Vertical connecting sleeve suitable for building

A technology for connecting sleeves and buildings, which is applied in the direction of building structures, buildings, building components, etc., can solve the problems of increasing PM2.5 in the environment, low manufacturing efficiency, and difficulty in realization, so as to be easy to promote and use, and meet the installation positioning , the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

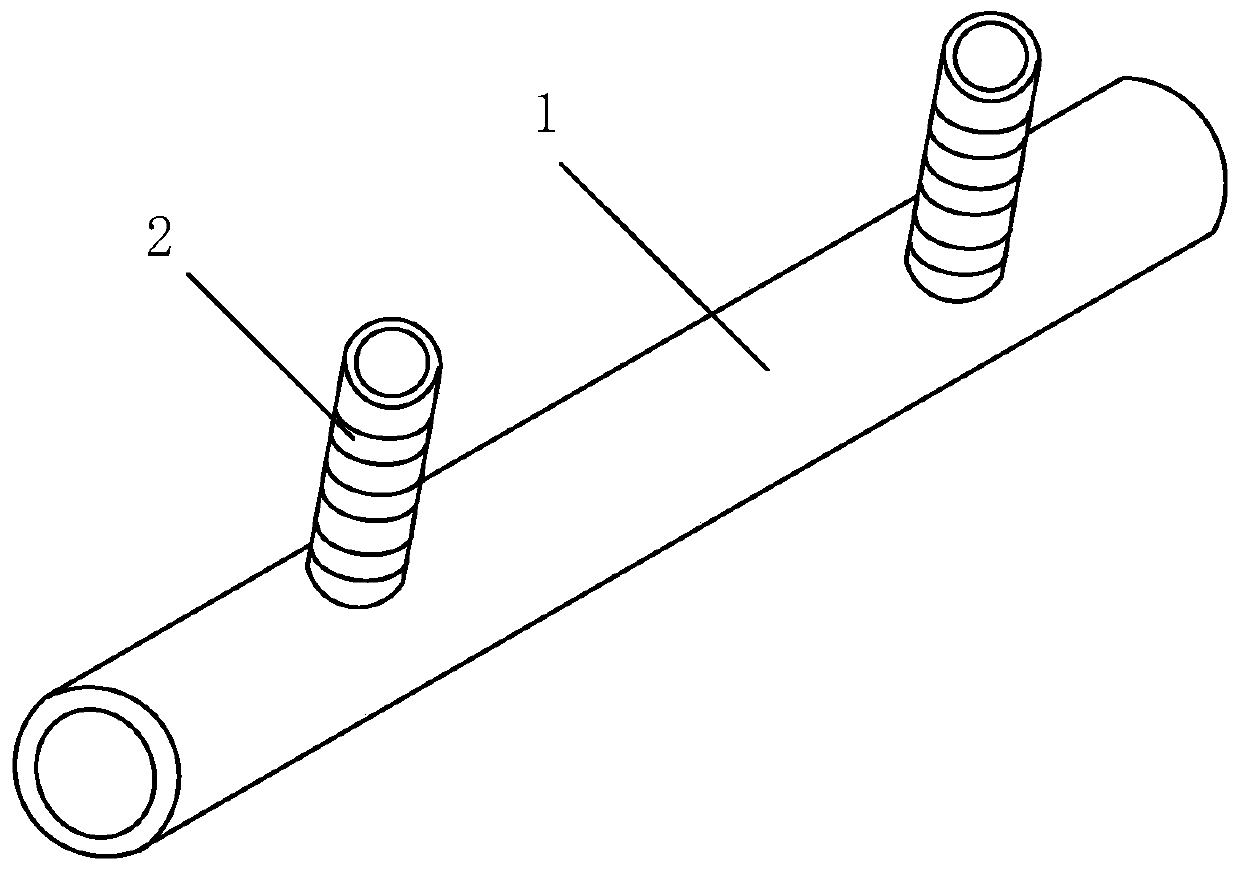

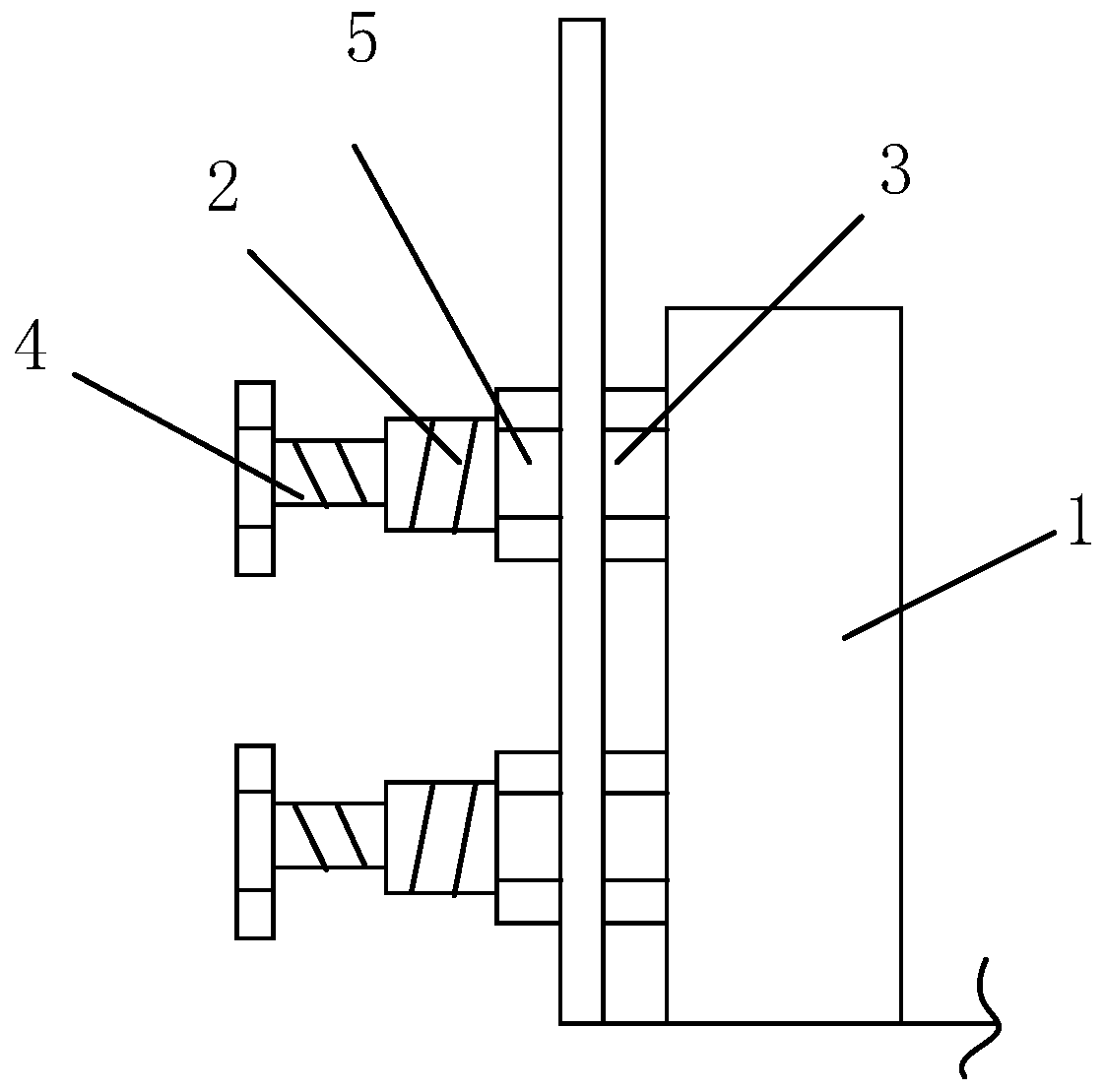

[0026] Such as figure 1 , figure 2 A vertical connection sleeve suitable for buildings includes a sleeve body 1, which is different in that: one side of the sleeve body 1 is provided with at least two vertically collinear connection components 2. At the same time, considering that during actual use, it can ensure that the present invention has an appropriate joint gap after being installed in place, which is convenient for subsequent grouting operations. Moreover, in order to carry out effective clamping connection and apply continuous inward stress to the sleeve body 1 , a jacking bolt 4 is connected to the connecting assembly 2 in the present invention.

[0027] In v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com