A kind of polypropylene/metal hydroxide/rare earth compound flame retardant material

A technology of rare earth compounds and hydroxides, which is applied in the field of polypropylene/metal hydroxide/rare earth compound flame retardant materials, to delay the degradation process, improve the vertical combustion level, and suppress violent combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

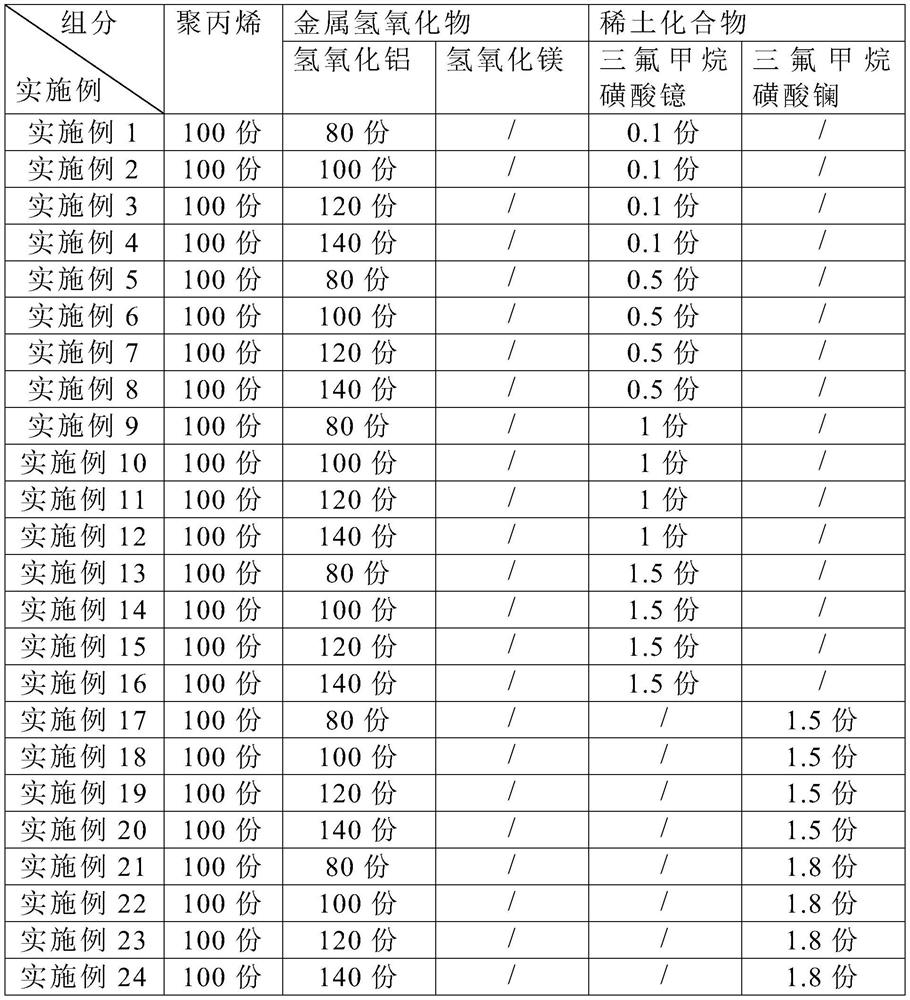

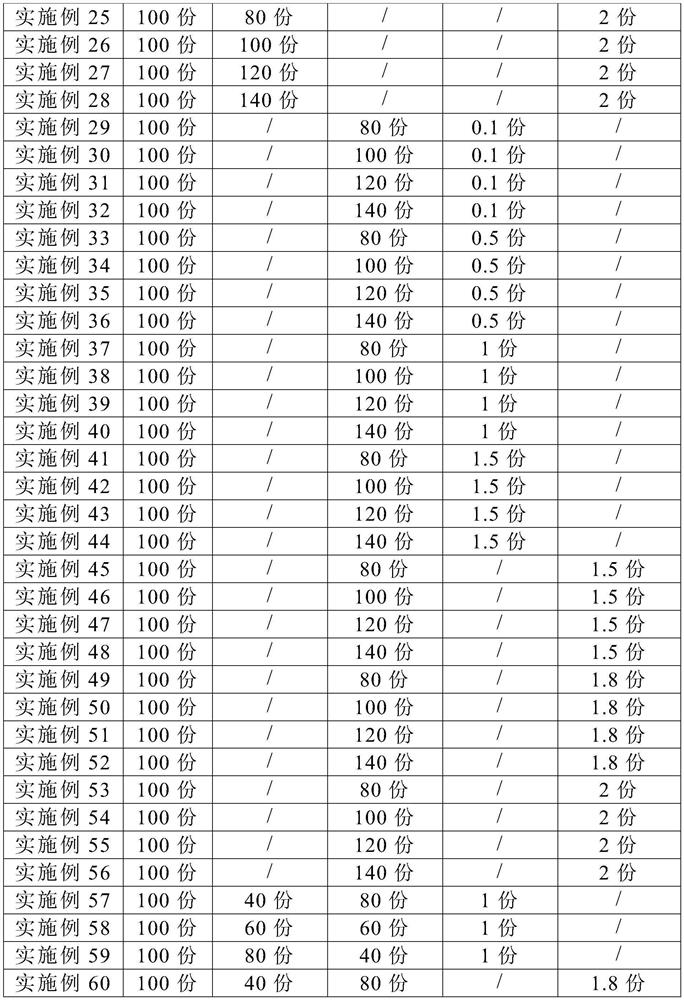

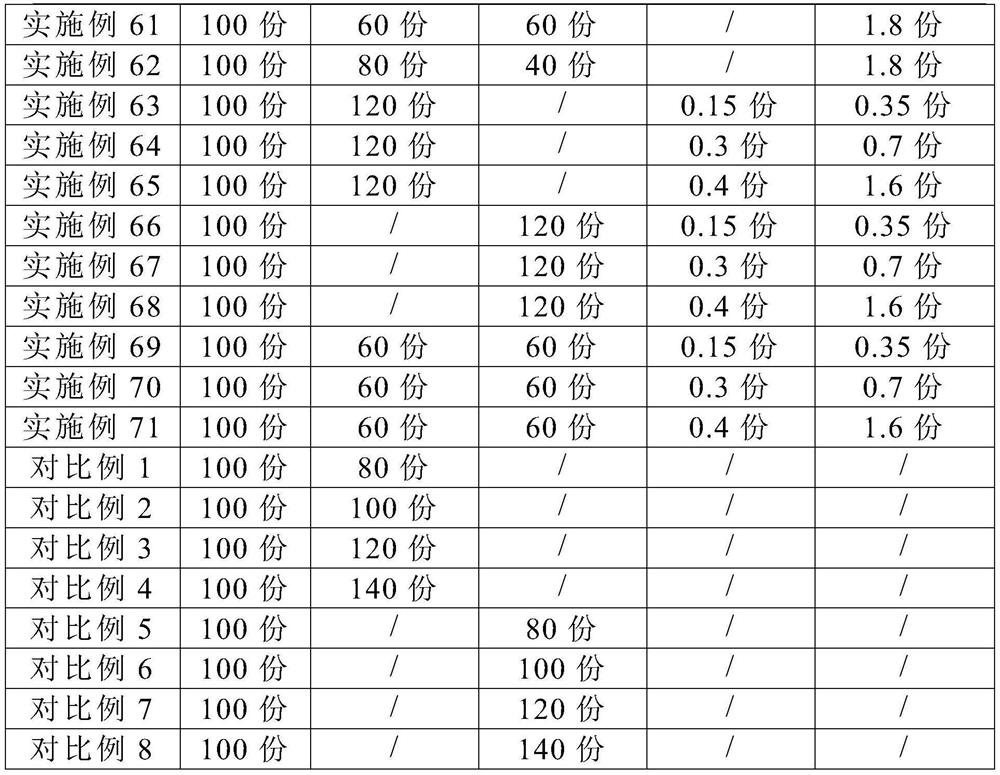

Embodiment 1-71

[0032] According to the polypropylene, metal hydroxide and rare earth compound in Example 1-71 of Table 1 respectively; the metal hydroxide was first dried in an oven at 80°C for 5 hours, then polypropylene was added and stirred to obtain a polypropylene / metal hydroxide mixture ;

[0033] Add 50% of the polypropylene / metal hydroxide mixture to the torque rheometer for melt blending, then add the rare earth compound, then add the remaining 50% of the polypropylene / metal hydroxide mixture, after the addition is complete, add The rotation speed was adjusted to 60r / min, and the processing was continued for 9 minutes, and the processing temperature was maintained at 180°C throughout the whole process to obtain a polypropylene / metal hydroxide / rare earth compound flame-retardant material.

Embodiment 72

[0035] The only difference from Example 1 is that in Example 72, the metal hydroxide was first dried in an oven at 60°C for 8 hours, then polypropylene was added and stirred to obtain a polypropylene / metal hydroxide mixture;

[0036] Add 40% polypropylene / metal hydroxide mixture to the torque rheometer to make it melt and blend, then add the rare earth compound, then add the remaining polypropylene / metal hydroxide mixture, adjust the speed after the addition is completed to 70r / min, and then processed for 6 minutes, the processing temperature was maintained at 190°C throughout the process, and a polypropylene / metal hydroxide / rare earth compound flame-retardant material was obtained.

Embodiment 73

[0038] The only difference from Example 1 is that in Example 73, the metal hydroxide was first dried in an oven at 90°C for 2 hours, then polypropylene was added and stirred to obtain a polypropylene / metal hydroxide mixture;

[0039]Add 60% polypropylene / metal hydroxide mixture to the torque rheometer to make it melt and blend, then add the rare earth compound, then add the remaining polypropylene / metal hydroxide mixture, adjust the rotation speed after the addition is completed to 50r / min, and then processed for 12min, the processing temperature was maintained at 160°C throughout the process, and a polypropylene / metal hydroxide / rare earth compound flame-retardant material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com