A kind of mask equipment process debugging method

A debugging method and mask technology, applied in the field of masks, can solve the problems of insufficient use of masks, waste efficiency and high cost, and achieve the effects of high detection and debugging efficiency, consistency assurance, and high use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] like Figures 1 to 2 As shown, a mask equipment process debugging method of the present invention includes the following steps:

[0032] (1) apply photoresist on the mask, and carry out photolithography exposure, development, and etching related procedures respectively to obtain corresponding graphics;

[0033] (2) compare the graphics obtained according to step (1) with the designed graphics, and debug the glue coating equipment, the lithography equipment, the developing equipment and the etching equipment respectively according to the errors of the two;

[0034]In step (1), before applying photoresist and photolithography exposure on the mask, the mask is evenly divided into several equidistant areas, such as the lateral area is A area, B area, C area...X area, etc., The vertical area is A1 area, A2 area, A3 area...A X area, etc., so that the whole is divided into several standard areas; then each area is divided into several areas to be tested, for example, in area ...

Embodiment 2

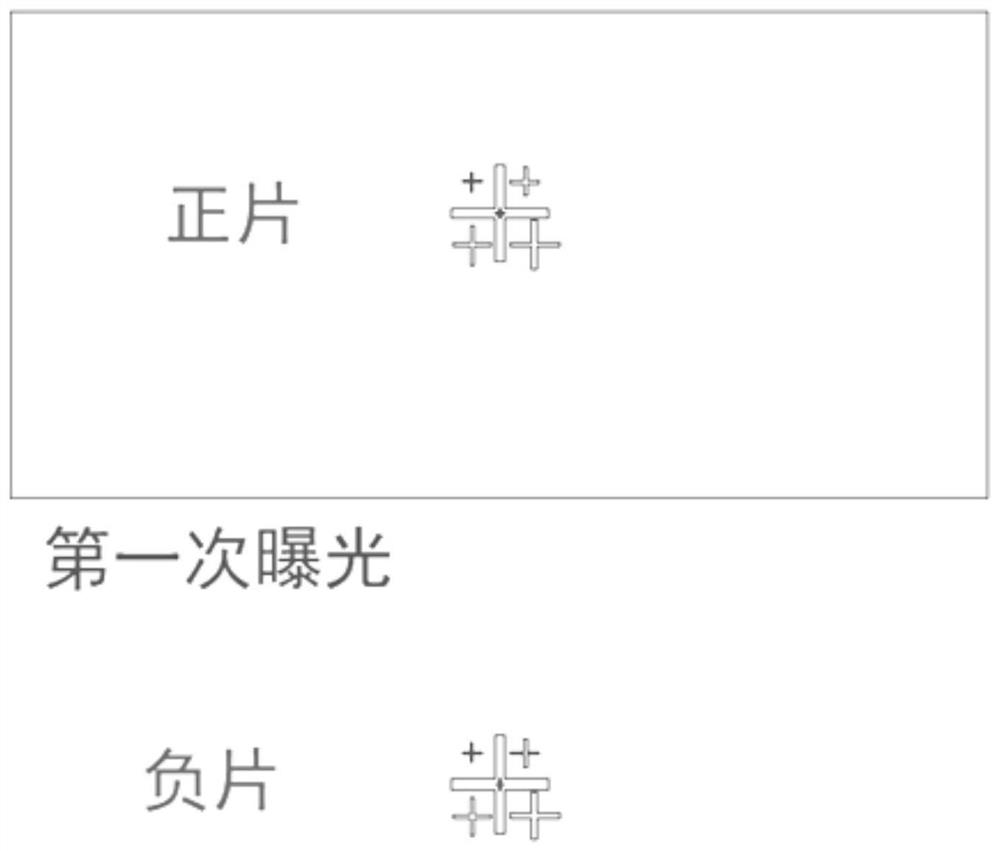

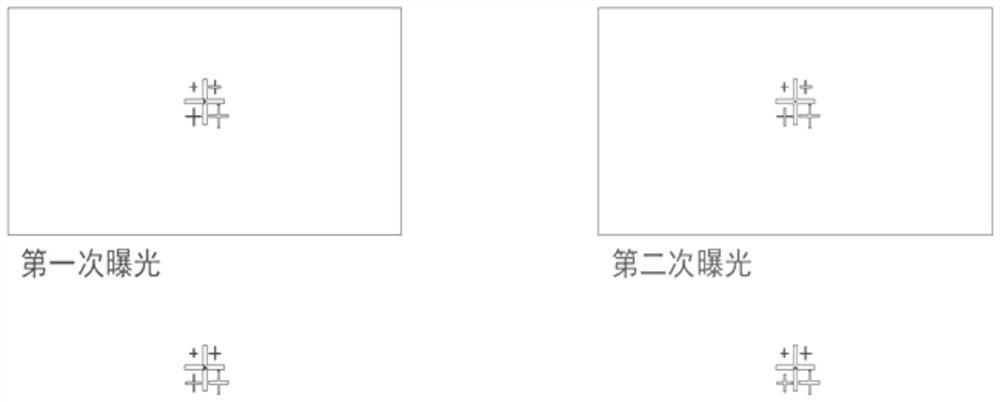

[0040] A process debugging method for mask plate equipment, on the basis of Embodiment 1, the graphics on the area to be tested of the mask plate are the same graphics in the same column and in two adjacent rows from top to bottom, and the graphics to be tested are the same graphics. The two adjacent rows of test areas on the same column and from top to bottom are the positive film area and the negative film area, and the positive film area and the negative film area are symmetrically distributed. After the first exposure, the exposure device was shifted by 500 μm during the second exposure.

Embodiment 3

[0042] A process debugging method for mask equipment, on the basis of Embodiment 2, the cross on each area includes a large cross and four small crosses, and the four small crosses are respectively located in the four areas divided by the large cross. The width of the leg of the big cross is 5 μm, and the width of the legs of the four small crosses are 1 μm, 2 μm, 3 μm, and 4 μm, respectively. The small cross of 1 μm is located in the upper left area of the intersection of the large cross, and the small cross of 2 μm is located at the upper right of the intersection of the large cross. Square area, the small cross of 3 μm is located in the lower left area of the intersection of the large cross, and the small cross of 4 μm is located in the lower right area of the intersection of the large cross. The cross is in the center of each area to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com