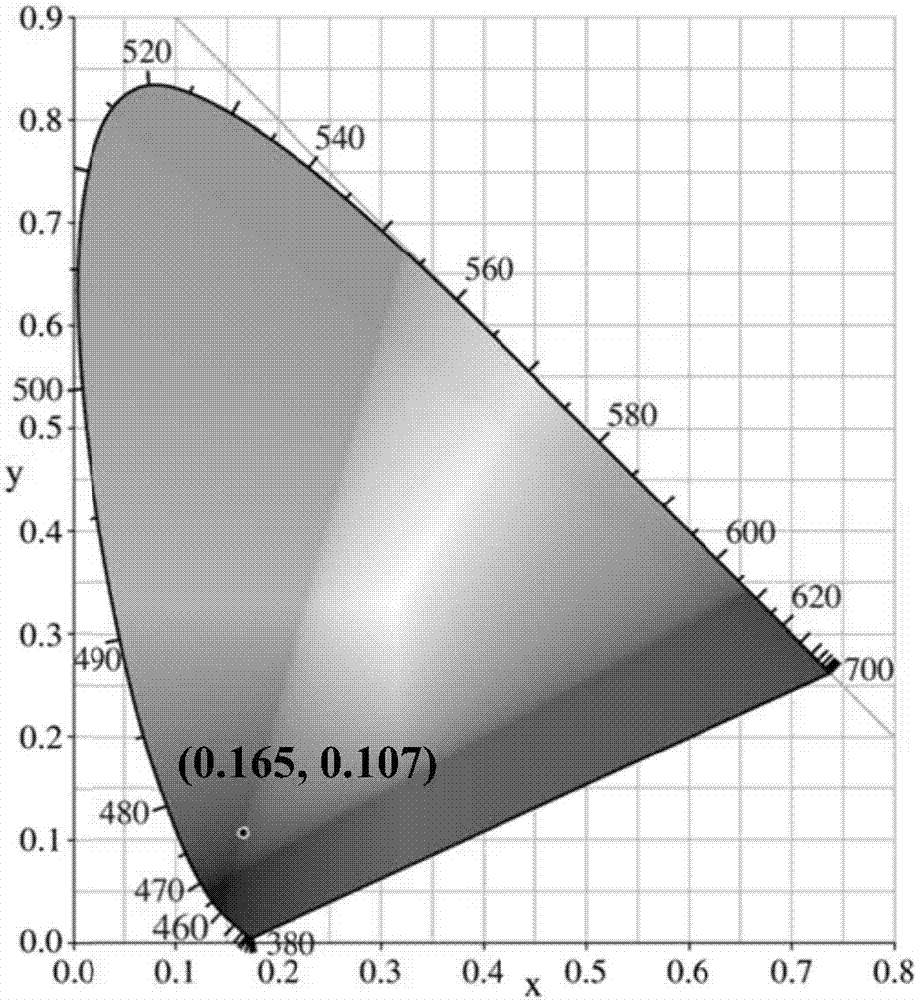

[0034] attached figure 1 It is the N of carboxyl-terminated hyperbranched polyester I, the fluorescence emission spectrogram of N-dimethylformamide solution sample under the excitation of 355nm, it can be seen that the carboxyl-terminated hyperbranched polyester I has a stronger intensity in the range of 400-450nm fluorescence emission. According to attached figure 1 The color coordinates of the N,N-dimethylformamide so...

Embodiment 2

[0040] Weigh 0.50g carboxyl-terminated hyperbranched polyester II, dissolve it in 1.5ml dimethyl sulfoxide, add it to 4g EP-3401A, stir and mix evenly, desolventize at 0.1MPa 130℃ for 120min, add 4gEP-3401BRM , stirred and mixed evenly, evenly coated on the mold, defoamed at a vacuum of 0.05MPa at 60°C for 80 minutes, then transferred the mold to an ordinary oven, cured at 120°C for 100 minutes, and demolded to obtain the blue fluorescent composite film II. The structural formula of the above-mentioned carboxyl-terminated hyperbranched polyester II is as follows:

[0041]

Embodiment 3

[0043] Weigh 0.25g carboxyl-terminated hyperbranched polyester III, dissolve it in 1ml N,N-dimethylacetamide, add it to 4g EP-3401A, stir and mix evenly, desolventize at 0.1MPa 120℃ for 120min, add 4g EP-3401BRM, stir and mix evenly, evenly coat on the mold, defoam at 0.05MPa at 60°C for 60min, then transfer the mold to an ordinary oven, cure at 110°C for 110min, demould, and get blue fluorescence Composite Membranes III. The structural formula of the above-mentioned carboxyl-terminated hyperbranched polyester III is as follows:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com