Double-unit pipe shell condenser and use method thereof

A condenser and shell-and-tube technology, applied in the field of double-machine shell-and-tube condensers, can solve the problems of a lot of waste of economic resources and space resources, starting and stopping units, complex structure, etc., to save economic resources and space resources, efficient and fast. The effect of heat exchange and ensuring the quality of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

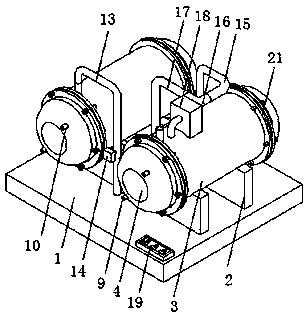

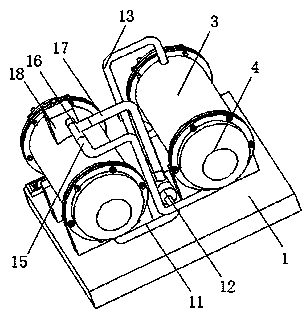

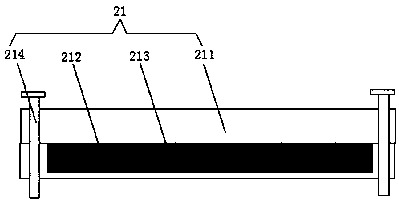

[0021]Embodiment 1: A dual-machine shell-and-tube condenser, including a bottom plate 1, two sets of symmetrically distributed bases 2 are provided on the upper end of the bottom plate 1 to provide bottom support, and the upper end of the base 2 is fixed below the two ends of the arc surface of the condenser tube 3 Connection, both ends of the condensation cylinder 3 are provided with a second connection device 21, the second connection device 21 includes a flange 211, and two symmetrically distributed flanges are provided on the outside of the surface of the condensation cylinder 3 and the inside of the surface of the tube box 4 Disc 211, the threaded holes at the upper ends of two symmetrically distributed flanges 211 are threaded through anti-rust bolts 214, and the inner flange 211 is provided with an annular groove 212 on the side away from the center of the condensation cylinder 3, and the groove of the annular groove 212 is A sealing rubber ring 213 is provided to ensure...

Embodiment 2

[0022] Embodiment 2: A dual-machine shell-and-tube condenser, including a bottom plate 1, two sets of symmetrically distributed bases 2 are provided on the upper end of the bottom plate 1 to provide bottom support, and the upper end of the base 2 is fixed below the two ends of the arc surface of the condenser tube 3 Connection, the two ends of the condensing cylinder 3 are provided with a second connecting device 21, which is convenient for disassembly and maintenance. The flange 211 on the outside of the second connecting device 21 is fixedly connected to the inner surface of the tube box 4, and the inner wall sides of the tube box 4 The tube plate 5 is symmetrically arranged, and the tube plate 5 provides the support of the heat exchange tube 6. The surface of the tube plate 5 is provided with evenly distributed adjustment holes and welded with the outer surface of the heat exchange tube 6, and the heat exchange tube 6 provides the input and exchange of heat material. heat, t...

Embodiment 3

[0023] Embodiment 3: A dual-machine shell-and-tube condenser, including a bottom plate 1, two sets of symmetrically distributed bases 2 are provided on the upper end of the bottom plate 1 to provide bottom support, and the upper end of the base 2 is fixed below the two ends of the arc surface of the condenser tube 3 Connection, both ends of the condensation cylinder 3 are provided with a second connection device 21, the second connection device 21 includes a flange 211, and two symmetrically distributed flanges are provided on the outside of the surface of the condensation cylinder 3 and the inside of the surface of the tube box 4 Disc 211, the threaded holes at the upper ends of two symmetrically distributed flanges 211 are threaded through anti-rust bolts 214, and the inner flange 211 is provided with an annular groove 212 on the side away from the center of the condensation cylinder 3, and the groove of the annular groove 212 is A sealing rubber ring 213 is provided, the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com