Chainless hollow hub bicycle

A technology for hollow hubs and bicycles, which is applied to two-wheeled bicycles, bicycles, bicycle accessories, etc., and can solve problems such as easy detachment, chain drop, dirty clothes, easy wear and corrosion of transmission parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

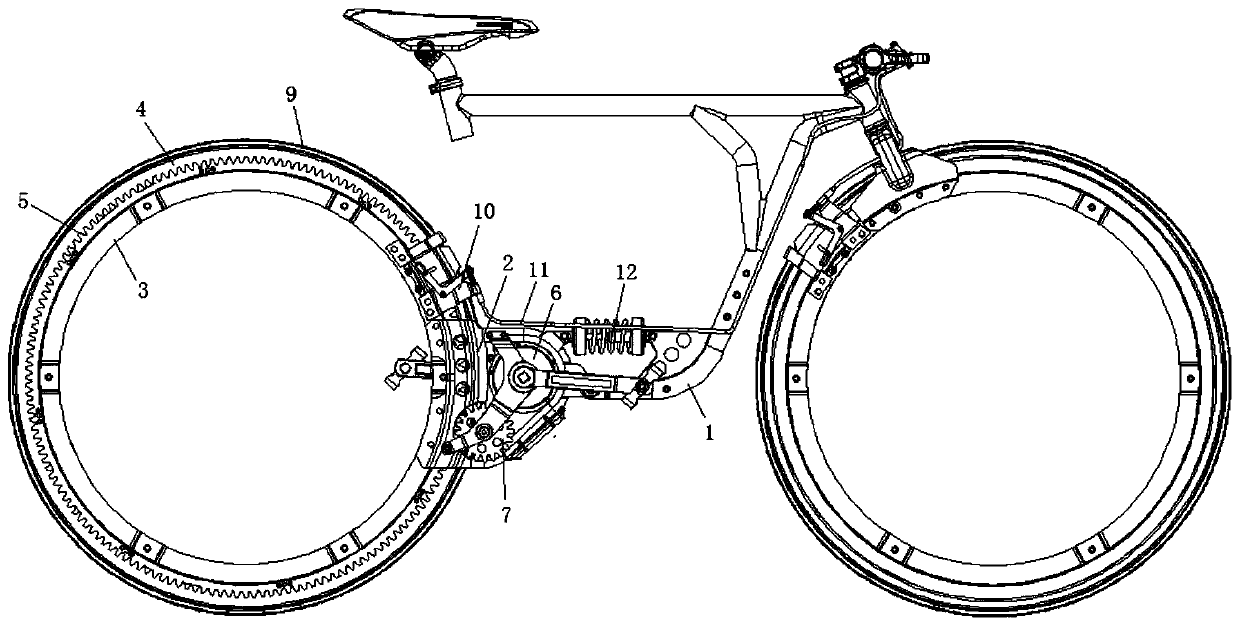

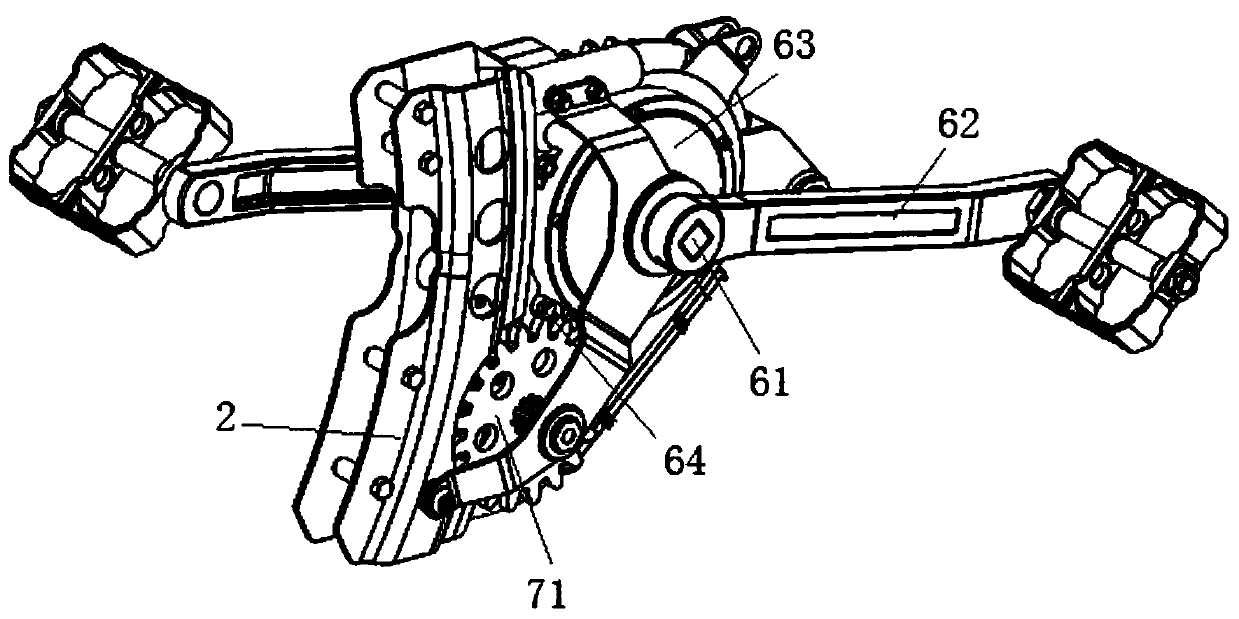

[0036] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , a chainless hollow hub bicycle provided in the embodiment of the present invention, such as figure 1 As shown, the bicycle includes a frame 1, and the frame 1 includes a connecting portion 2; a shock absorbing mechanism 12 may be connected between the frame 1 and the driving mechanism.

