Rock anchor beam underground workshop excavation construction method under high ground stress condition

A technology of underground powerhouse and construction method, which is applied in excavation, artificial islands, water conservancy projects, etc. It can solve the problems of unfavorable surrounding rock stable rock platform forming quality, stress adjustment and relaxation damage, relaxation and collapse, etc., to ensure stability and formation The effect of quality, reduced damage, and reduced time to stress release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0022] In conjunction with the accompanying drawings.

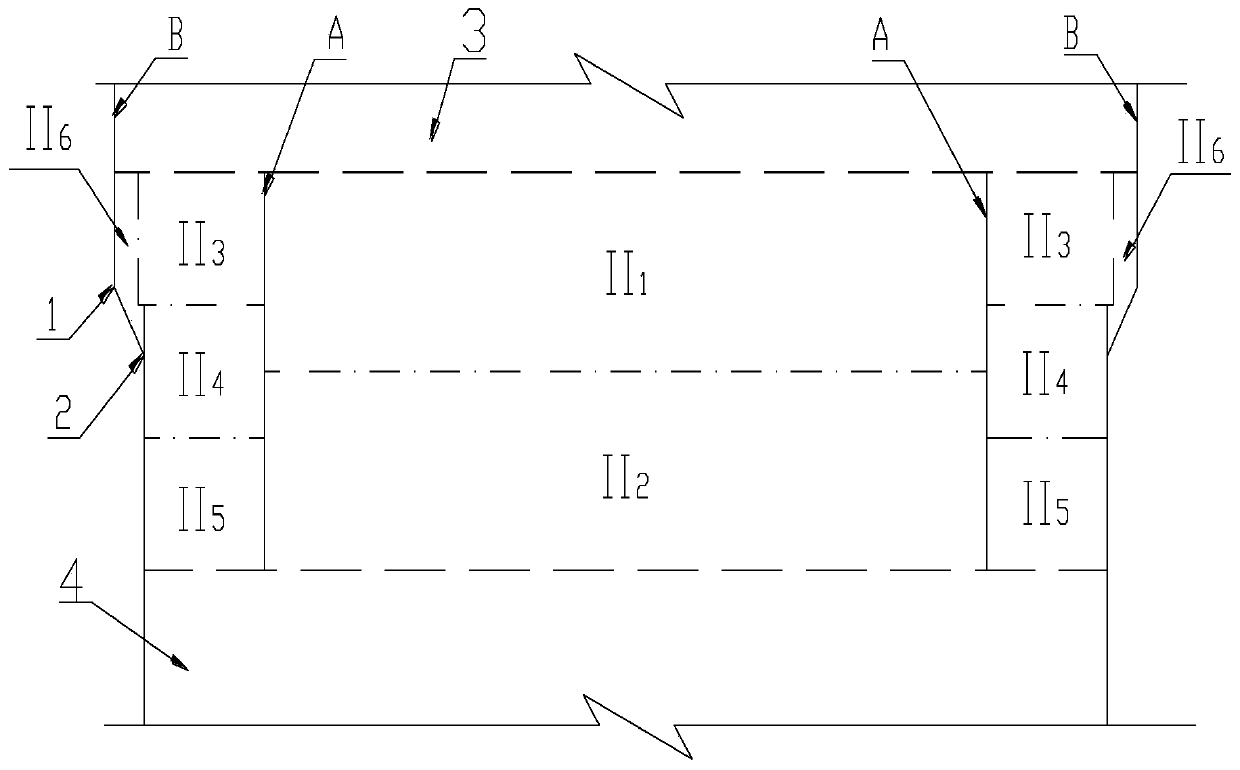

