System and method for three-dimensional detection of holes of concrete with cracks

A three-dimensional detection and concrete technology, applied in the direction of measuring device, mechanical measuring device, mechanical depth measurement, etc., can solve the problems of large influence of heat source, unrecognizable, mixing of diffraction signals, etc., and achieve strong operability and strong real-time performance , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] At present, the non-destructive testing techniques used mainly include ultrasonic method, infrared thermal imaging method, and ground radar method. These three methods all have a prerequisite, requiring researchers to have certain professional knowledge and understand the identification and analysis of waveforms or profiles. The shape and size of concrete voids cannot be obtained intuitively. The invention has a simple structure, and compared with the prior art, has the characteristics of low cost, strong real-time performance, high precision, easy operation and the like.

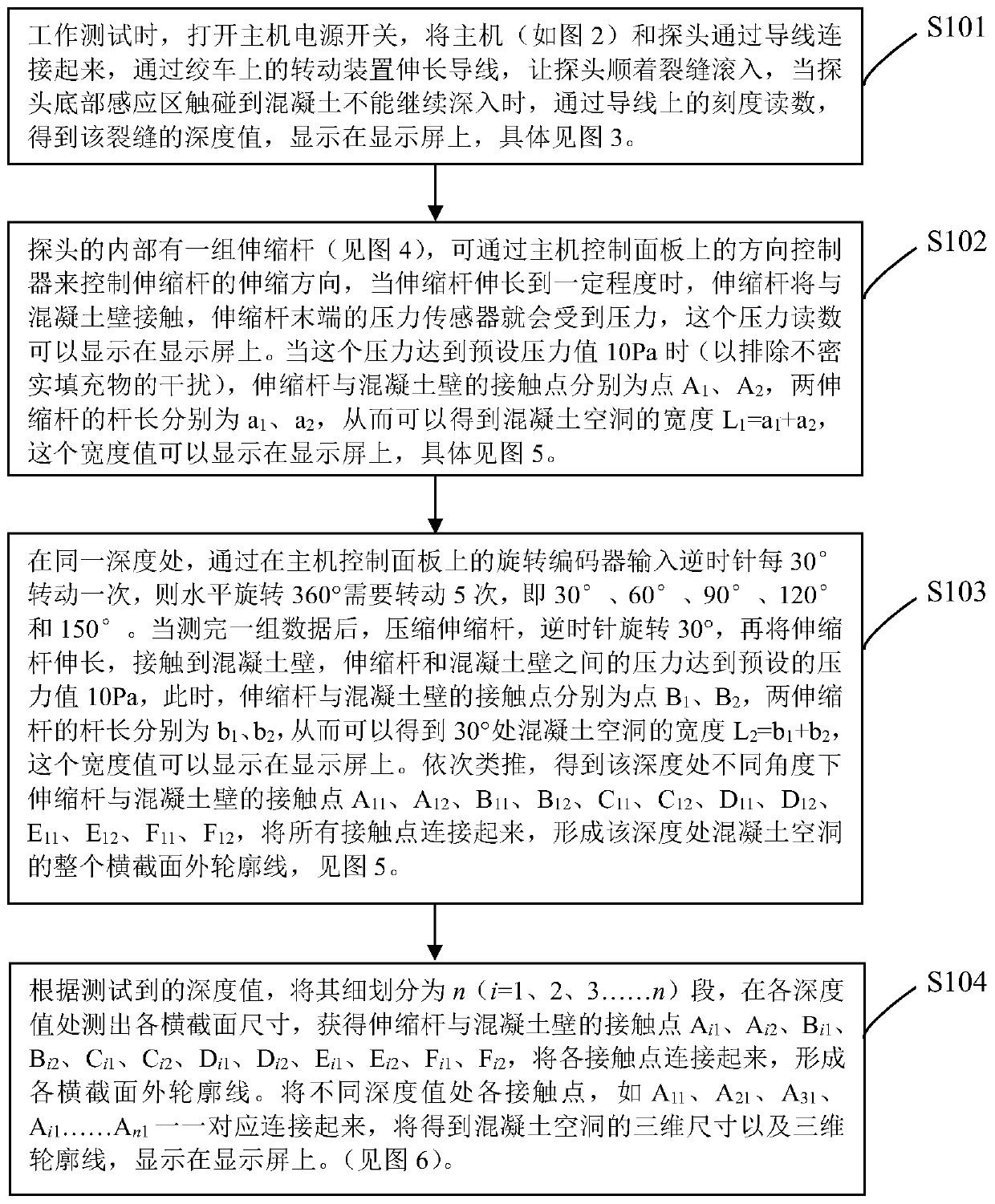

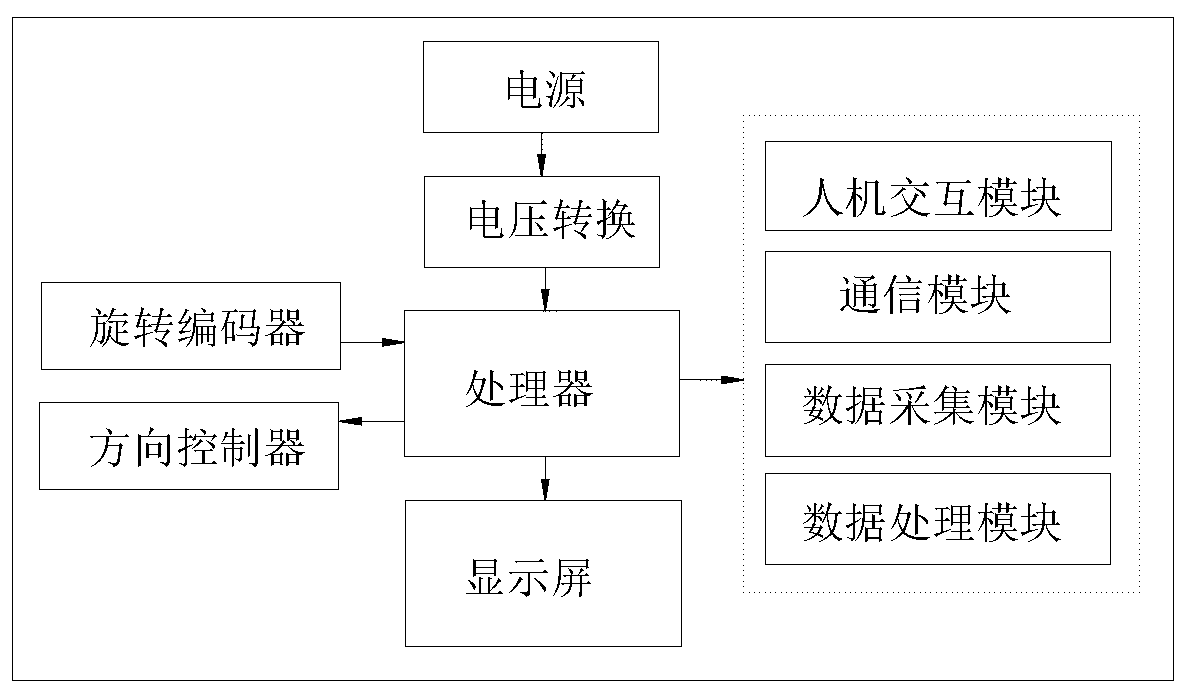

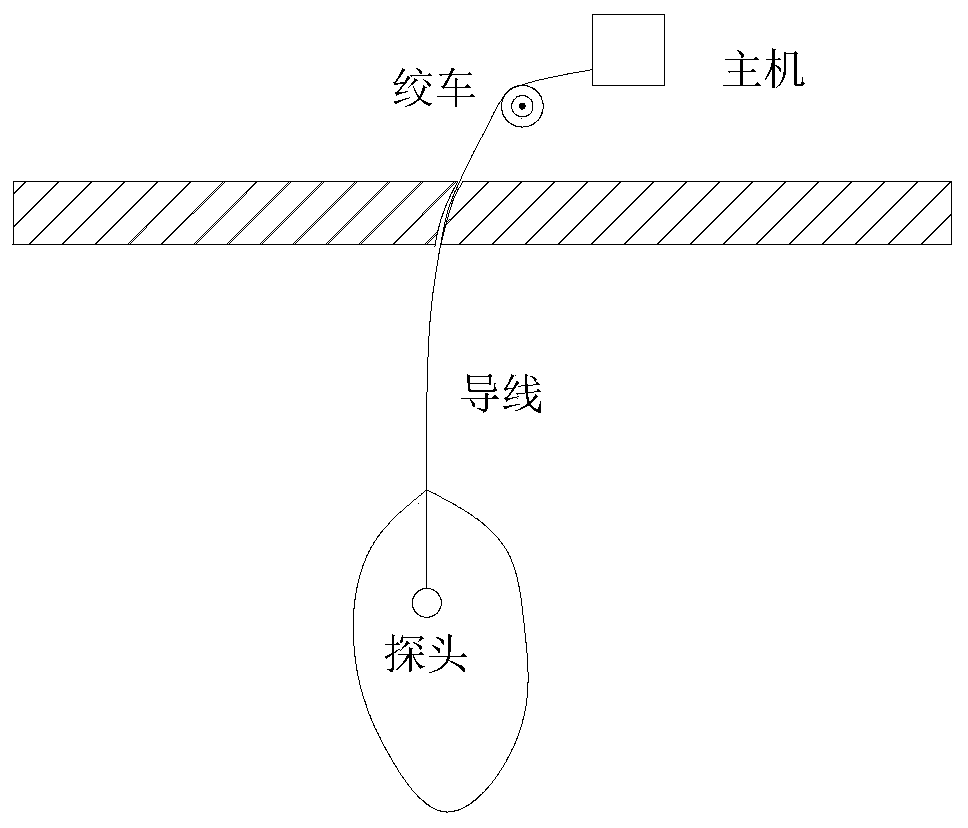

[0029] figure 1 , the three-dimensional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com