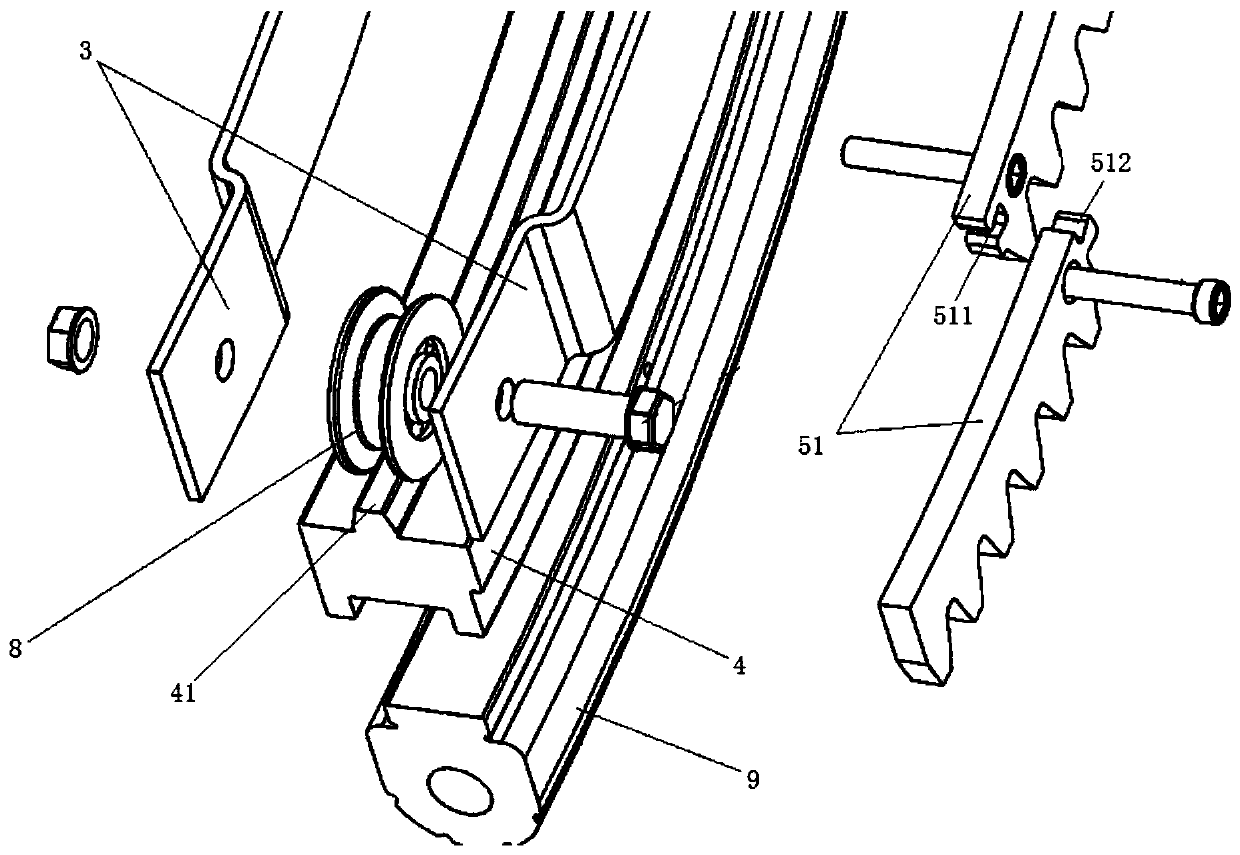

[0037] rear wheel mechanism, such as figure 2 As shown, the rear wheel mechanism includes a ring mount 3 and a hub 4 located outside the ring mount 3 and rotatably connected to the ring mount 3; the connecting portion 2 is fixed to the ring mount 3 One side of the hub 4 is fixedly connected with an outer ring gear 5; specifically, a plurality of V-shaped bearings 8 are hinged on the annular fixed frame 3, and a ring of convex rails 41 is arranged on the inner side of the hub 4, and each The V-shaped bearings 8 all abut against the protruding rails 41 to realize the rot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap