A construction method for vibration forming cement stabilized crushed stone base

A cement-stabilized crushed stone and construction method technology, which is applied to roads, buildings, instruments, etc., can solve the problems of many cracks in the gravel base, cracks in the asphalt binder surface layer, and filling materials that cannot be compacted, so as to reduce cracks, Improve the life of the road and the effect of uniform gap filling of the roadbed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

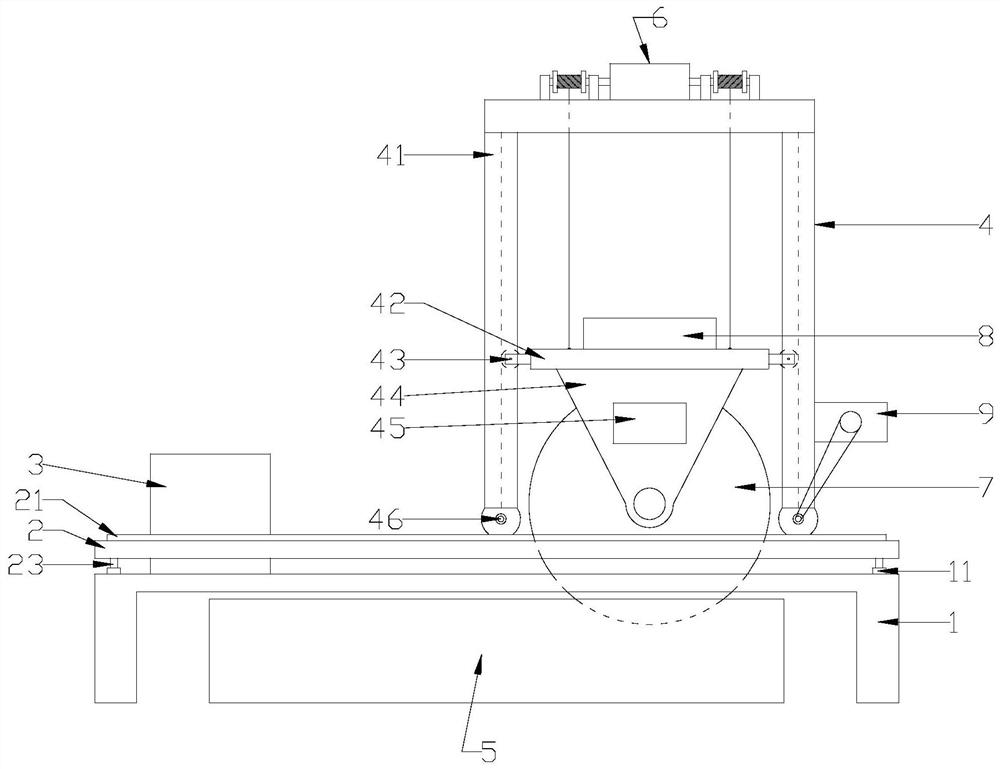

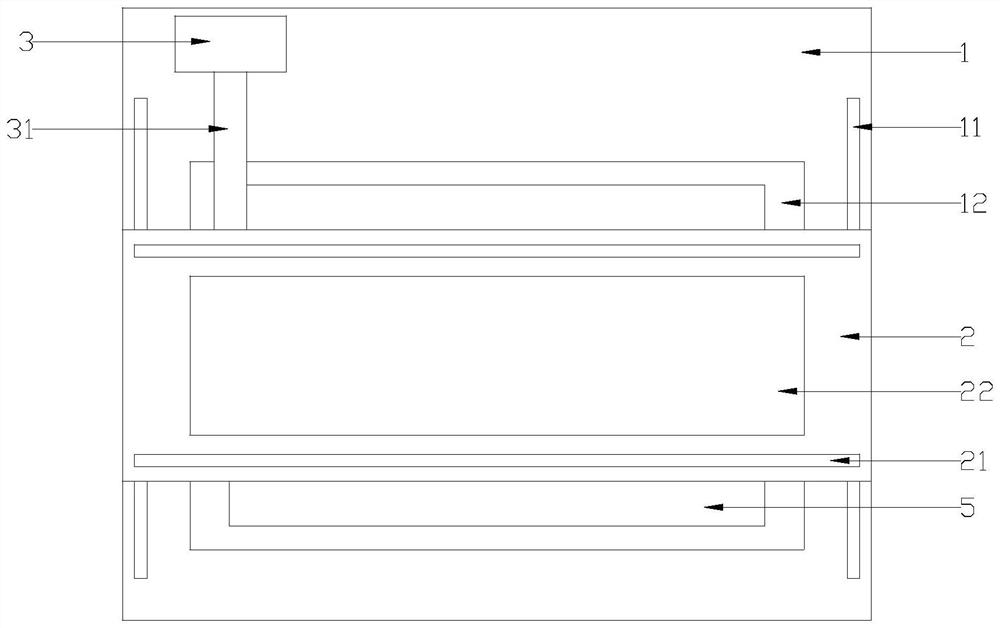

[0018] refer to figure 1 and figure 2 , the present invention a kind of vibration forming cement stabilized gravel base construction method, comprises the following steps:

[0019] a) Test: Add the cement mortar mixture into the sample box 5 of the vibratory compaction tester, place the sample box 5 under the first through hole 12, and carry out the test of the maximum dry density. In the frame 45, the weights of the counterweights in the hanging frame 45 on the side plates 44 on both sides should be the same, and the hoist 6 is used to lower the support plate 42 until the vibrating wheel 7 contacts the cement mortar mixture. Statically press the cement mortar mixture 1 to 3 times, and then make the vibrating wheel 7 vibrate the cement mortar mixture 3 to 7 times under the condition of vibration. The overlapping width of the vibration wheel 7 wheel tracks is 1 / 3~1 / 2 wheel width, the traveling speed of the mobile frame 4 along the second track 21 is 0.6~0.7m / s, after the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com