Non-contact type non-destructive detection method, terminal equipment and system for ballastless track defects

A ballastless track, non-contact technology, applied in the processing of detection response signals, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as inaccurate detection results of ballastless track defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

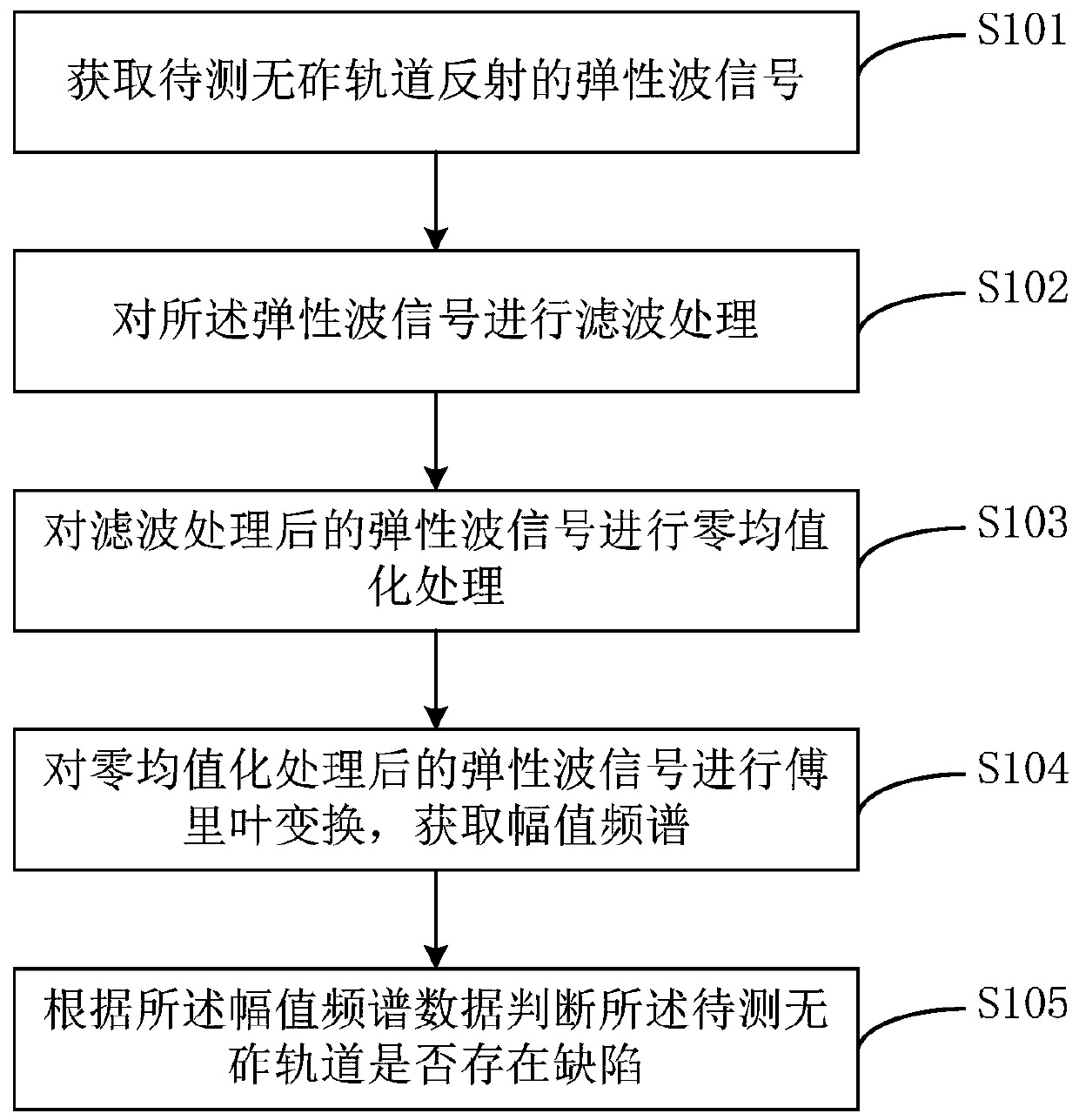

[0046] Please refer to figure 1 , figure 1 It is a schematic diagram of the implementation flow of a non-contact non-destructive detection method for ballastless track defects provided by Embodiment 1 of the present invention. The non-contact non-destructive detection method for ballastless track defects in this embodiment includes the following steps:

[0047] Step S101, acquiring the elastic wave signal reflected by the ballastless track to be tested.

[0048]In the embodiment of the present invention, when the surface of the ballastless track to be tested is knocked, a low-frequency elastic wave will be generated, and the elastic wave will propagate to the inside of the ballastless track to be tested. The medium surface of the ballast track will produce reflection, and the reflected elastic wave signal can be obtained. In one implementation manner, a small hammer or a small steel ball is used to manually tap the surface of the ballastless track to be tested to generate el...

