Device for cleaning soil between piles of long screw pile-reinforced soft soil layer roadbed and cleaning method

A technology of a soft soil layer and a cleaning device, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of difficulty in controlling the shape and size of the cast-in-place pile cap, and the workload of manual cleaning of the soil between the piles is large, and achieves comprehensive construction. The effect of low cost, high construction efficiency and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

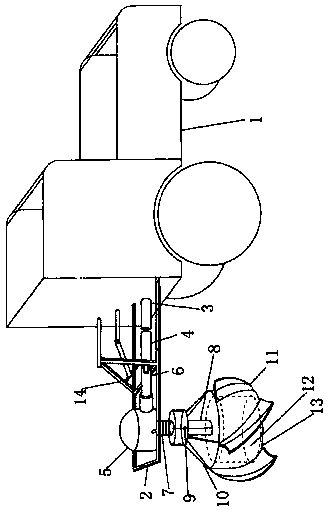

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

[0021] The invention discloses a method for clearing the soil between piles for strengthening and treating soft soil subgrades with long screw piles, which is characterized in that a device for cleaning the soil between piles is first assembled on site, and then the device is used for mechanized cleaning of the soil between piles.

[0022] The steps to assemble the soil cleaning device between piles on site are as follows:

[0023] The first step, according to the diameter of the pile head 12 of the long screw pile, process the sleeve 13 whose diameter is 2 cm larger than the diameter of the pile head 12, weld the spiral cutting blade 11 on the outer wall of the sleeve 13, Five helical cutting blades 11 are welded at equal intervals on the outer wall of the cylinder 13 to form an annular cutting soil cutterhead; the top of the sleeve 13 is welded to connect the conical frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com