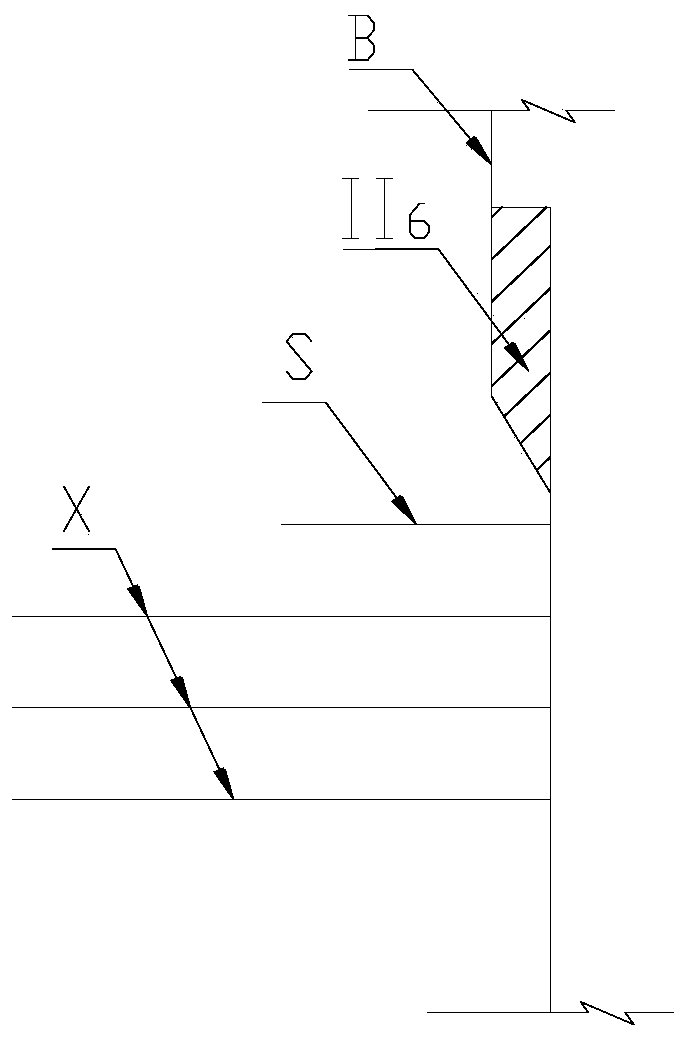

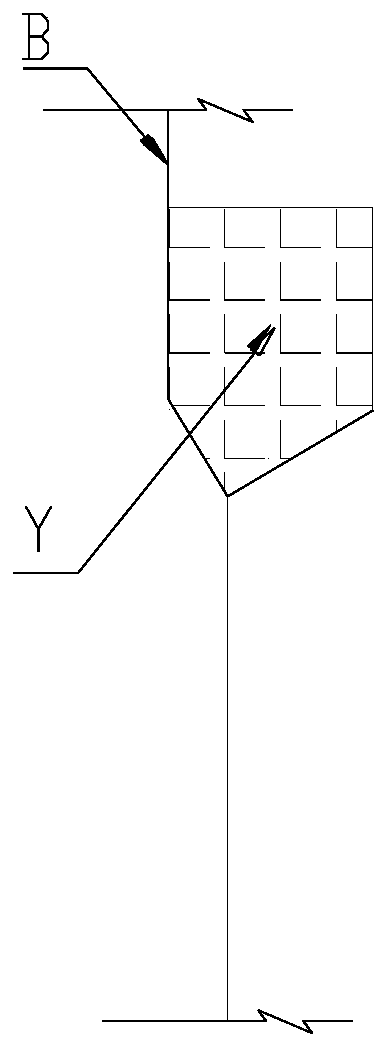

[0023] combine Figure 1 to Figure 2 .

[0024] The excavation of the rock anchor beam layer is divided into the upper layer of the middle groove, the upper layer of the protective layer, the lower layer of the middle groove, the middle layer of the protective layer, the lower layer of the protective layer and the excavation of the triangular body of the rock platform;

[0025] Pre-crack the protective layer on both sides of the rock anchor beam and the groove edge of the middle groove to form two pre-cracks. The pre-splitting holes between the protec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com