Fast response electromagnetic valve

A fast-response, solenoid valve technology, applied in valve details, valve devices, valve operation/release devices, etc., can solve problems such as slow response of the moving iron core, achieve the effect of ensuring safe application and improving response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

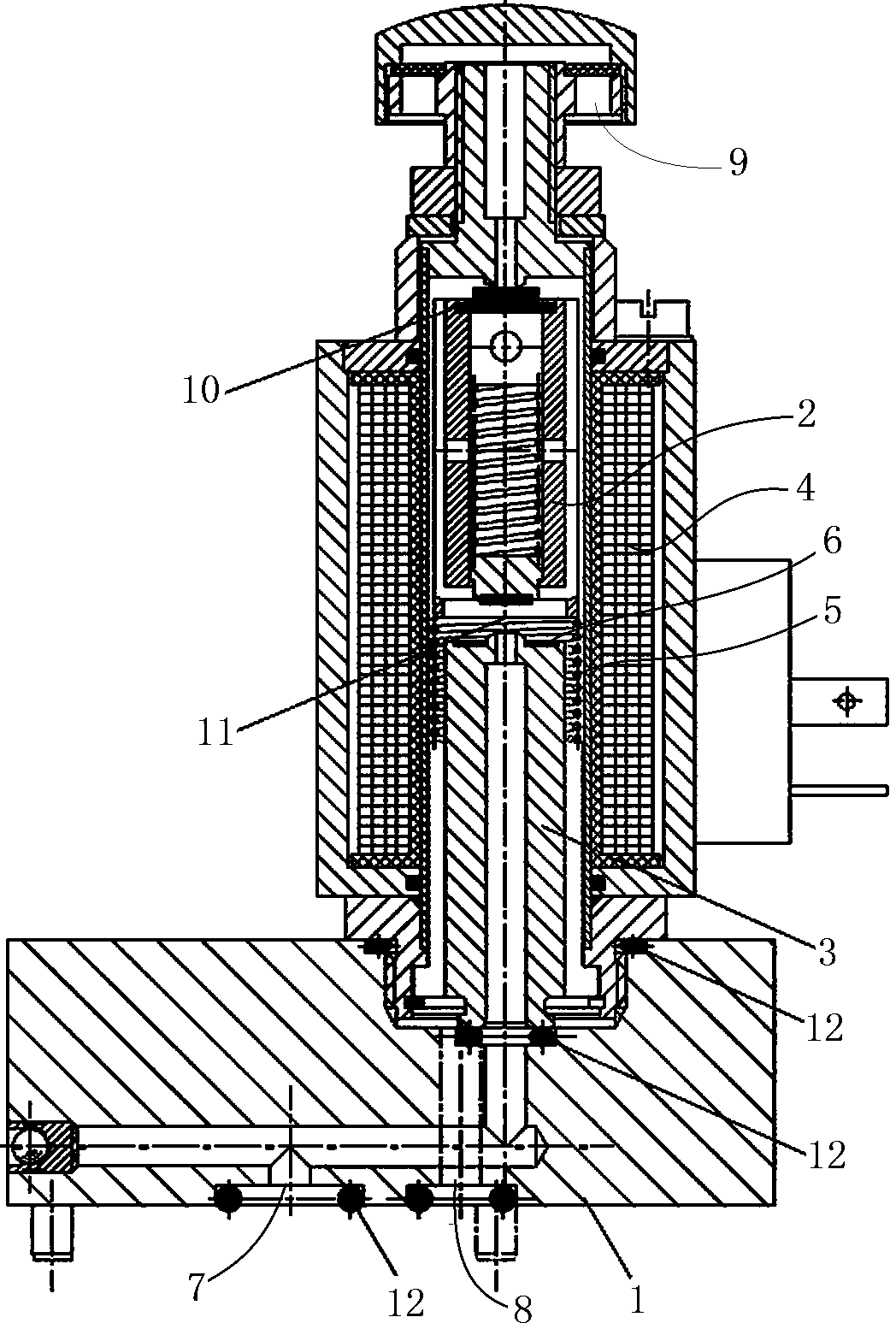

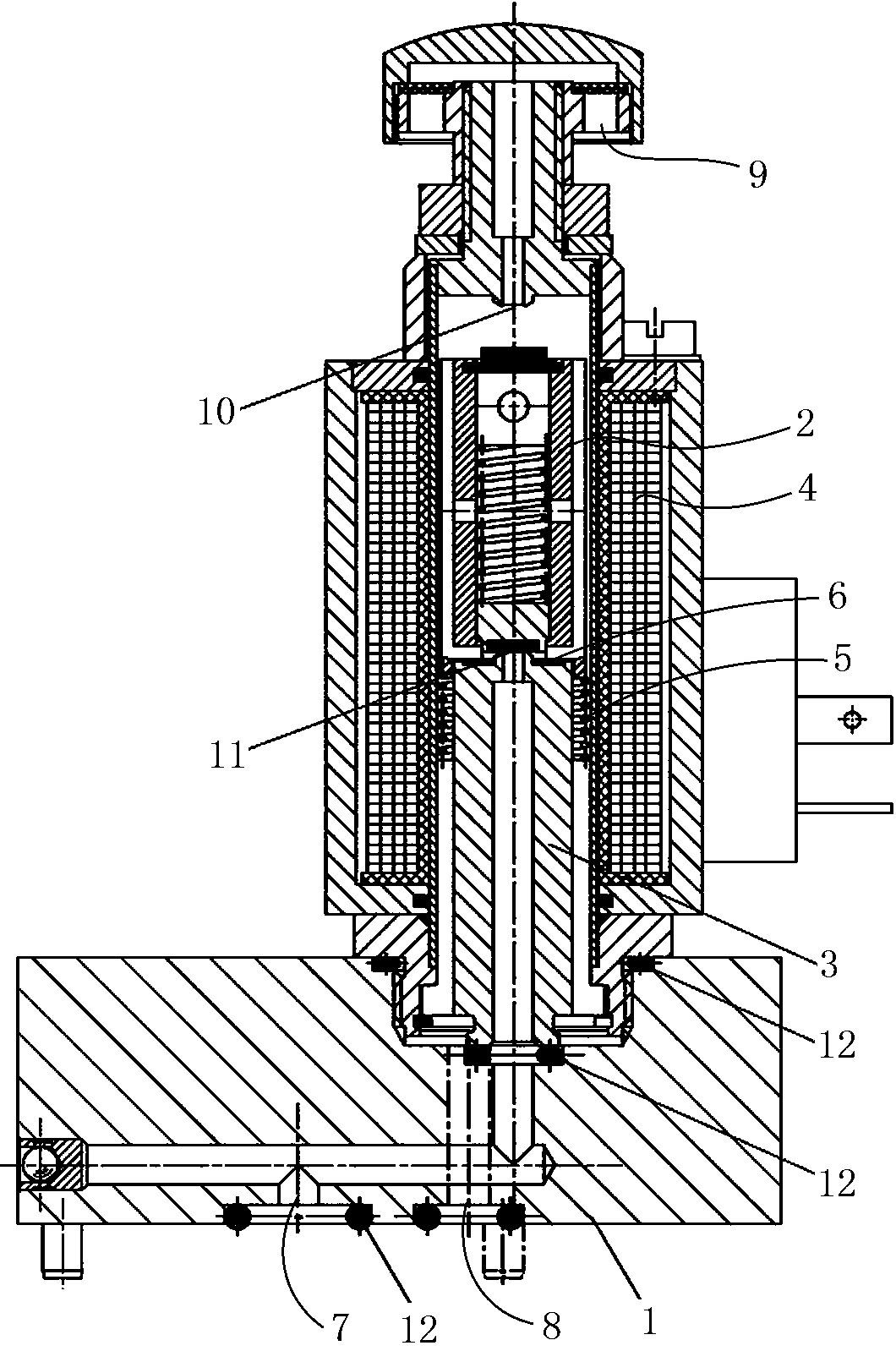

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

