Breeze generator

A generator and breeze technology, which is applied to wind turbines, wind turbine combinations, wind turbine control, etc., can solve the problems of low wind energy conversion efficiency, limited frontal area of wind blades, and difficulty in generating electricity from wind turbines, so as to improve the conversion rate. , The effect of improving the driving performance and reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

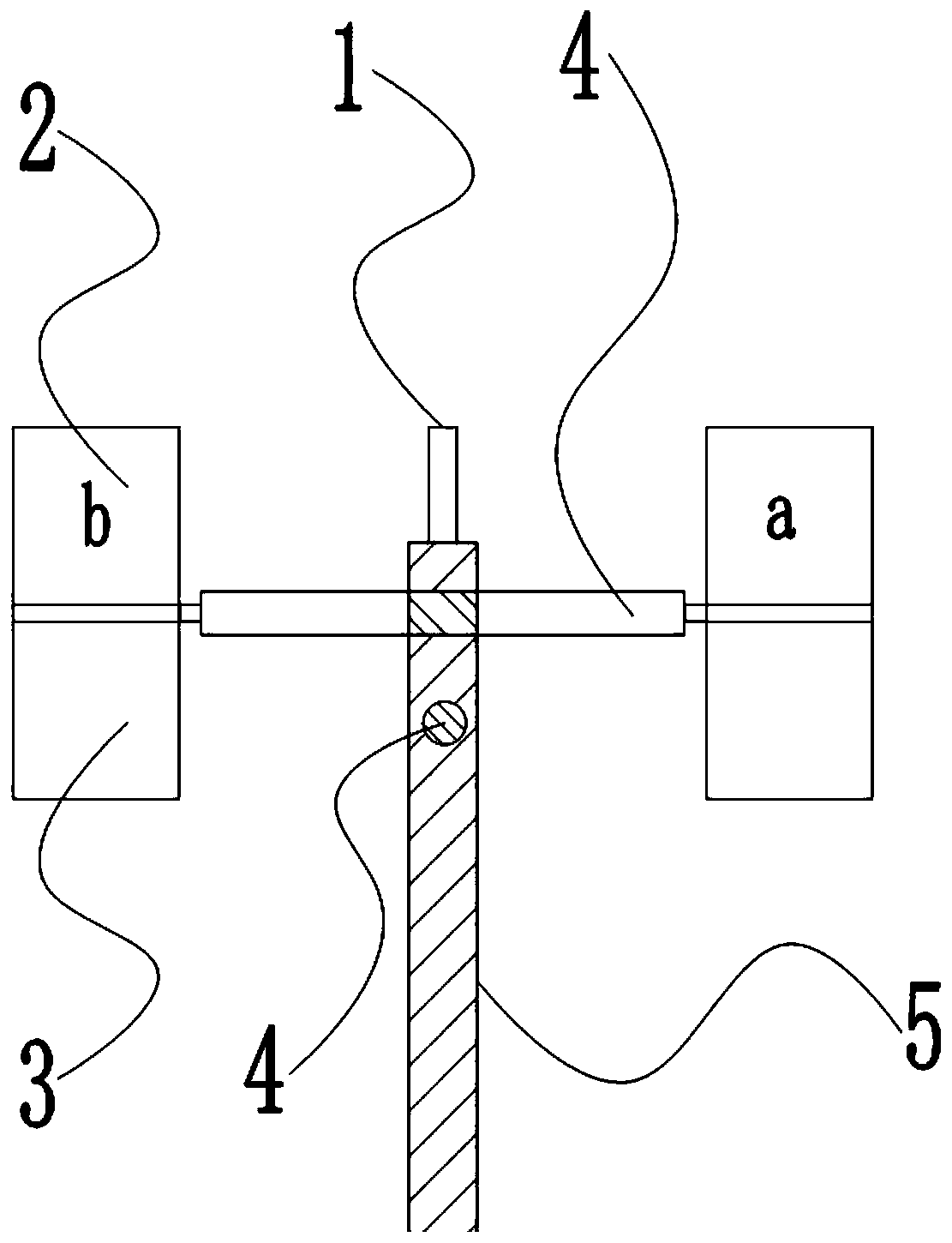

[0037] Such as figure 1 As shown, a kind of breeze generator comprises multiple sets of facing and vertically arranged wind blades 1, a plurality of connecting rods 4 arranged horizontally from bottom to top, a vertically arranged transmission shaft 5 with a hollow interior, and a power generating Machine, transmission unit, drive unit and control unit, one connecting rod 4 corresponds to a set of wind blades 1 facing oppositely.

[0038] Each wind blade 1 is composed of an upwind blade 2 and a downwind blade 3. The upwind blade 2 and the downwind blade 3 are hinged. The hinge is a one-way hinge point, and the hinge angle is 0°-180°. 2 is a reference object, and the downwind blade 3 can rotate clockwise relative to the upwind blade 2 .

[0039] Adjacent connecting rods 4 are perpendicular to each other, and each connecting rod 4 passes through the transmission shaft 5, and each connecting rod 4 can freely rotate along its own circumferential direction relative to the transmis...

Embodiment 2

[0051] The difference from Embodiment 1 is that in this embodiment, the breeze generator includes a pit installed under the generator. A touch switch is installed between the upwind blade and the downwind blade. The position of the touch switch is the position of the one-way handover point. An electric push rod supporting the generator is installed below the generator. When the upwind blade and the downwind blade are completely closed, the touch switch is triggered, the electric push rod is activated, and the electric push rod shrinks downward to drive the whole breeze generator into the pit. A temperature sensor is installed on the back side of the wind direction sensor, that is, on the opposite side of the wind blade where the wind direction sensor is installed, and the temperature sensor is electrically connected to the microcontroller. When the temperature sensor detects that the temperature is higher than the preset temperature value of the microcontroller, the microcon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap