Robot hole-making error compensation device suitable for curved surface structures and method thereof

A robot hole making and error compensation technology, applied in manipulators, manufacturing tools, program control manipulators, etc., can solve the problem that the quality of robot hole making is difficult to meet the requirements of aviation hole making, etc., and achieve the rapid formation of closed-loop feedback, automation and integration. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

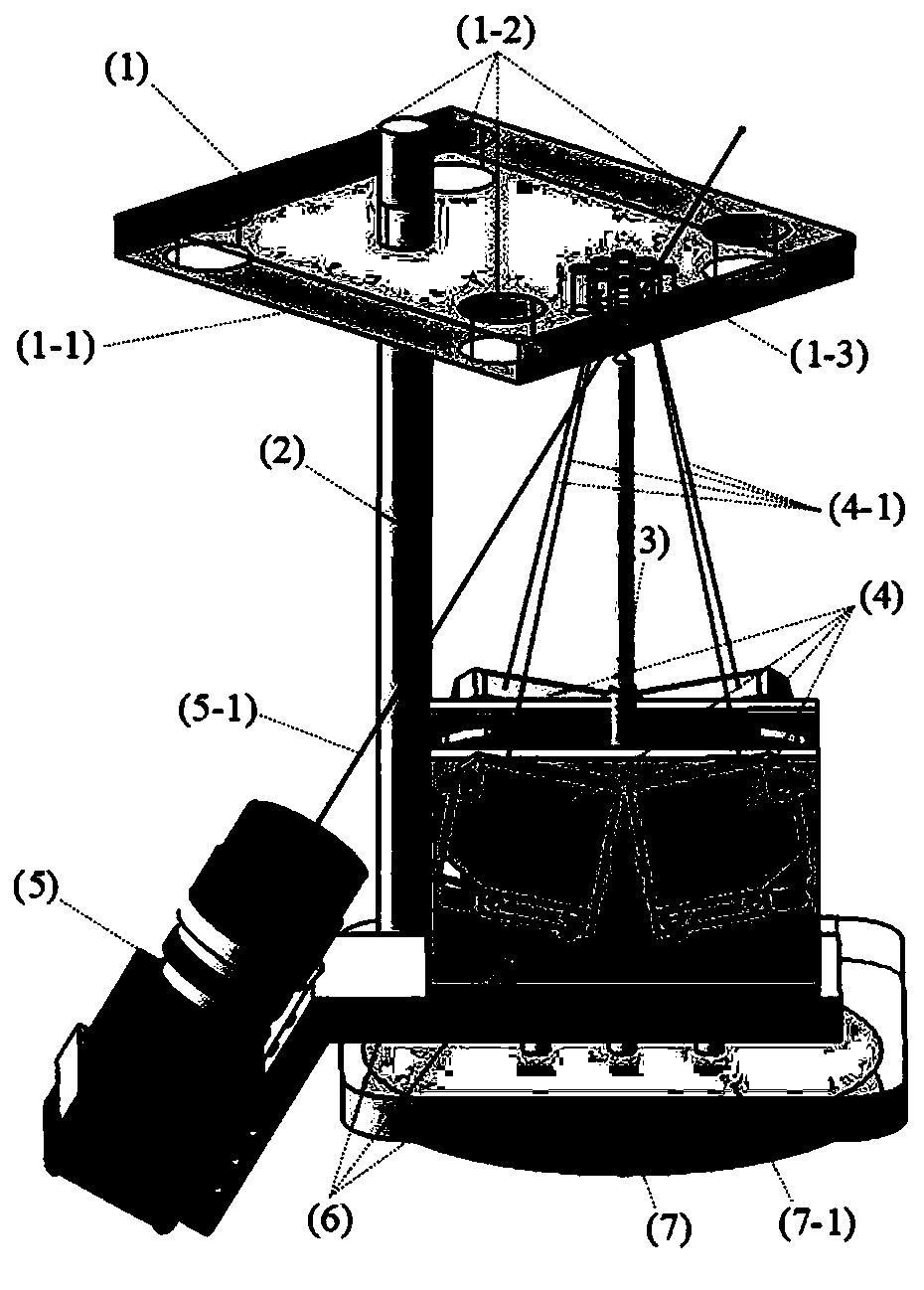

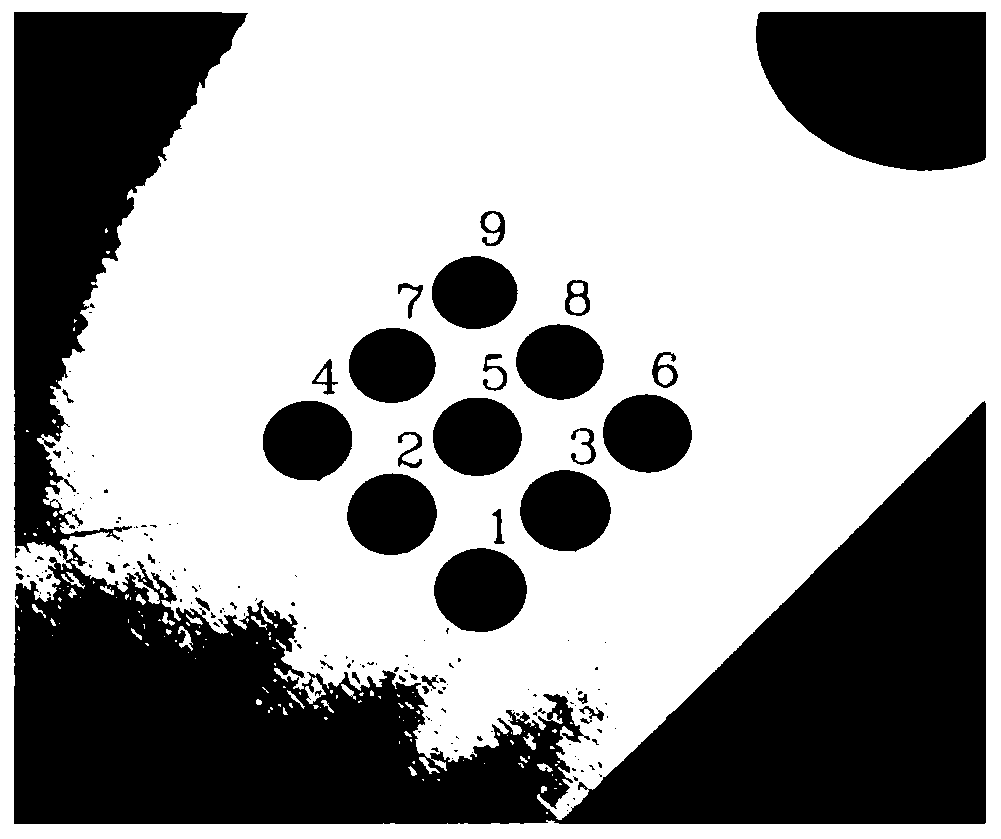

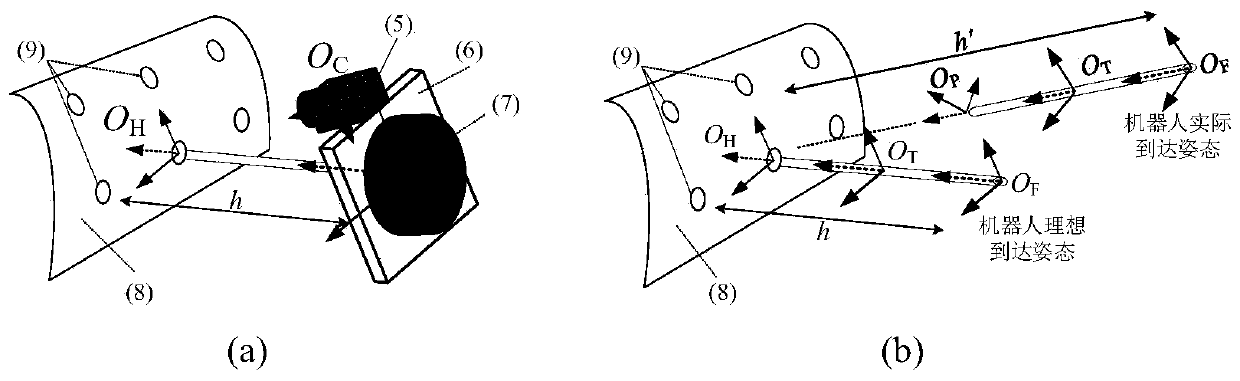

[0052] figure 1 Shown is a schematic diagram of a robot hole-making error compensation device suitable for curved surface structures of the present invention, that is, a schematic diagram of the installation of the end effector and the calibration plate of the present invention, wherein the end effector mainly includes a CCD industrial camera 5, four Laser ranging sensor 4, tool 3 and several fixtures 6. The industrial camera 5 is fixed to the end of the robot at a certain angle for detecting the position of the hole; four laser ranging sensors 4 are distributed around the tool 3 to measure the height and direction of the end of the robot relative to the surface of the part; the tool 3 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com