Comb type double-layer parking garage

A double-layer parking, comb-type technology, applied in the field of living machinery, can solve the problems of large environmental damage in three-dimensional garages and underground efficiency of traditional garages, achieve high practicability and market value, solve large environmental damage, and increase safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

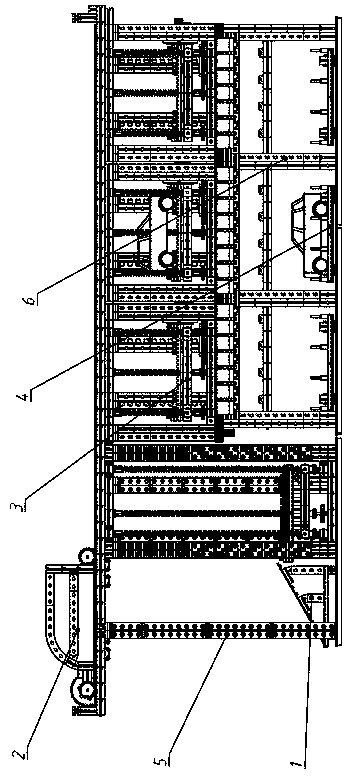

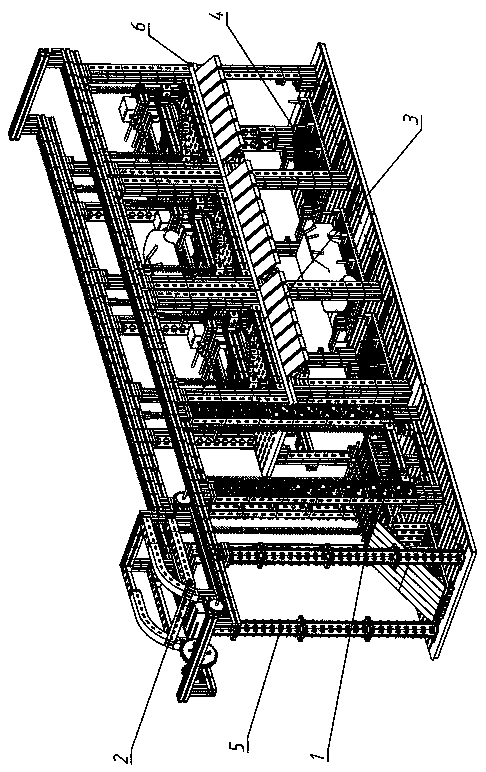

[0045] Embodiment 1: as Figure 1-2 As shown, a comb-shaped double-deck parking garage includes a lifting module 1, a lateral movement module 2, an inventory module 3, a parking space conversion module 4, a frame I5 and a frame II6; the lifting module 1 is installed in the frame I5, The inventory module 3 and the parking space conversion module 4 are installed in the frame II6, and the inventory module 3 is located above the parking space conversion module 4, and the traverse module 2 is installed on the upper part of the frame I5 and the upper part of the frame II6, and the frame I5 and The frame II6 is connected together; the lifting module 1 moves up and down in the frame I5 and cooperates with the traverse module 2 to realize the access of the car in the inventory module 3; the parking conversion module 4 is located on the first floor of the frame II6 for access car or electric vehicle.

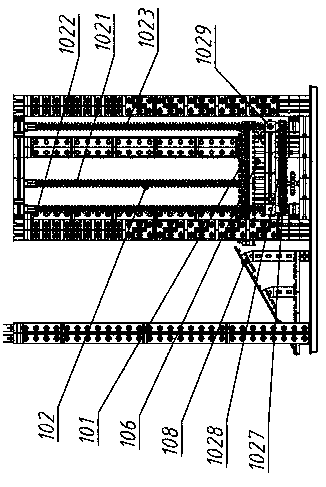

[0046] Specifically, the lifting module 1, such as Figure 3-5 As shown, it include...

Embodiment 2

[0059] Embodiment 2: A method for using a comb-shaped double-deck parking garage, including parking of cars on the second floor, parking of cars on the first floor and parking of electric vehicles on the first floor.

[0060] When the car on the second floor is parked, the car is smoothly driven into the undercarriage 106 of the lift module 1 by the bottom slope 108, and the whole garage is started by triggering the start switch after people leave the car.

[0061] The car rises on the A-type comb platform 101 with the lead screw lifting structure I102. When the A-type comb platform 101 triggers the upper limit switch, the motor I103 stops, and waits for the B-type comb platform 202 in the traverse module 2 to move on the rack 203. Move up and trigger the interactive position limit switch on the rack 203.

[0062] The B-type comb-tooth platform 202 pauses temporarily when it touches the interaction-related limit switch. At this time, the B-type comb-tooth platform 202 is direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com