Industrial robot vibration suppression method

An industrial robot and vibration suppression technology, which is applied in the field of robotics, can solve problems such as increasing the energy consumption burden of robots, affecting robot motion, and increasing costs, and achieve the effects of reducing robot costs and production line system costs, avoiding continuous impact, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

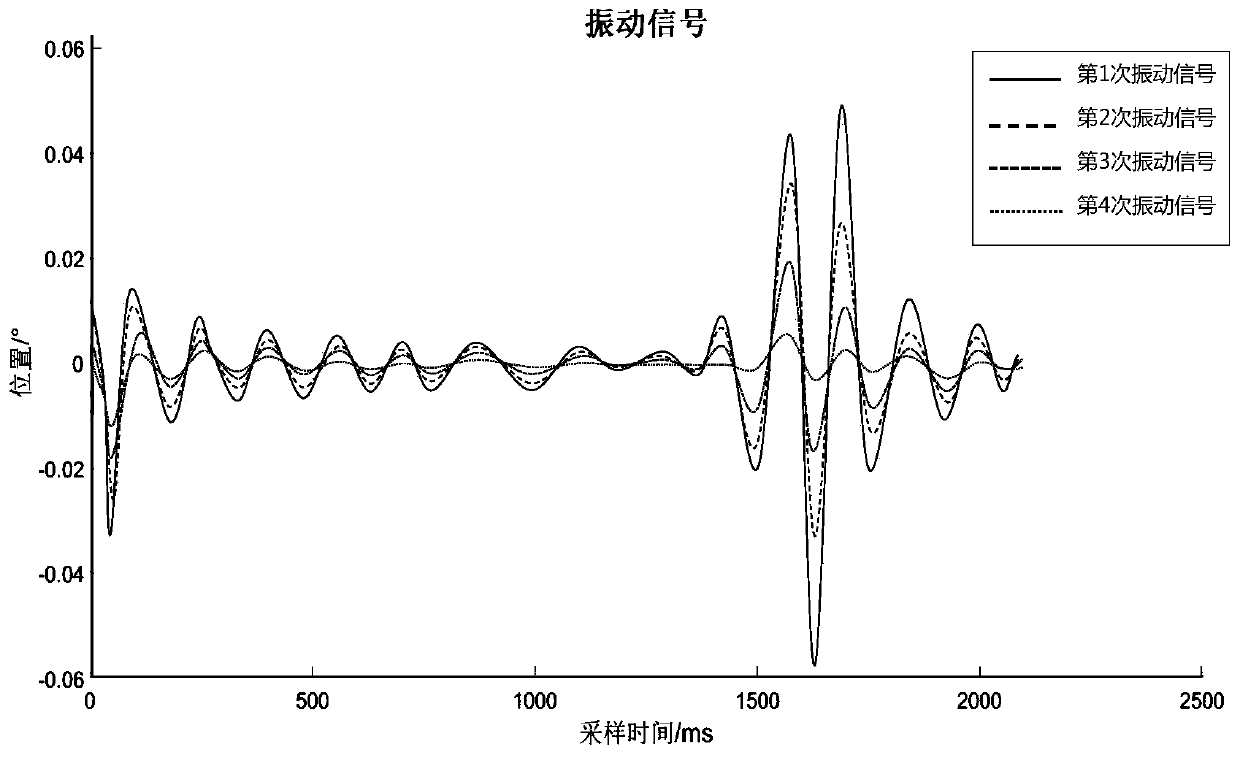

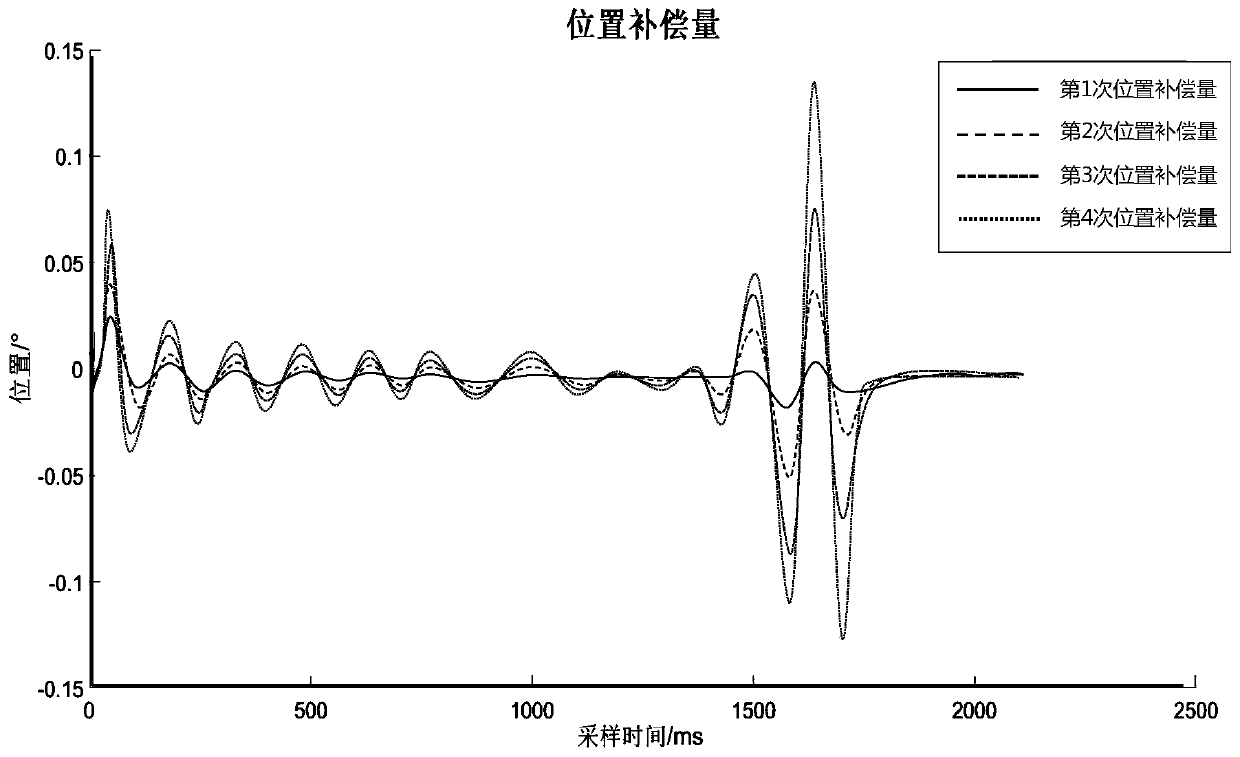

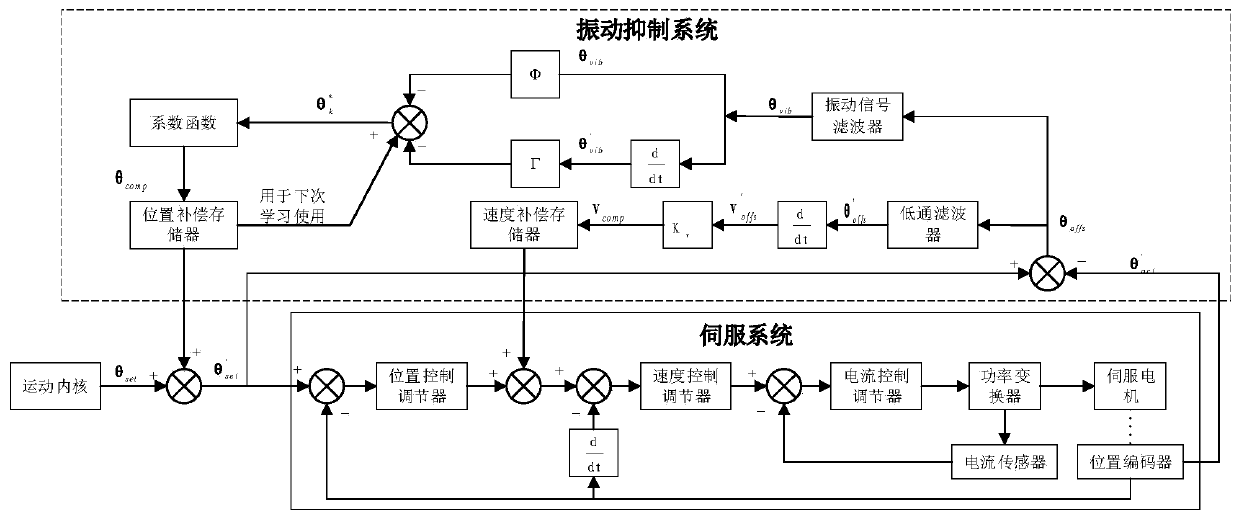

[0047]The purpose of the present invention is to provide a method for vibration suppression of industrial robots, by recording the given position and the actual position information fed back by the encoder by the control system in the process of recording the robot's action, and calculating the vibration suppression value according to the designed vibration suppression system The position compensation amount and the speed compensation amount, and finally add the position compensation amount to the given position and add the speed compensation amount by using the speed feedforward interface to realize the vibration suppression of the robot.

[0048] Hereinafter, a robot vibration suppression system according to an embodiment of the present invention will be described with reference to the drawings. figure 1 A configuration diagram showing a robot vibration suppression system according to an embodiment of the present invention.

[0049] The motion kernel performs kinematics plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com