Embodiment 2

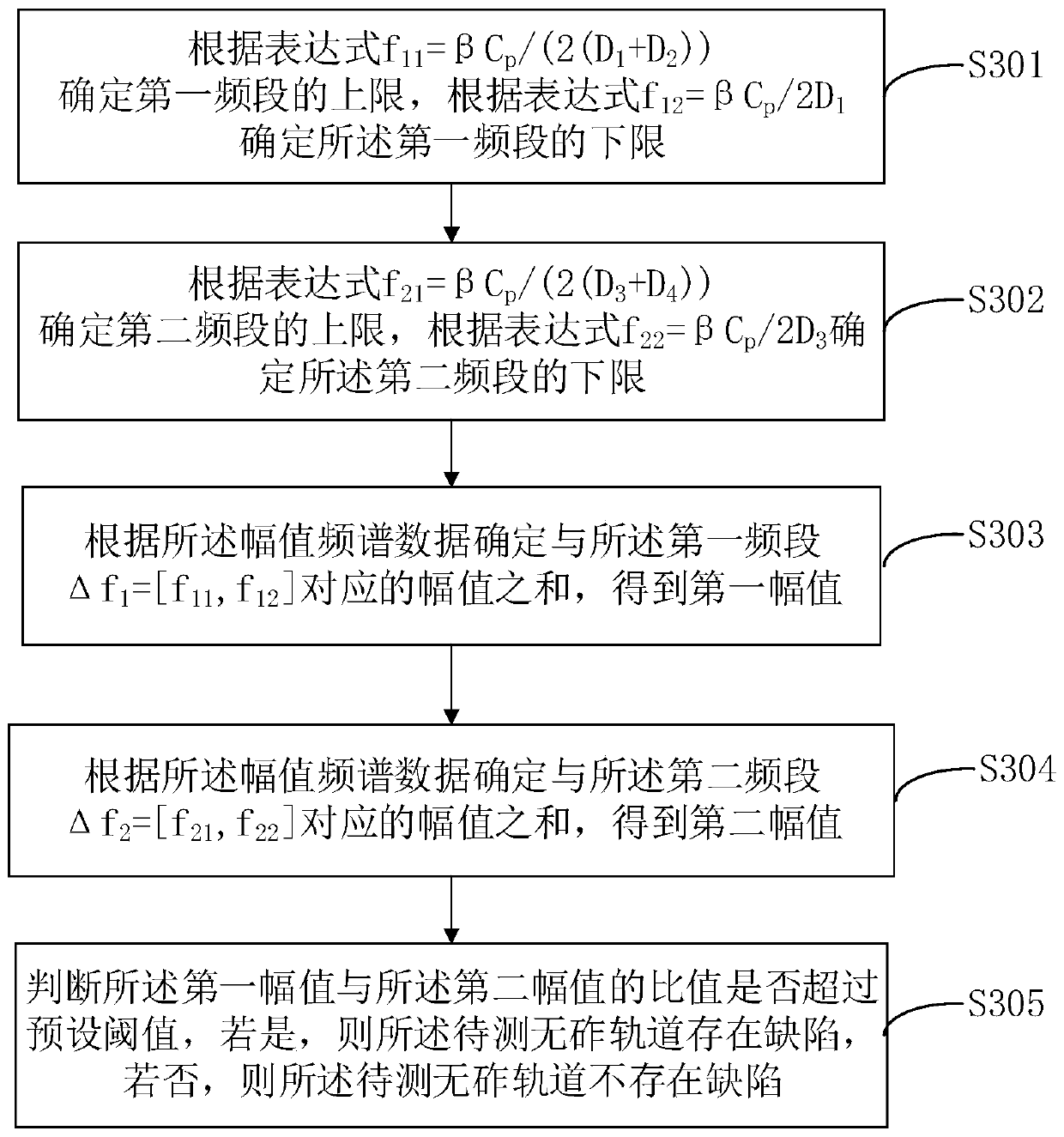

[0065] Please refer to image 3 , image 3 It is a schematic diagram of the implementation flow of a non-contact non-destructive testing method for ballastless track defects provided by Embodiment 2 of the present invention. figure 1 On the basis of the illustrated embodiment, this embodiment describes in detail the implementation of step S105, as image 3 Shown, the present embodiment method comprises the following steps:

[0066] Step S301, according to the expression Determine the upper limit of the first band, according to the expression A lower limit of the first frequency band is determined.

[0067] Step S302, according to the expression Determine the upper limit of the second band, according to the expression A lower limit of the second frequency band is determined.

[0068] Step S303, according to the amplitude spectrum data to determine the first frequency band Δf 1 =[f 11 , f 12 ] to obtain the first amplitude.

[0069] Step S304, according to the amp...

Embodiment 3

[0074] Please refer to Figure 4 , Figure 4 It is a schematic diagram of non-contact non-destructive testing terminal equipment for ballastless track defects provided by Embodiment 3 of the present invention. The ballastless track defect non-contact non-destructive testing terminal device 4 of this embodiment includes: a processor 401 , a memory 402 and a computer program 403 stored in the memory 402 and operable on the processor 401 . When the processor 401 executes the computer program 403, it realizes the steps in the embodiments of the non-contact non-destructive detection method for ballastless track defects, for example figure 1 Steps S101 to S105 are shown.

[0075] Exemplarily, the computer program 403 can be divided into one or more modules / units, and the one or more modules / units are stored in the memory 402 and executed by the processor 401 to complete this invention. The one or more modules / units may be a series of computer program instruction segments capable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com