A kind of formation method that improves lithium-ion battery storage time

A technology of lithium-ion batteries and formation methods, which is applied in the field of formation of lithium-ion batteries to improve storage time, can solve problems such as battery deterioration, lithium dissolution, battery over-discharge, etc., to maintain rate performance, avoid internal resistance increase, and reduce self-discharge. The effect of discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

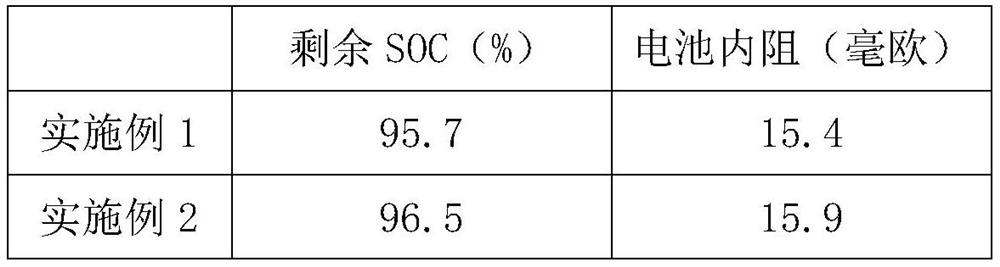

Embodiment 1

[0030] According to the proportion of the total mass of the electrolyte, FEC accounts for 0.5% of the electrolyte, and NaF is 0.005%, which includes the following steps:

[0031] 1), the lithium-ion battery after liquid injection was left to stand for 6 hours;

[0032] 2), constant current charging to 3.9V, the current size is 0.02C;

[0033] 3), let stand for 1h;

[0034] 4) Charge with a constant voltage of 3.9V until the charging current drops below 0.01C;

[0035] 5), constant current discharge to 3.1V, the current size is 0.1C;

[0036] 6), at 3.08-3.12V, carry out 5 times of small current charge and discharge cycle, the small current is 0.005C;

[0037] 7) Charge the battery with a constant current of 0.02C to the 3.9V;

[0038] 8), at 3.88-3.92V, carry out 5 small current charge and discharge cycles, and the small current is 0.005C;

[0039] 9) Charge at a constant current of 0.02C to 4.2V, and then charge at a constant voltage at this voltage until the charging cu...

Embodiment 2

[0042] According to the ratio of the total mass of the electrolyte, FEC accounts for 1.5% of the electrolyte, and NaF is 0.02%, which includes the following steps:

[0043] 1), the lithium-ion battery after liquid injection was left to stand for 6 hours;

[0044] 2), constant current charging to 4.0V, the current size is 0.04C;

[0045] 3), let stand for 6 hours;

[0046] 4) Charge at a constant voltage of 4.0V until the charging current drops below 0.01C;

[0047] 5), constant current discharge to 3.2V, the current size is 0.2C;

[0048] 6), at 3.18-3.22V, carry out 5 times of small current charge and discharge cycles, the small current is 0.01C;

[0049] 7) Charge the battery to the 4.0V with a constant current of 0.02-0.04C;

[0050] 8), at 3.98-4.02V, carry out a small current charge and discharge cycle for 5 times, and the small current is 0.01C;

[0051] 9) Charge at a constant current of 0.04C to 4.3V, and then charge at a constant voltage at this voltage until the...

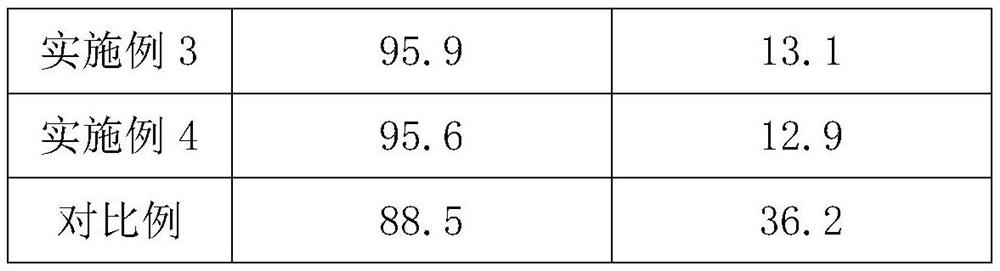

Embodiment 3

[0054] According to the ratio of the total mass of the electrolyte, FEC accounts for 1% of the electrolyte, and NaF is 0.01%, which includes the following steps:

[0055] 1), the lithium-ion battery after liquid injection was left to stand for 8 hours;

[0056] 2), constant current charging to 3.9V, the current size is 0.02C;

[0057] 3), let stand for 6 hours;

[0058] 4) Charge with a constant voltage of 3.9V until the charging current drops below 0.01C;

[0059] 5), constant current discharge to 3.1V, the current size is 0.1C;

[0060] 6), at 3.08-3.12V, carry out 10 cycles of charging and discharging with a small current, and the small current is 0.005C;

[0061] 7) Charge the battery with a constant current of 0.02C to the 3.9V;

[0062] 8), at 3.88-3.92V, carry out 10 cycles of charging and discharging with a small current, and the small current is 0.005C;

[0063] 9) Charge at a constant current of 0.02C to 4.2V, and then charge at a constant voltage at this voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com