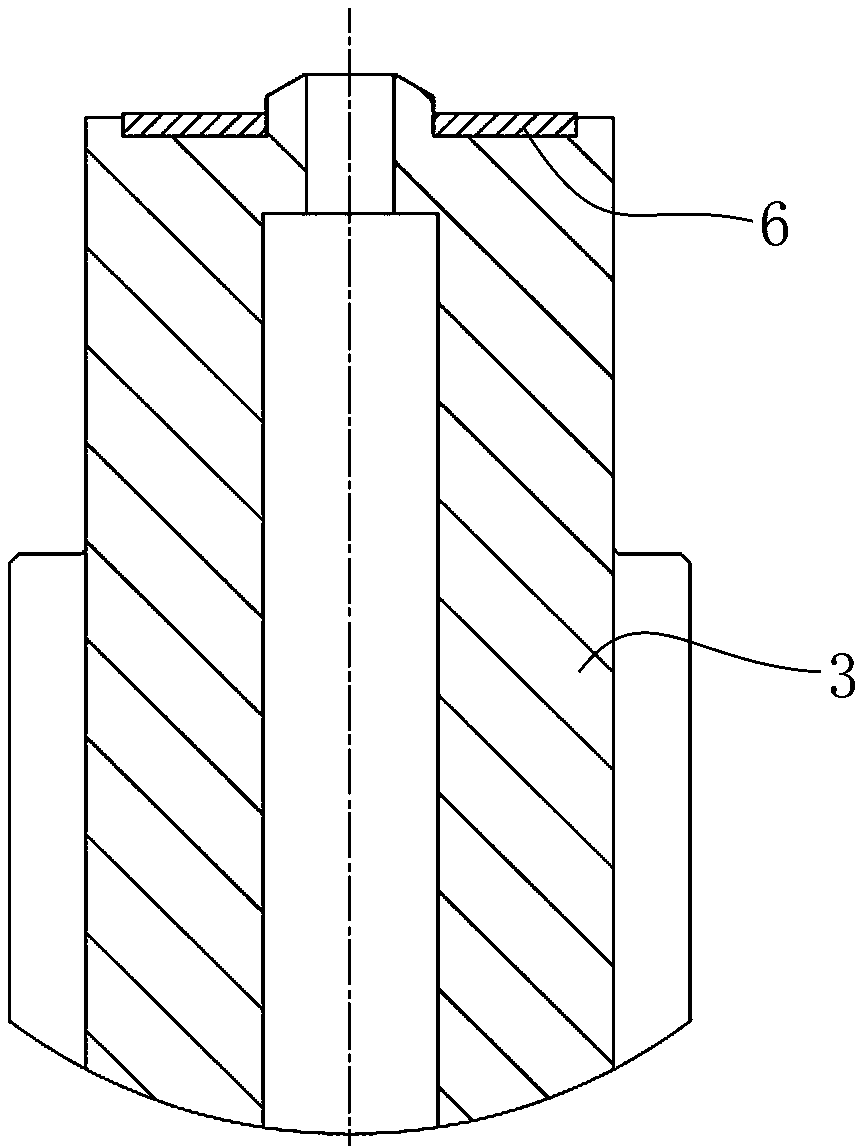

[0020] The specific embodiment of the quick response electromagnetic valve of the present invention, this is as figure 1 As shown, the quick-response solenoid valve is a solenoid valve used in the air supply and braking system of rail transit vehicles, and is used to charge and exhaust air for downstream equipment. The quick-response solenoid valve includes a valve body 1. The valve body 1 is L-shaped as a whole. The lower end of the horizontal section is provided with an air source inlet 7 and a product outlet 8. The air source inlet 7 is used to connect the air source or air supply source, and the product outlet 8 is used In connection with the downstream equipment, the upper part of the vertical section of the valve body 1 is provided with a vent 9, and the vent 9 directly communicates with the atmosphere. The vertical section of the valve body 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com