Preparation method of high-dielectric-performance polymer-based composite microporous material

A technology of microporous materials and composite materials, which is applied in the field of preparation of polymer-based composite microporous materials with high dielectric properties. It can solve the problems of difficult control of the dielectric constant of composite materials, internal defects affecting the comprehensive performance of composite materials, and poor dispersion. , to achieve the effects of reduced cell size, low dielectric loss, and increased cell density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a high dielectric performance polymer-based composite microporous material of the present invention, specifically comprising the following steps:

[0028] Step 1, use γ-aminopropyltriethoxysilane (AMEO) to modify the surface of hydroxylated multi-walled carbon nanotubes (MWCNT-OH), centrifuge wash and freeze-dry to obtain γ-aminopropyltriethoxy Modified multi-walled carbon nanotubes (AMEO-MWCNT) with base silane, dispersed the obtained AMEO-MWCNT in deionized water, added dropwise hydrochloric acid solution to adjust the pH to 4, and obtained positively charged AMEO-MWCNT (γ-aminopropyltri Ethoxysilane modified multi-walled carbon nanotube) aqueous dispersion;

[0029] Step 2, using the improved Hummers method to prepare graphene oxide (GO), dispersing the resulting GO into deionized water, and ultrasonically dispersing to obtain a negatively charged GO aqueous dispersion;

[0030] Step 3: Add the dispersion obtained in Step 1 and Step 2 into the...

Embodiment 1

[0036] The PEI / GO-e-MWCNT composite sheet with GO-e-MWCNT content of 0.5 wt% was placed in an autoclave, heated and fed with supercritical CO 2 fluid that makes CO 2 Diffuse into the PEI / GO-e-MWCNT composite sheet, the saturation temperature is 30°C, the saturation pressure is 10MPa, the saturation time is 12h, and a uniform composite / CO 2 Hybrid sheet, composite / CO 2 The mixed sheet was quickly transferred to a constant temperature silicone oil bath for foaming. The foaming temperature was 180°C, and the foaming time was 40s. Finally, it was placed in an ice-water bath to cool and shape to obtain polyetherimide / graphene oxide-wrapped carbon nanotubes. Composite microporous materials. Obtain the apparent density of gained composite microporous material after measurement is 950kg / m 3 , the cell size is 0.82 μm, and the cell density is 2.60×10 12 piece / cm 3 , the dielectric constant is 5.71, and the dielectric loss is 0.003.

Embodiment 2

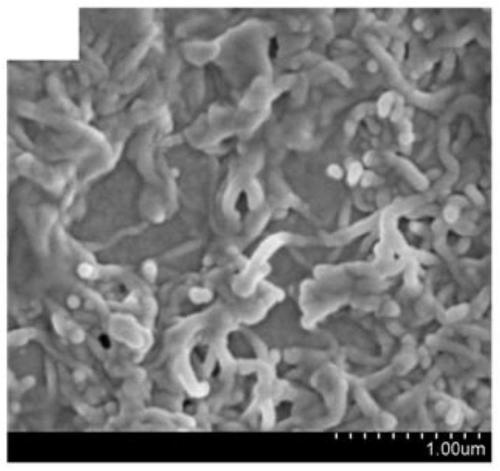

[0038] A PEI / GO-e-MWCNT composite sheet with 2 wt% GO-e-CNT content was placed in an autoclave, heated and fed with supercritical CO 2 fluid that makes CO 2 Diffuse into the PEI / GO-e-MWCNT composite sheet, the saturation temperature is 50°C, the saturation pressure is 12MPa, the saturation time is 12h, and a uniform composite / CO 2 Mix sheets. Composites / CO 2 The mixed sheet was quickly transferred to a constant temperature silicone oil bath for foaming. The foaming temperature was 200°C and the foaming time was 25s. Finally, it is placed in an ice-water bath to cool and set the shape to obtain a polyetherimide / graphene oxide-wrapped carbon nanotube composite microporous material. The apparent density that obtains gained composite microporous material after measurement is 529kg / m 3 , the cell size is 0.96 μm, and the cell density is 4.33×10 12 piece / cm 3 , the dielectric constant is 10.62, and the dielectric loss is 0.032. The SEM image of the PEI / GO-e-MWCNT composite mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Cell size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com