A kind of noble metal porous nano film and preparation method thereof

A noble metal and nano-membrane technology, applied in the field of nano-materials, can solve the problems of cumbersome process and long time consumption, achieve high electrochemical catalytic activity, reduce surface energy, and avoid easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment provides a kind of preparation of palladium porous nano-membrane, and its specific operation steps are as follows:

[0033] 1) Add 100 μL Na 2 PdCl 4 Solution (10mM) and 1.1mg cetylpyridinium chloride are placed in a beaker, and 10mL deionized water is added to obtain a precursor solution;

[0034] 2) Heat the precursor solution obtained in step 1) to boiling, add 100 μL of ascorbic acid solution (0.1M) when bubbles are generated in the precursor solution, and continue heating until the nanoparticles gather on the water-air interface to form an obvious film;

[0035] 3) suck out the film obtained in step 2) with a dropper, wash and dry to obtain a palladium porous nano-membrane.

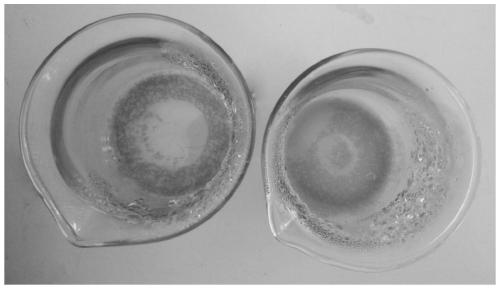

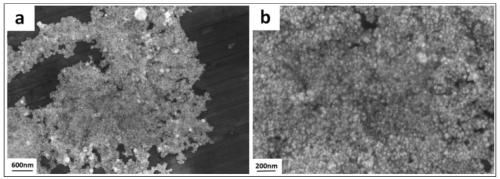

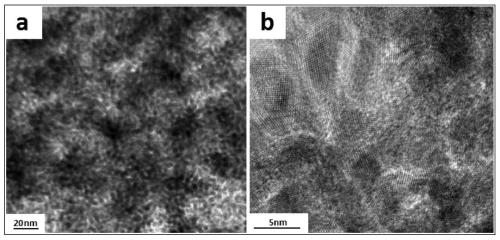

[0036] Such as figure 1 Shown is the photo of the palladium porous nano-membrane prepared in this embodiment, and it can be clearly observed that a thin film appears on the water-air interface. Such as figure 2 Shown is the scanning electron microscope photo of the...

Embodiment 2

[0040] This embodiment provides the preparation of a platinum porous nano-membrane, and its preparation method is similar to that of Example 1, except that 100 μL of Na 2 PdCl 4 Solution (10mM) was replaced with 100μL H 2 PtCl 6 ·6H 2 0 solution (10 mM).

[0041] Figure 4 Scanning electron micrograph of the porous nano-membrane prepared in this example. It can be seen from the scanning electron microscope pictures that the obtained product is a porous film material assembled by nanoparticles. The structure of the prepared platinum porous nano-membrane is similar to that of the product in Example 1. It is a layer of membrane structure assembled from many particles, and a clear porous structure can be seen.

Embodiment 3

[0043]The present embodiment provides the preparation of a kind of platinum-palladium bimetallic porous nano-membrane, and its preparation method is similar to embodiment 1, and difference is that step 1) adds Na 2 PdCl 4 After solution, add 100 μL HO 2 PtCl 6 ·6H 2 0 solution (10 mM).

[0044] Figure 5 Scanning electron micrograph of the porous nano-membrane prepared in this example. It can be seen from the scanning electron microscope pictures that the obtained product is a porous film material assembled by nanoparticles.

[0045] Image 6 , 7 and 8 are respectively the X-ray diffraction patterns of the noble metal porous membrane material obtained in Examples 1, 2 and 3. Compared with palladium and platinum standard PDF cards, it can be confirmed that the synthesized thin film material is palladium, platinum and platinum-palladium bimetallic respectively. and Image 6 , compared to 7, Figure 8 The XRD peaks of the platinum-palladium porous membrane shift slightly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com