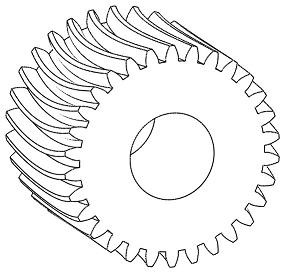

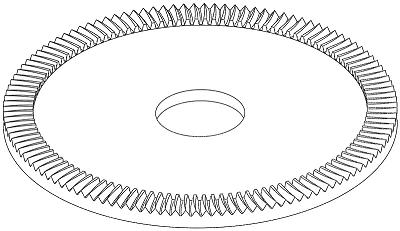

A transmission pair of arc tooth surface gear and its design method

A surface gear and arc tooth technology, applied in the field of arc tooth surface gear transmission pair and design, can solve the problems of low bearing capacity, large vibration noise, low coincidence degree, etc., and achieve strong bearing capacity, low vibration noise, and coincidence great effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

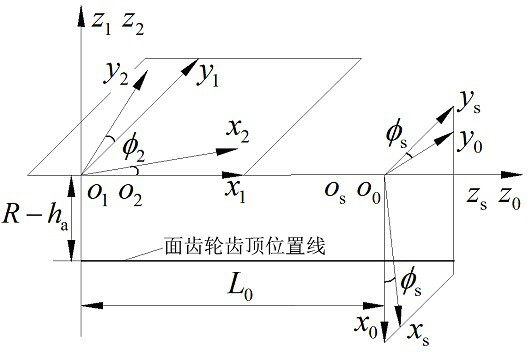

[0067] The basic parameters of the gear pair: imaginary tool gear modulus m=4, number of teeth N s =30, radius R of tooth line arc t =200, radius of indexing circle R=0.5mN s =60, pressure angle α s =20°, the number of teeth of arc tooth surface gear N 2 =120, the position parameter of the coordinate system is equal to the radius L of the pitch circle of the arc tooth surface gear 0 =240.

[0068] Step 1: The tooth surface equation r of the imaginary tool gear (end face involute tooth profile arc tooth cylindrical gear) s (θ s ,h) is

[0069]

[0070] In the formula, the symbols "±" correspond to the tooth surfaces on both sides of the alveolar. θ s is the angle parameter of the involute of the imaginary tool gear, θ s ∈[0,0.5371], h corresponds to the parameters of the imaginary tool gear tooth surface in its axial direction, h∈[-40, 40], R b is the radius of the base circle of the imaginary tool gear, R b =0.5mN s cosα s =56.3816, position angle θ s0 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com