Metal powder paint preparation device

A metal powder and coating technology, applied in the field of metal powder coating preparation equipment, can solve the problems of easy sticking of stirring paddles and pot walls, and achieve the effect of avoiding sticking and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

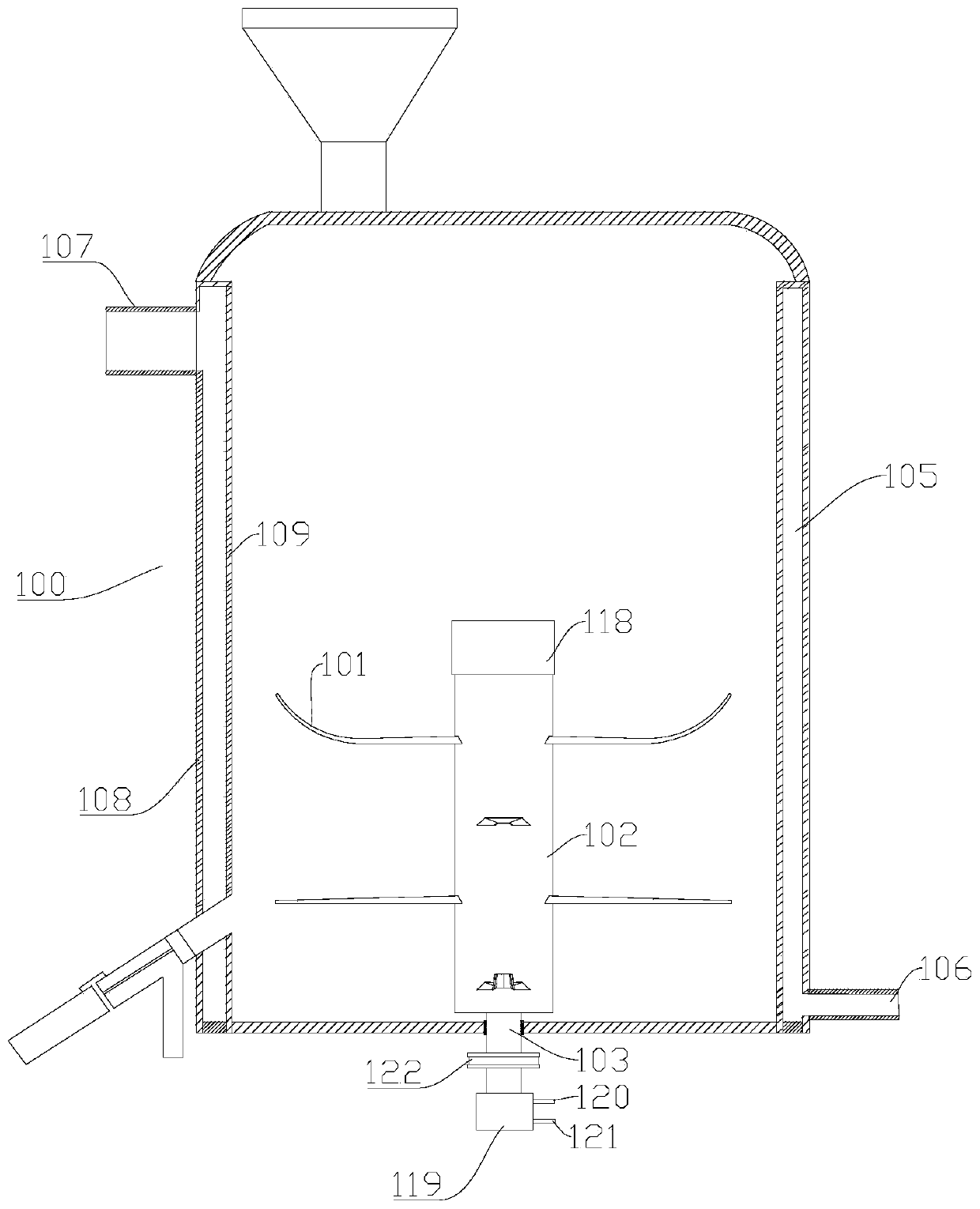

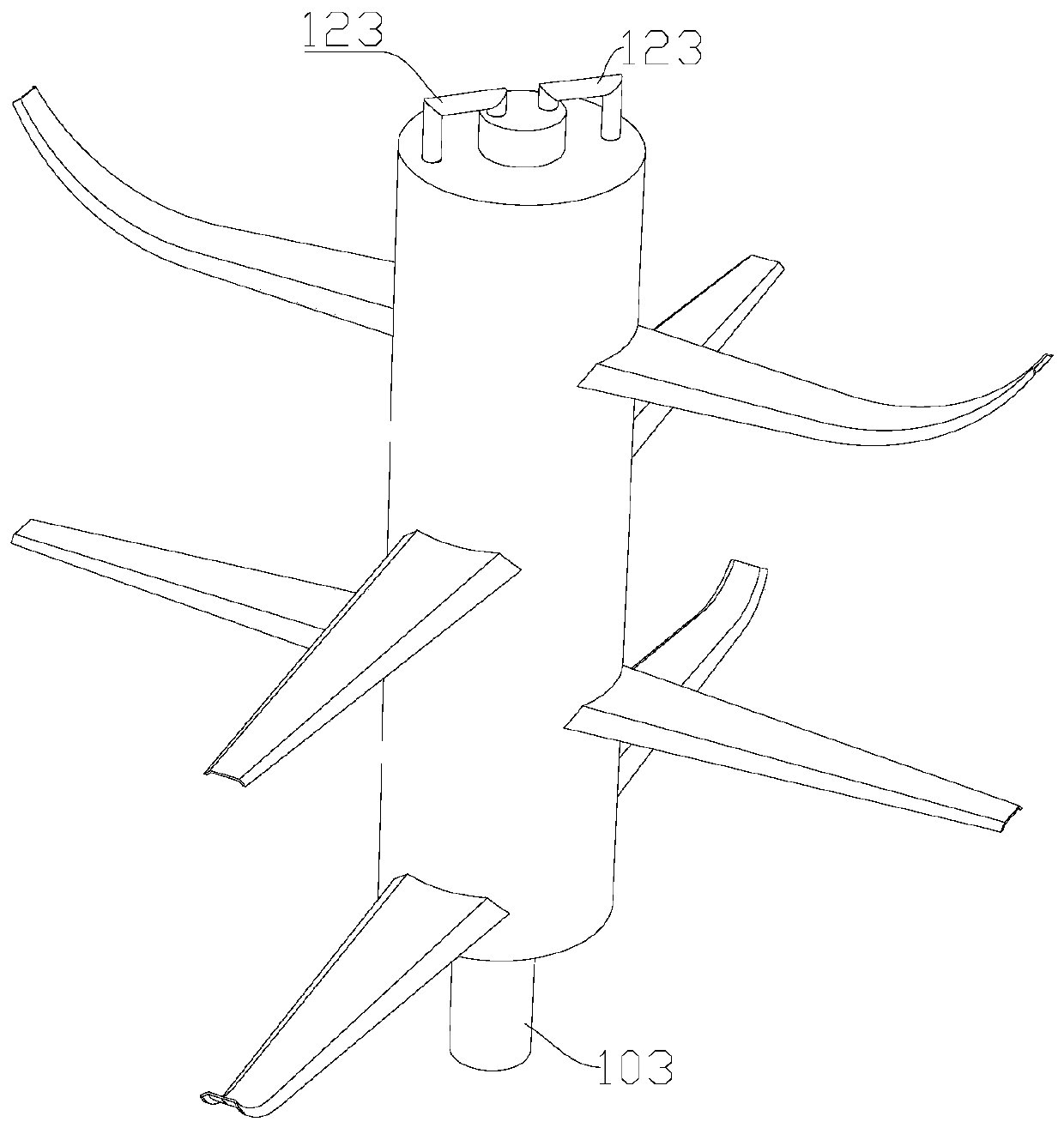

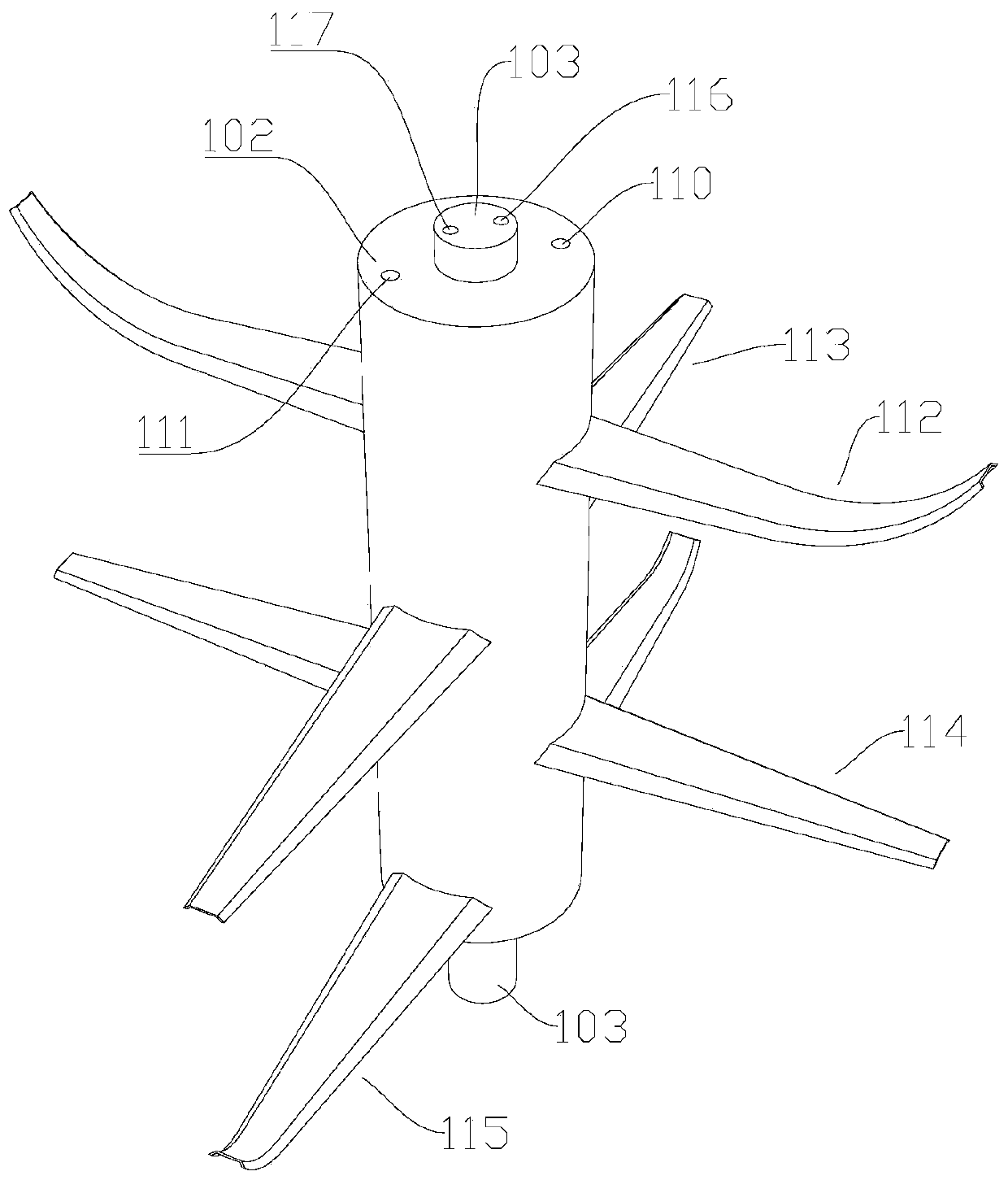

[0032] see Figure 1 to Figure 6 As shown, the embodiment of the present invention provides a metal powder coating preparation equipment, which includes a pot body 100 and a stirring paddle, the stirring paddle is used to stir the materials put into the pot body 100; the pot body 100 has a hollow cavity 105 , used to pass into the circulating liquid; the stirring paddle includes a paddle 101, and the paddle 101 has a blade flow channel 104, used to pass into the circulating liquid. The metal powder coating preparation equipment may be a bonding machine. The circulating liquid can be water or other cooling liquids. The paddle 101 of the stirring paddle is located in the pot body 100 . The metal powder coating can be an imitation chrome-plated mirror silver powder coating, and the metal powder coating preparation equipment can be used for preparing the imitation chrome-plated mirror silver powder coating.

[0033] The metal powder coating preparation equipment that this embod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap