An improved ABR reaction device and start-up method for suppressing acidification

A reaction device and improved technology, applied in the field of improved ABR reaction device, can solve the problems of slow growth of anaerobic microorganisms, long anaerobic start-up time, uneven influent water quality, etc., so as to facilitate absorption and utilization and shorten start-up Time, the effect of avoiding the influence of microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The waste water produced in the sorbic acid decomposition and purification process of a food additive company is treated by an improved ABR reaction device of the present invention that suppresses acidification. The influent indicators before treatment are COD>60000mg / L, BOD1000mg / L. After anaerobic biochemical treatment, the effluent index meets the requirements of aerobic process, that is, COD≤5000mg / L, BOD>1800mg / L, B / C ratio>0.35, SS<200mg / L, pH value 6.5-8.5.

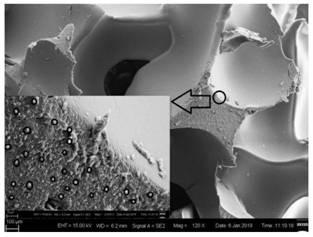

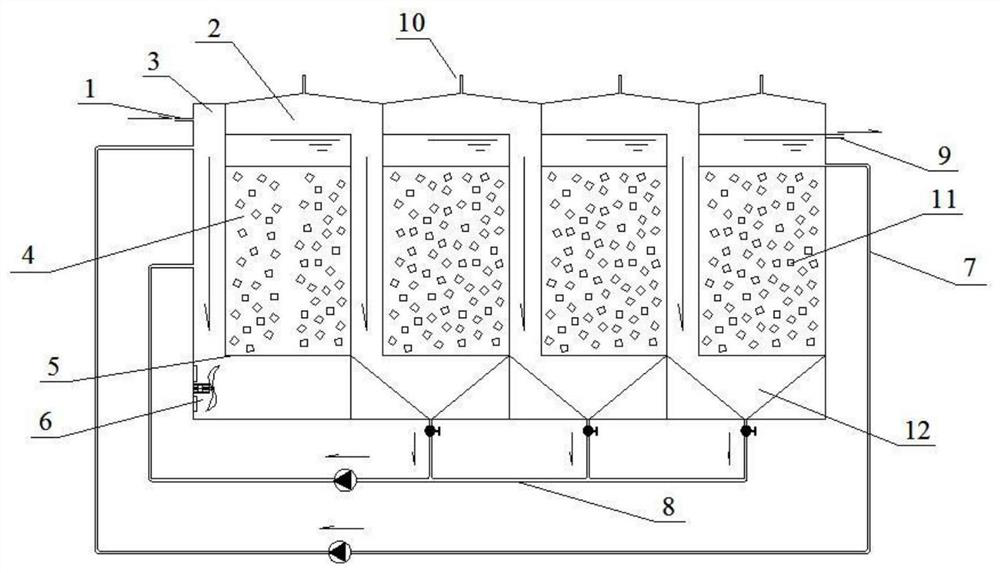

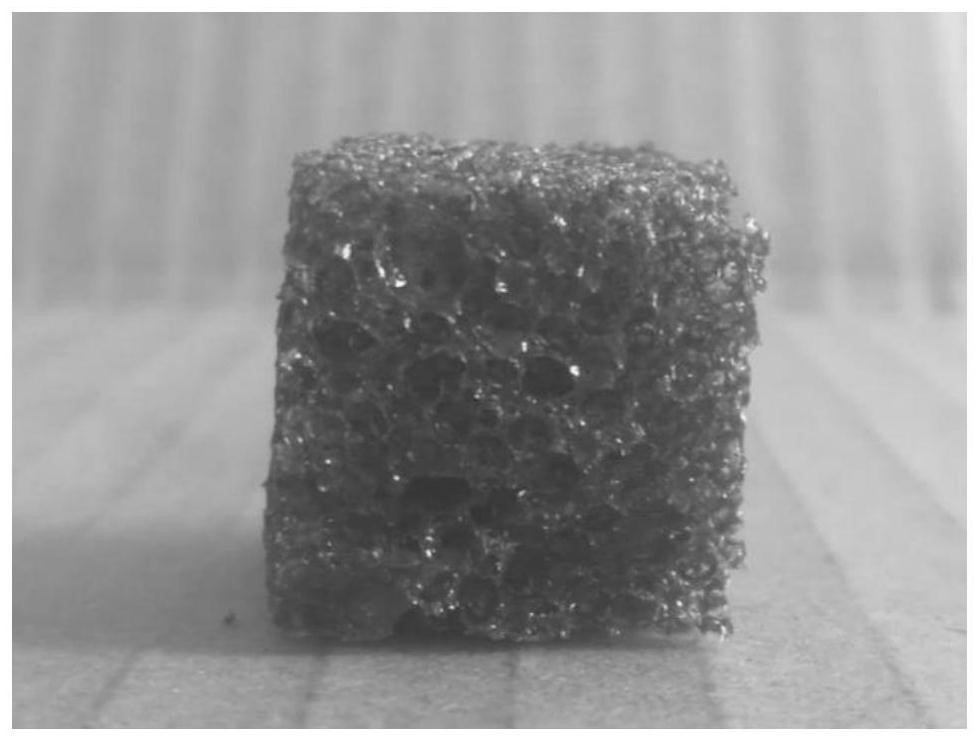

[0047] As shown in the figure, an improved ABR reaction device for suppressing acidification is composed of 4 compartments, each compartment includes an upward flow cell and a downward flow cell, and an upward flow cell and a downward flow cell. The volume ratio of the cells is 4:1, wherein the upward flow cells are equipped with suspended fillers, and the suspended fillers are covered with fixed grids. There is a stirring device in the downward flow grid chamber of the first compartment, a return pipe in t...

Embodiment 2

[0066] The molasses alcohol wastewater of a sugar factory is treated by an improved ABR reaction device of the present invention that suppresses acidification. The experimental water is molasses alcohol wastewater from a sugar factory in Guangxi. The main water quality parameters are shown in the table below.

[0067] Table of properties of molasses alcohol wastewater

[0068]

[0069] As shown in the figure, an improved ABR reaction device for suppressing acidification is composed of 4 compartments, each compartment includes an upward flow cell and a downward flow cell, and an upward flow cell and a downward flow cell. The volume ratio of the cells is 4:1, wherein the upward flow cells are equipped with suspended fillers, and the suspended fillers are covered with fixed grids. There is a stirring device in the downward flow grid chamber of the first compartment, a return pipe is provided in the end compartment, and an air duct is provided on the upper part of each compart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com