Bilayer-type fermented milk product and production method therefor

A technology of fermented dairy products and manufacturing methods, which is applied in the direction of dairy products, other dairy products, and milk preparations, and can solve problems such as product value decline, damage to product appearance, and unclear interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

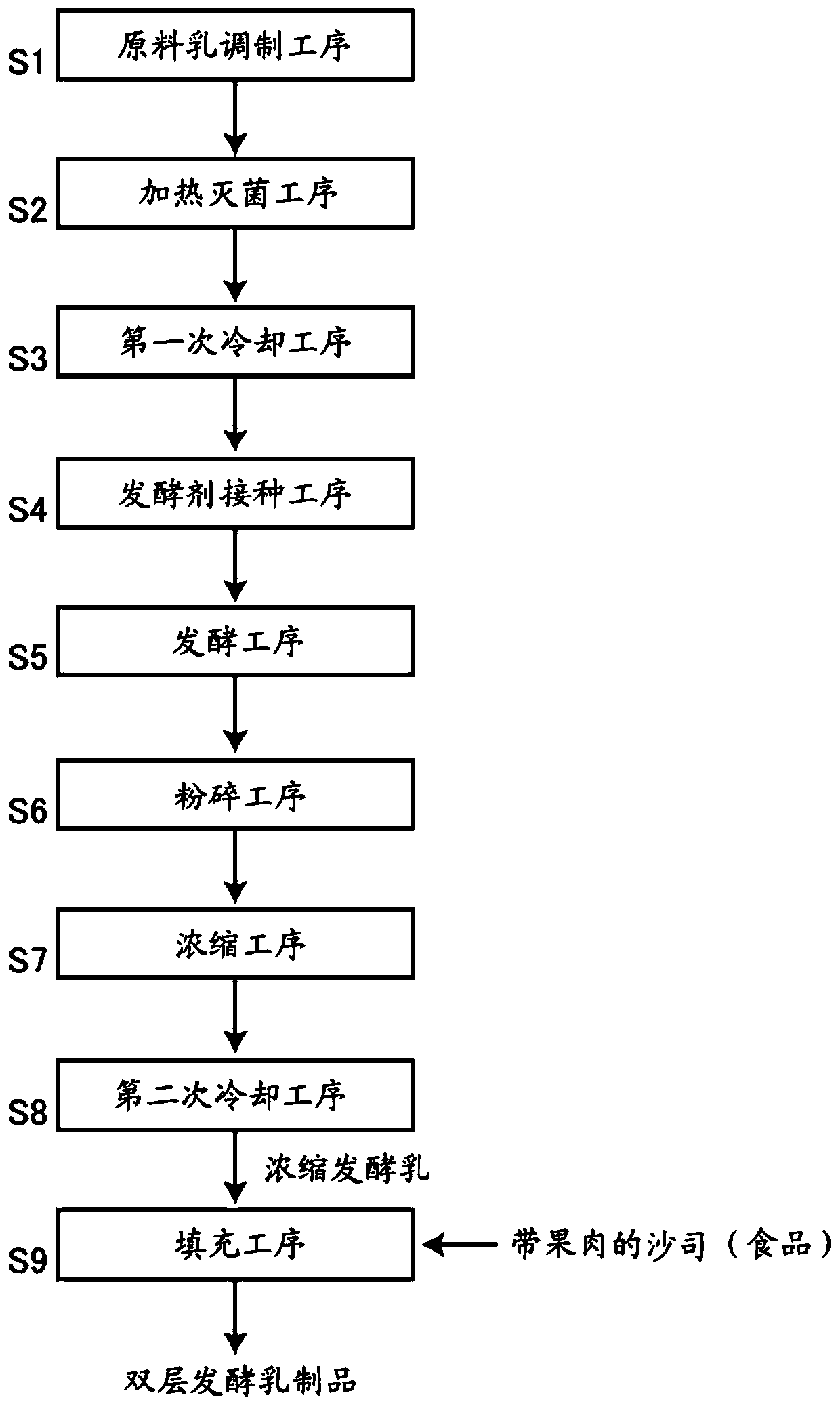

[0051]

[0052] according to figure 1 In the flowchart shown, concentrated fermented milk subjected to a concentration step (whey removal) after fermentation is prepared, and a double-layer fermented milk product is manufactured using the concentrated fermented milk. In the preparation of concentrated fermented milk, first, the raw material milk is mixed to obtain a preparation liquid whose composition is adjusted to account for 11.1% of total solid content, 0.1% of fat content, and 4.8% of protein, and the preparation liquid is prepared by using a continuous plate heat exchanger. Sterilize, cool to 43°C, inoculate a lactic acid bacteria starter, and ferment the preparation to a pH of 4.55. As the lactic acid bacteria starter, a starter mixed with bulgaricus and thermophilic bacteria was used. After the fermentation is completed, the fermented milk is stirred, the curd is crushed, and the whey (light liquid) is separated with a nozzle separator (KNA-3: manufactured by GEA W...

Embodiment 1-1

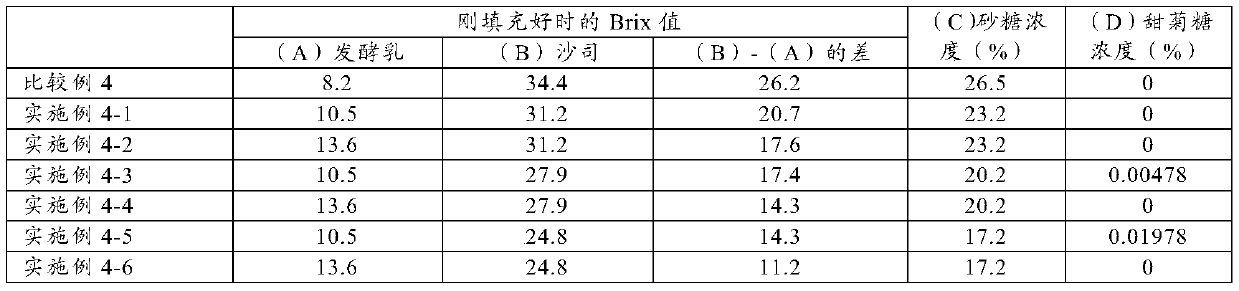

[0075] A fermented milk product prepared by filling the same concentrated fermented milk as above with blueberry sauce (Brix value: 26) was obtained, and it was stored overnight at 5°C. 21.2% of blueberry pulp, 0.3% of LM pectin with a degree of esterification of 35, 19.2% of sugar, and 0.045% of stevia were mixed in the blueberry sauce. When the fermented milk product left to stand overnight was supplied to the vibration tester, the interface between the sauce and fermented milk was slightly disturbed, but this was considered to be within the allowable range.

Embodiment 1-2

[0077] A fermented milk product prepared by filling the same concentrated fermented milk as above with blueberry sauce (Brix value: 26) was obtained, and it was stored overnight at 5°C. 21.2% of blueberry pulp, 0.5% of LM pectin with an esterification degree of 35, 19.2% of granulated sugar, and 0.045% of stevia were mixed in the blueberry sauce. When the fermented milk product left still overnight was supplied to the vibration tester, it was found that the interface between the sauce and fermented milk was hardly disturbed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com