Method for increasing stray light damage resistance threshold of inner wall of high-power laser system transmission pipeline

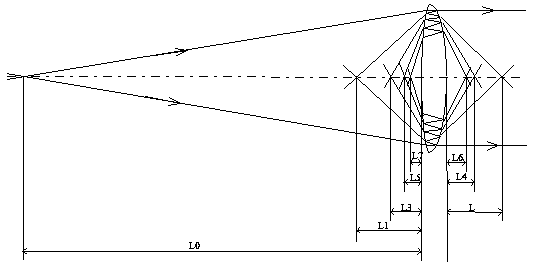

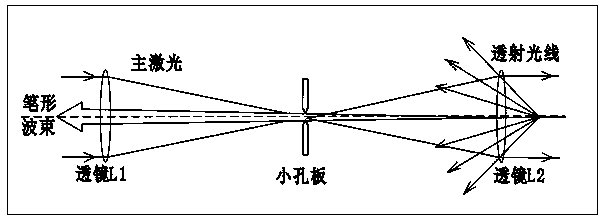

A laser system and transmission pipeline technology, applied in the field of laser optics, can solve the problems that plague the design of high-power laser systems, the laser damage threshold is difficult to exceed 0.5, etc., and achieve the effect of increasing the anti-stray light damage threshold and reducing the laser energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings.

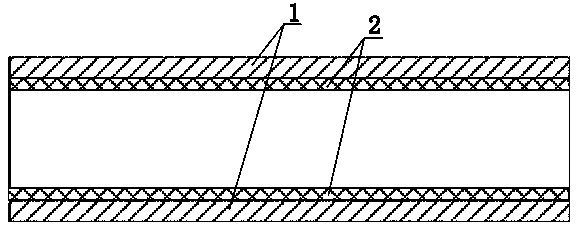

[0017] The inventor of the present application, based on the "divergent" type of stray light incident on the inner wall of the pipeline, has a large incident angle, and based on the principle of Fesnier reflection, coating a transmission pipeline made of aluminum alloy with a higher laser damage threshold Transparent silicone fluorine rubber material, structure such as image 3 As shown, the inner wall of the pipeline 1 is coated with a silicone fluorine rubber material coating 2;

[0018] The silicone fluorine rubber material of the present invention is prepared by the team of Professor Chen Xuhuang of Hubei University of Technology using ring-shaped hydrogen-containing fluorosilicone oil and vinyl ring under the action of Pt catalyst, using "liquid surface suspension method" and "step heating method". Published master's thesis: Lv Zhiyong, "Study on the Preparation and Reinforcement o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com