Method for detecting concrete slump through sound waves

A technology of acoustic wave detection and concrete, which is applied in the field of acoustic wave detection of concrete mixture slump, which can solve the problem that the concrete mixture slump cannot satisfy pumping, the loss of concrete mixture is not considered, and the concrete mixing is not considered It can reduce the amount of staffing, the measurement data is accurate and reliable, and the installation is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 Determine the relational expression of wave velocity v and slump SL changing with time

[0038] In order to realize the above-mentioned purpose of the invention, comprise the following steps:

[0039] (1) Concrete mixture 1 is configured according to the mix ratio listed in Table 1;

[0040] Table 1

[0041] water

the sand

pebbles

160kg

400kg

776kg

1164kg

[0042] (2) The raw materials configured in step (1) are mixed by the secondary feeding method (pre-mixed cement mortar method). First, put water, cement, and sand into the mixer, mix for 30 seconds to form cement mortar, and then put in stones and stir for 60 seconds to obtain mixing. homogeneous concrete mix 1;

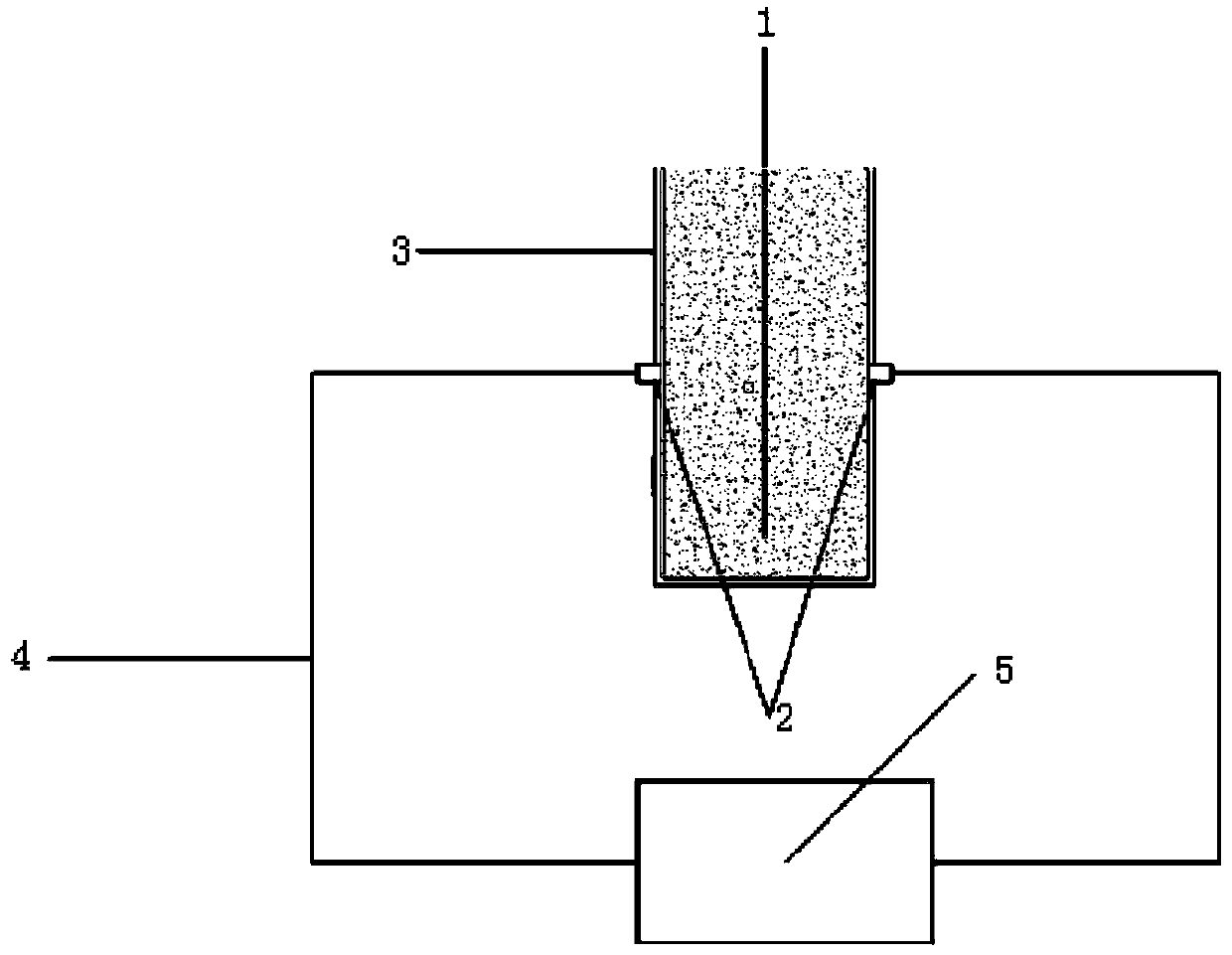

[0043] (3) Put the concrete mixture 1 stirred in step (2) into an acrylic box 3 with a size of 10cm*10cm*20cm and a wall thickness of 5mm, and open two holes on both sides of the acrylic box 3 with a height of 10cm A hole with a diameter...

Embodiment 2

[0054] Embodiment 2 verifies the correctness of embodiment 1 relational expression

[0055] Verification example 2-1:

[0056] The difference between verification example 2-1 and embodiment 1 is only that step (1) configures concrete mixture 1 according to the mix ratio listed in table 3:

[0057] table 3

[0058] water

cement

the sand

pebbles

170kg

400kg

772kg

1158kg

[0059] The measurement results of wave velocity and slump over time and the formula calculation results of this verification example are shown in Table 4:

[0060] Table 4

[0061]

[0062] Verification example 2-2:

[0063] The difference between verification example 2-2 and embodiment 1 is only that step (1) configures concrete mixture 1 according to the mix ratio listed in table 5:

[0064] table 5

[0065] water

cement

the sand

pebbles

180kg

400kg

768kg

1152kg

[0066] The measurement results and formula ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com