A kind of molecular sieve coating film and preparation method thereof

A molecular sieve and coating technology, applied in the direction of coating, etc., can solve the problems of lower product yield, low tensile strength of aluminum foil, easy to tear, etc., and achieve the effect of improving efficiency, increasing adhesion, and improving hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

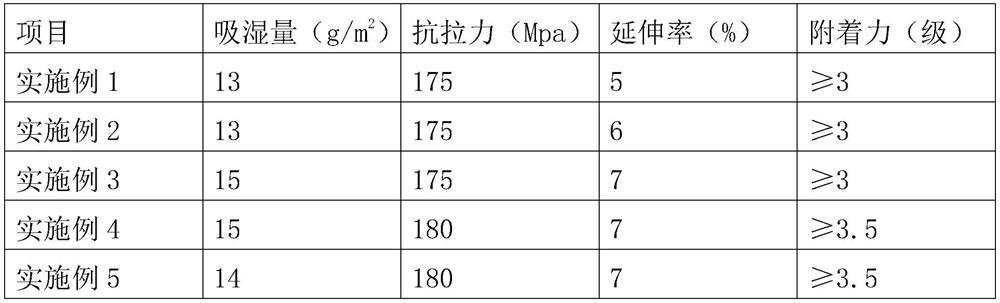

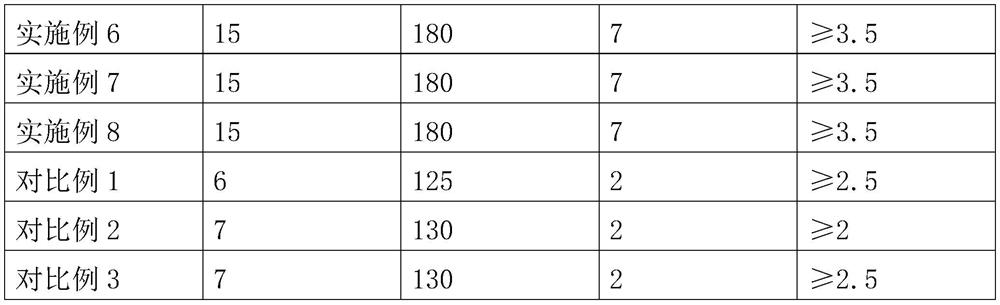

Examples

preparation example Construction

[0057] Correspondingly, the present invention also provides a kind of preparation method of molecular sieve coating film, comprising:

[0058] Provide the substrate;

[0059] Mix 80-150 parts of molecular sieve, 1.6-3 parts of water-soluble polymer substance, 0.08-0.15 parts of thickener and water to obtain a molecular sieve coating mixture, the viscosity of which is 40-60mm 2 / s;

[0060] Apply the molecular sieve coating mixture evenly on the substrate;

[0061] The substrate coated with the molecular sieve coating is dried at a temperature of 150-300°C.

[0062] The invention adjusts the viscosity of the molecular sieve coating mixture to 40-60mm 2 / s, not only can make the mixture evenly coated on the substrate, but also can improve the coating efficiency. If the viscosity of the molecular sieve coating mixture is lower than 40mm 2 / s, then the adhesive force of molecular sieve coating reduces, and reduces the thickness of single coating molecular sieve coating, incre...

Embodiment 1

[0065] A molecular sieve coating film, comprising aluminum foil and a molecular sieve coating arranged on the aluminum foil;

[0066] The molecular sieve coating consists of the following raw materials in parts by weight:

[0067] Molecular sieve 80 parts

[0068] 1.6 parts of water-soluble polymer

[0069] Thickener 0.08 parts;

[0070] The average pore distance of the molecular sieve is 2.7-3.1nm, and the surface area is 720-750m 2 / g, the pore volume is 0.3-0.4ml / g, the thickener is carboxymethyl cellulose 1000mm 2 / s, the water-soluble macromolecular substance is carboxymethyl starch, and the molecular weight of the water-soluble macromolecular substance is 18000.

Embodiment 2

[0072] A molecular sieve coating film, comprising aluminum foil and a molecular sieve coating arranged on the aluminum foil;

[0073] The molecular sieve coating consists of the following raw materials in parts by weight:

[0074] Molecular sieve 90 parts

[0075] 1.8 parts of water-soluble polymer substances

[0076] Thickener 0.09 parts;

[0077] The average pore distance of the molecular sieve is 2.7-3.1nm, and the surface area is 720-750m 2 / g, the pore volume is 0.3-0.4ml / g, the thickener is hydroxyethyl cellulose, and the viscosity of the thickener is 1100mm 2 / s, the water-soluble macromolecular substance is starch acetate and hydrolyzed polyacrylamide, and the molecular weight of the water-soluble macromolecular substance is 19,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com