Repairing vehicle lifting scheme without affecting bridge floor traffic

A technology for overhauling vehicles and solutions, applied in bridge maintenance, bridges, bridge parts, etc., can solve the problems of casualties on the bridge deck, severe weather effects, hitting stay cables or slings, etc., to reduce social and economic costs. The effect of impact, wide applicability, strong practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

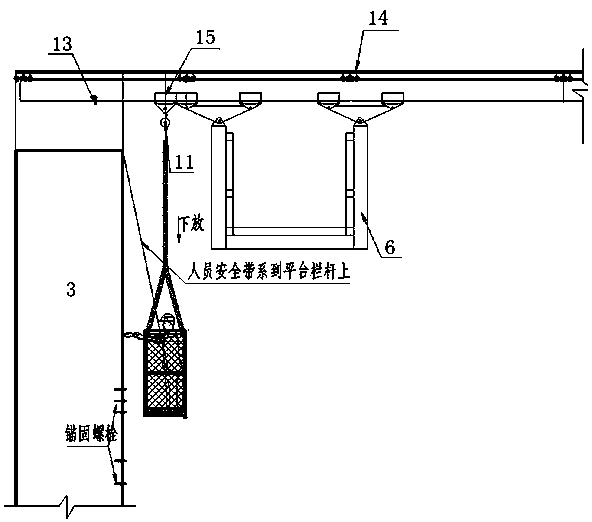

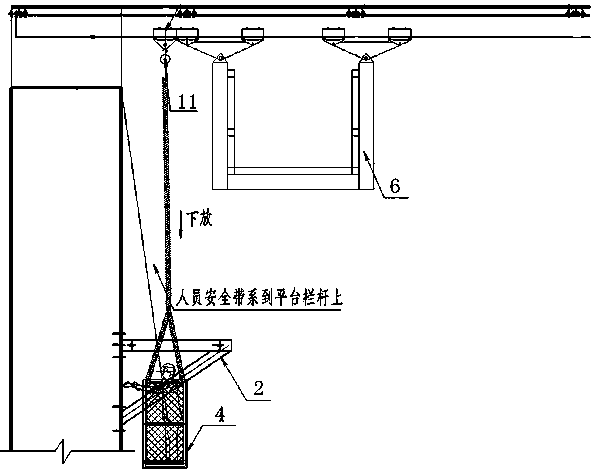

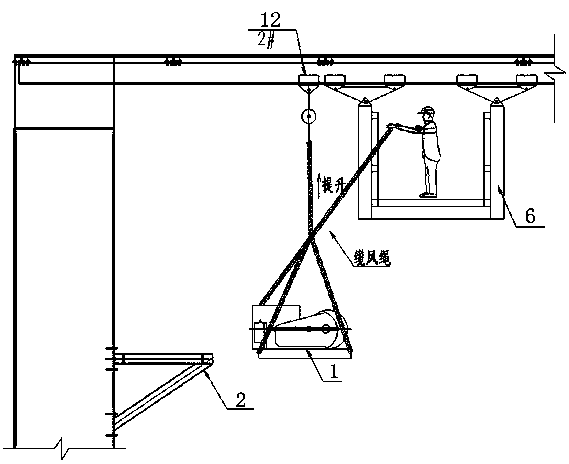

[0040] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0041] The winch platform 2 of the present invention is made up of two triangular trusses 19, the triangular truss 19 is welded by No. 16 I-beams, and the transverse connection system 20 between the two trusses is also welded by No. 16 I-beams. The trusses are connected by bolts, and the trusses are connected to the bridge pier 3 or the crossbeam by planting bars. The planting bar bolts are 8.8-grade M18 bolts, the planting bar depth is 27cm, and each triangular truss has 19 planting bars and 10 bolts.

[0042] The weight of the maintenance vehicle 5 is about 12T-15T. By setting 16 sets of movable pulleys on the track 13, the hoist 1 can be selected to be about 6T. The hoist 1 is equipped with hydraulic brakes and manual brakes, and has a sudden power failure. The parameters are as follows:

[0043]

[0044] A kind of maintenance vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com