A CFB boiler flue gas denitrification automatic control method and system

A technology for boiler flue gas and denitration, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of denitration control lag and denitrification agent consumption, etc., so as to reduce the original generation concentration of NOx and reduce the amount of denitrification agent. Consumption, the effect of solving the fluctuation of the peak-shaving denitrification control system of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

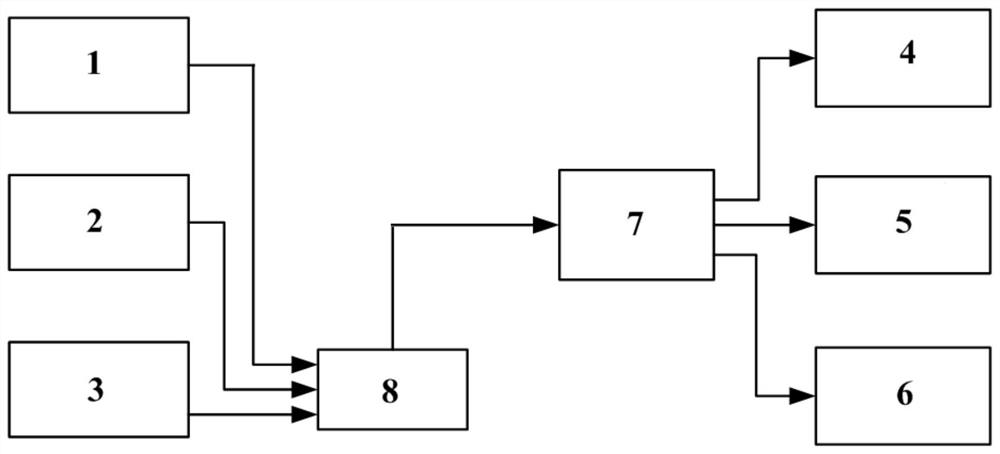

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] The CFB boiler flue gas denitrification automatic control method of the present invention comprises the following steps:

[0025] Measure the NOx concentration n(x) of the boiler flue gas in real time, and then compare the NOx concentration n(x) of the boiler flue gas with the theoretical value of the NOx concentration of the preset boiler flue gas n 0 (x) carry out normalization processing, obtain the normalization processing result of the NOx concentration of boiler flue gas;

[0026] When the normalized processing result of the NOx concentration of the boiler flue gas is in the interval [0, 0.75], calculate the consumption of the denitrification agent, where the consumption of the denitrification agent=k*(n(x)-n 0 (x))*m NH3 / m NOx *B1+B2, k is the flow coefficient, B1 is the flue gas flow rate of the boiler, B2 is the feed-forward data of denitrification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com