Air suction drainage structure of electric air conditioner compressor for automobile

An electric air conditioner and compressor technology, applied in the field of auto parts, can solve the problems of disordered flow state, large pressure loss and pulsation, electronically controlled ablation, etc., to avoid excessive working temperature, reduce pressure loss, and reduce airflow pulsation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

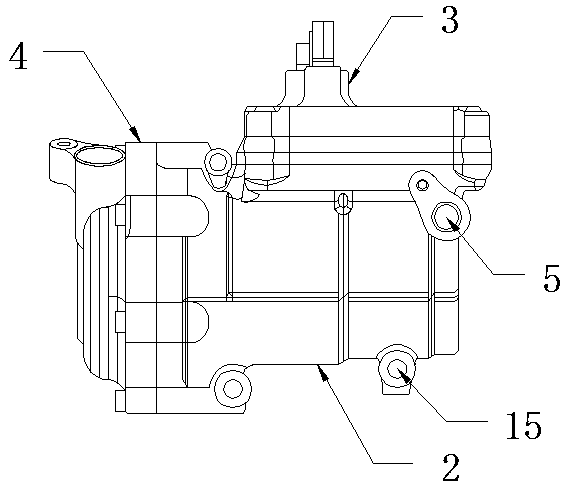

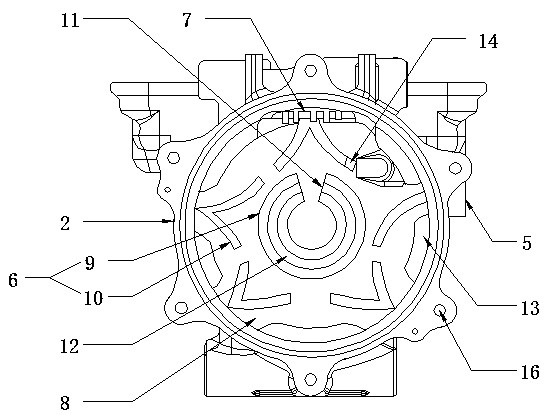

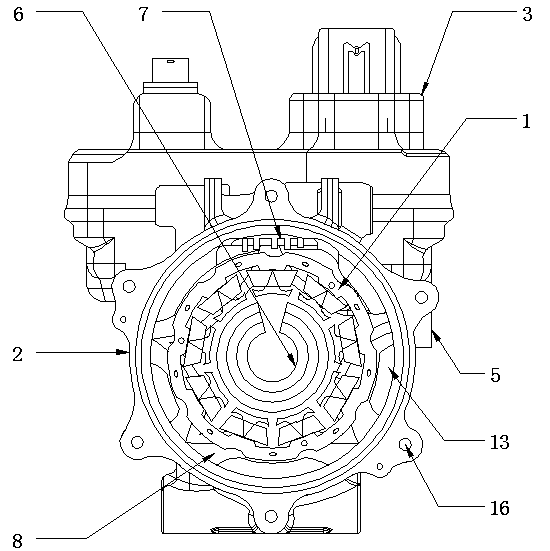

[0018] as attached Figure 1-3 As shown, the purpose of the present invention is achieved in this way: a kind of electric air-conditioning compressor suction and drainage structure for automobiles, including motor 1, motor casing 2, compressor electric control 3, pump body 4, suction port 5, suction Port diversion groove 6, electric control cooling grid 7, housing diversion groove 8, motor casing 2 is set on the motor 1, compressor electric control 3 is arranged on one side of the motor casing 2, and the One end of the motor 1 is provided with a pump body 4, one side of the motor casing 2 is provided with an air inlet 5, and the inner bottom surface of the motor casing 2 is provided with an air inlet guide groove 6, and the air inlet guide The flow groove 6 includes an annular flow guide block 9 and a herringbone flow guide block 10, the annular flow guide block 9 is provided with a gap 11, and the front of the annular flow guide block 9 is provided with an annular groove 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com