Hydraulic servo test stand for automobile shock absorber

A hydraulic servo and shock absorber technology, which is applied to vehicle suspension/shock absorber testing and other directions, can solve the problems of rapid testing under difficult and multiple working conditions, small test speed range, poor comparability of results, etc., and achieves high reliability of test results. The effect of good work stability and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

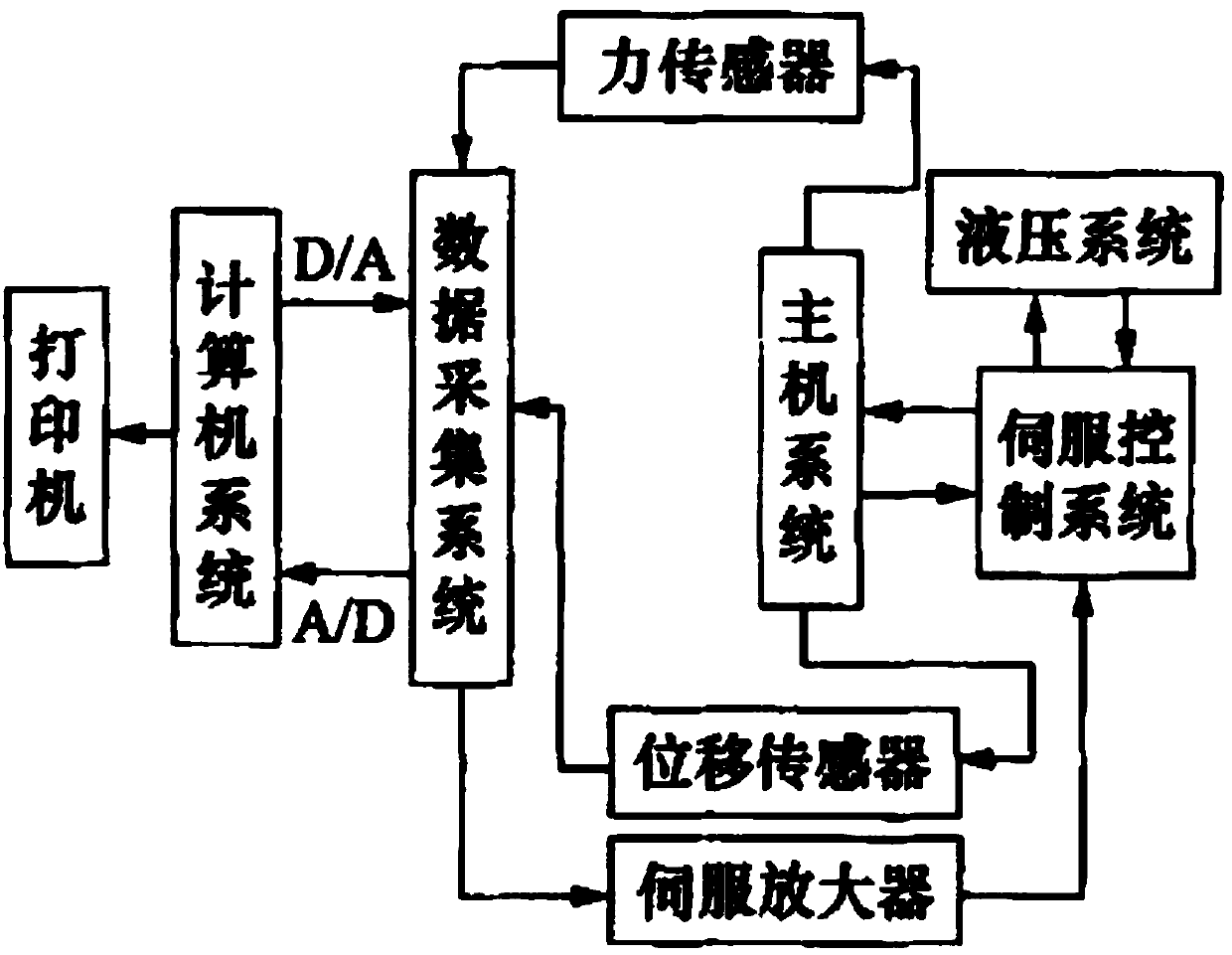

[0011] Such as figure 1 As shown, the present invention provides a hydraulic servo test bench for automobile shock absorbers, including a main engine system, a hydraulic system, a servo control system, a data acquisition system, and a computer system, and the main engine system includes a main engine, a main actuator, a servo actuator and a beam , the main engine is equipped with a dynamic and static bidirectional high-precision load sensor, a high-response linear differential transformer or displacement sensor is installed inside the main actuator, an electro-hydraulic servo valve is installed on the servo actuator, and the beam has hydraulic lifting and hydraulic locking function, it is easy to change the position of the beam according to the test piece; the hydraulic system includes an accumulator set on the main inlet and outlet pipeline of hydraulic oil and the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com